Cross-linkable microporous polymer gas separation membrane and preparation method thereof

A microporous polymer, gas separation membrane technology, applied in separation methods, filtration separation, semi-permeable membrane separation, etc., can solve the problems of reduced selectivity of separated gases, solubility restriction, poor solubility, etc., and achieve mild reaction conditions. , low price, high efficiency of synthesis reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

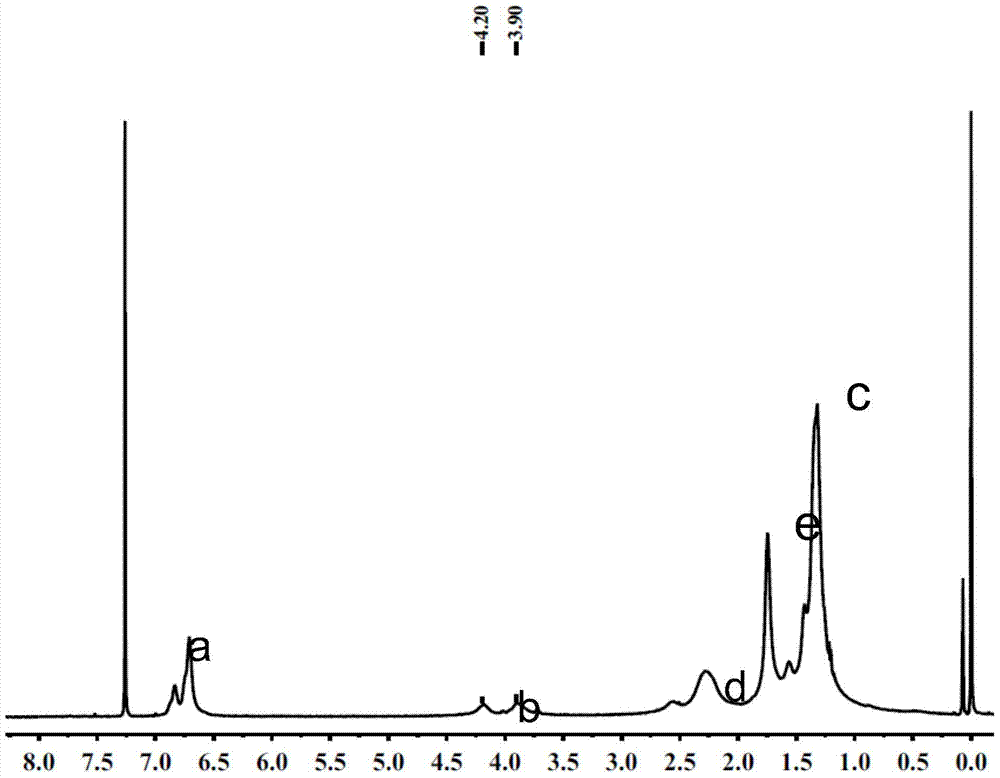

[0035] (1) Synthesis of polymer: under the protection of nitrogen atmosphere, the monomer CH 3 - TTSBI (3.684g, 0.01mol), TFTPN (2.001g, 0.01mol) and K 2 CO 3 (3.45g, 0.025mol) was dissolved in a mixed solvent of 18mL N,N-dimethylacetamide (DMAc) and 9mL toluene, stirred mechanically, and reacted at 150°C for 5 hours, then poured the viscous solution slowly Put into methanol, filter with suction to obtain a bright yellow fibrous polymer, then wash the polymer with methanol and distilled water for 3-5 times, and dry at 120° under vacuum to constant weight to obtain a yellow fluorescent polymer PIM-CH 3 , The conversion rate is 95%.

[0036] Its structural formula is as follows:

[0037]

[0038] (2) Preparation of brominated chain self-porous polymer membrane: 2.44g polymer PIM-CH 3 Dissolve in 250mL chlorobenzene, stir with magnetic force to form a homogeneous solution, add 1.82g N-bromosuccinimide and 0.16g azobisisobutyronitrile, react at 150°C for 5 hours, and precip...

Embodiment 2

[0048] (1) Synthesis of polymer: under the protection of nitrogen atmosphere, the monomer CH 3 - TTSBI (11.052g, 0.03mol), TFTPN (6.003g, 0.03mol) and K 2 CO 3 (11.04g, 0.08mol) was dissolved in a mixed solvent of 56mL N,N-dimethylacetamide (DMAC) and 11mL toluene, mechanically stirred, reacted at 160°C for 5 hours, and precipitated in methanol, followed by methanol and After washing with distilled water for 4 times, the polymer PIM-CH was obtained after filtration and drying 3 , The conversion rate was 93%.

[0049] Its structural formula is as follows:

[0050]

[0051] (2) Preparation of brominated chain self-porous polymer membrane: 7.3g polymer PIM-CH 3 Dissolve in 150mL chlorobenzene, stir with magnetic force to form a homogeneous solution, add 1.6g N-bromosuccinimide and 0.15g azobisisobutyronitrile, react at 130°C for 4 hours, and precipitate in methanol , after washing 4 times, filter and dry to obtain brominated polymer (bromination degree 50%).

[0052] Its...

Embodiment 3

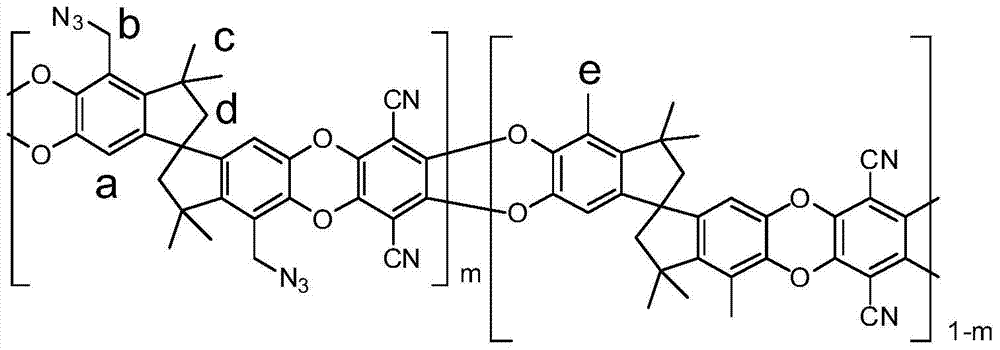

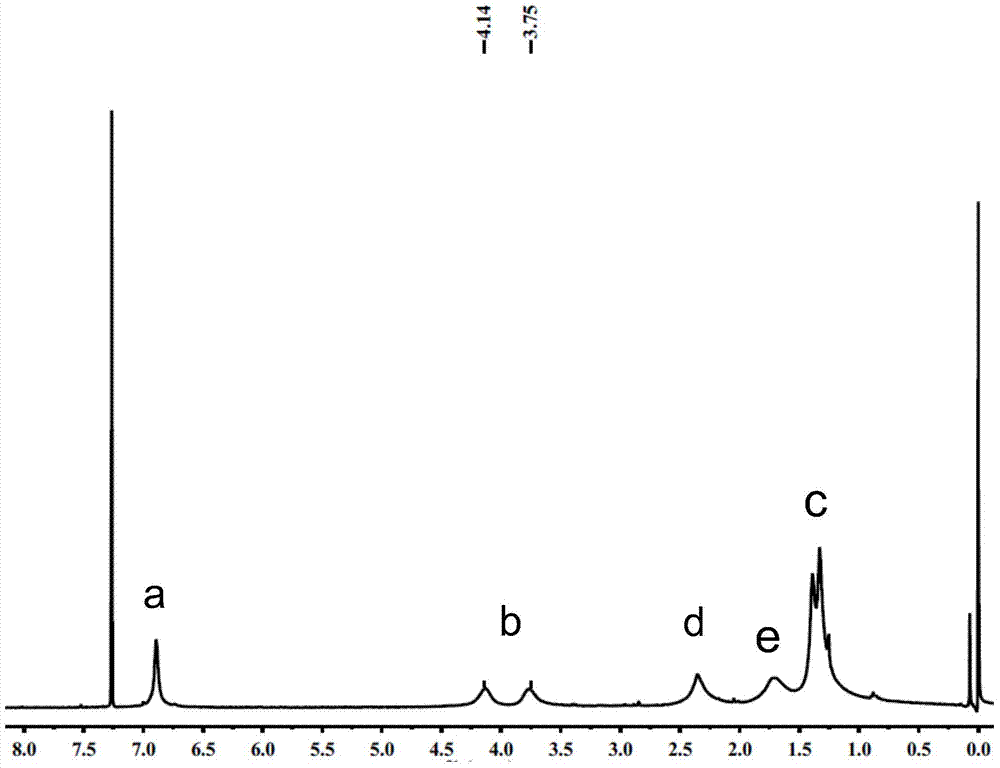

[0061] (1) Synthesis of polymer: under the protection of nitrogen atmosphere, the monomer CH 3 - TTSBI (3.684g, 0.01mol), TTSBI (6.808g, 0.02mol), TFTPN (6.003g, 0.03mol) and K 2 CO 3 (12.4g, 0.09mol) was dissolved in a mixed solvent of 55mL N,N-dimethylacetamide (DMAC) and 14mL toluene, mechanically stirred, reacted at 160°C for 5 hours, precipitated in a large amount of methanol, and washed for 4 times, filter and dry to obtain the polymer CO-PIM-CH 3 -1, the conversion rate is 93%.

[0062] Its structural formula is as follows (n=0.33):

[0063]

[0064] (2) Preparation of brominated chain self-porous polymer membrane: 4.72g polymer CO-PIM-CH 3 -1 was dissolved in 47mL of chlorobenzene, stirred by magnetic force to form a homogeneous solution, added 1.2g of N-bromosuccinimide and 0.11g of azobisisobutyronitrile, and reacted at 150°C for 5 hours. Precipitate in the medium, wash 5 times, filter and dry to obtain brominated polymer (bromination degree 33%). Its struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com