Preparation method of nitrogen-doped carbon nanofiber aerogel with inlaid molybdenum carbide particles

A technology of nitrogen-doped carbon and nanofibers, applied in chemical instruments and methods, nanotechnology for materials and surface science, nanotechnology, etc., can solve problems hindering practical applications, and achieve excellent catalytic performance for electrogenerating hydrogen, The effect of high specific surface area and easy scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

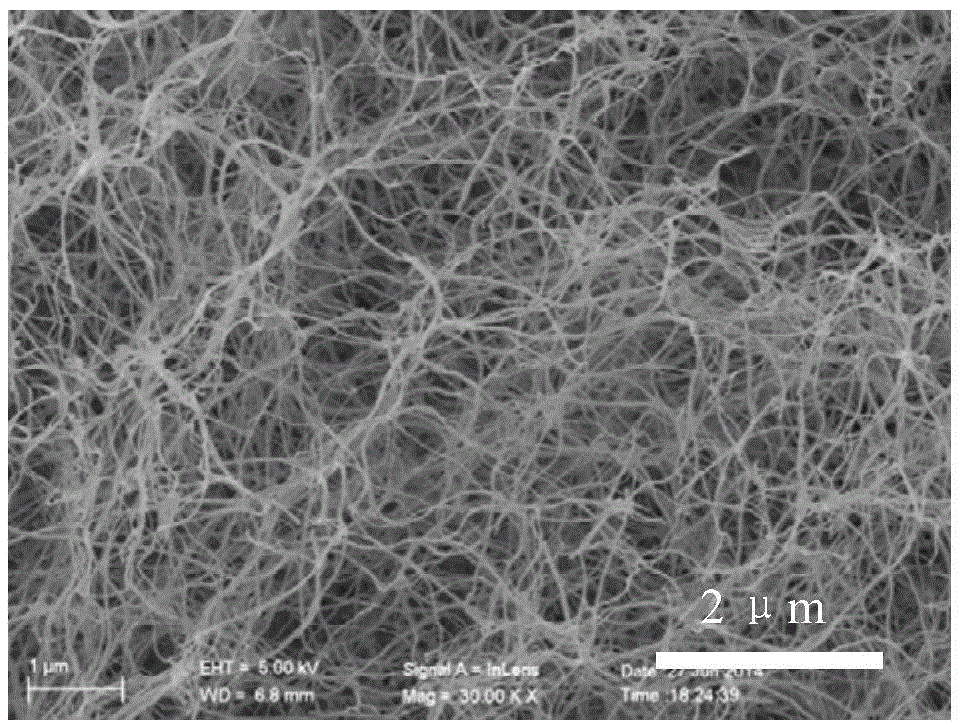

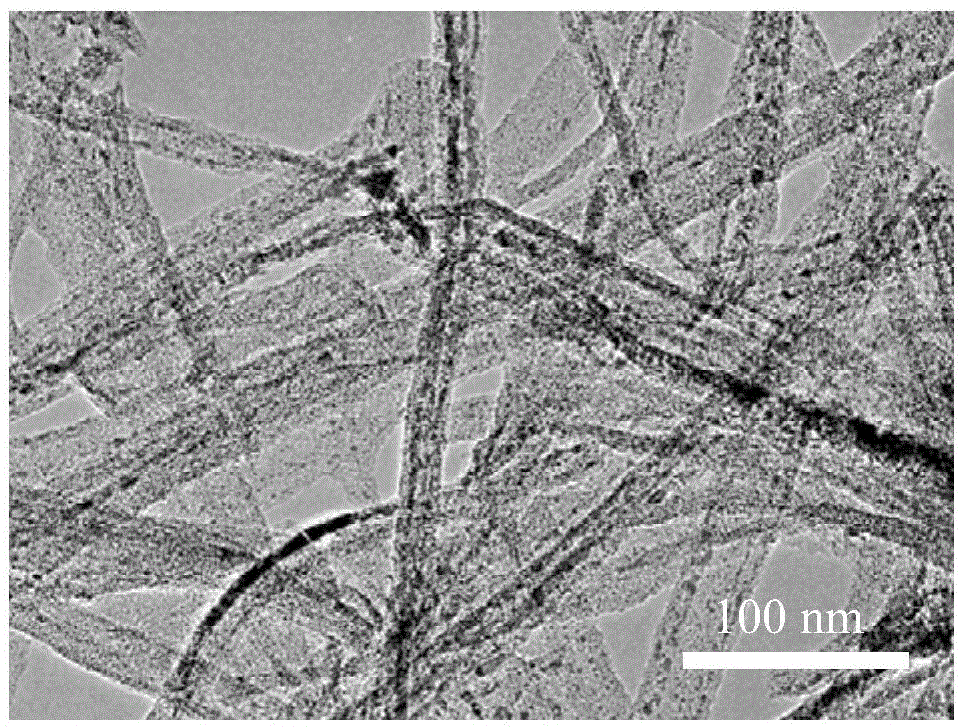

[0040] Take a commercially purchased 320×240×12mm 3 Large pieces of bacterial cellulose were soaked in deionized water for 5 days to remove acid, and the deionized water was replaced every day. Cut the large piece of bacterial cellulose after deacidification into 50×20×12mm 3The small pieces were obtained from pretreated bacterial cellulose for use. The pretreated bacterial cellulose was soaked in 2.5mM ammonium heptamolybdate aqueous solution for 3 days, then frozen with liquid nitrogen for 25 minutes, and then transferred to a freeze dryer for 4 days to obtain ammonium heptamolybdate hybrid bacterial cellulose gas. gel.

[0041] The ammonium heptamolybdate hybrid bacterial cellulose airgel obtained by freeze-drying was placed in a ceramic boat, and then transferred to a tube furnace for pyrolysis in a nitrogen atmosphere. °C / min reaches 500 °C after 4 hours, keeps at 500 °C for 1 hour, then increases to 800 °C at 5 °C / min, and keeps at 800 °C for 2 hours to fully carboniz...

Embodiment 2

[0052] Take a commercially purchased 320×240×12mm 3 Large pieces of bacterial cellulose were soaked in deionized water for 5 days to remove acid, and the deionized water was replaced every day. Cut the large piece of bacterial cellulose after deacidification into 50×20×12mm 3 The small pieces were obtained from pretreated bacterial cellulose for use. The pretreated bacterial cellulose was soaked in 7.5mM ammonium heptamolybdate aqueous solution for 3 days, then frozen with liquid nitrogen for 25 minutes, and then transferred to a freeze dryer to dry for 4 days to obtain white ammonium heptamolybdate hybrid bacterial fiber Plain airgel.

[0053] The ammonium heptamolybdate-hybrid bacterial cellulose airgel obtained by freeze-drying was placed in a ceramic boat and then transferred to a tube furnace. Pyrolysis under nitrogen atmosphere, first start from room temperature 20°C, reach 500°C at 2°C / min for 4 hours, keep at 500°C for 1 hour, then increase to 900°C at 5°C / min, and ...

Embodiment 3

[0056] Take a commercially purchased 320×240×12mm 3 Large pieces of bacterial cellulose were soaked in deionized water for 5 days to remove acid, and the deionized water was replaced every day. Cut the large piece of bacterial cellulose after deacidification into 50×20×12mm 3 The small pieces of the obtained pretreated bacterial cellulose are ready for use. Soak the pretreated bacterial cellulose in 5mmol / L ammonium heptamolybdate aqueous solution for 5 days, then freeze it with liquid nitrogen for 30min, and then transfer it to a freeze dryer to dry for 3 days to obtain white ammonium heptamolybdate hybrid bacteria Cellulose airgel.

[0057] The ammonium heptamolybdate-hybrid bacterial cellulose airgel obtained by freeze-drying was placed in a ceramic boat and then transferred to a tube furnace. Pyrolysis under nitrogen atmosphere, first start from room temperature at 20°C, reach 500°C at 1°C / min for 8 hours, keep at 500°C for 2 hours, then increase to 1000°C at 5°C / min, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com