Coal chemical industry high-COD and high-salinity concentrated liquor crystallizing and drying method

A drying method, a technology of coal chemical industry, applied in the field of coal chemical industry, can solve the problems of heat transfer coefficient drop, difficult crystallization, viscosity increase, etc., and achieve the effects of obvious treatment effect, high degree of automation, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

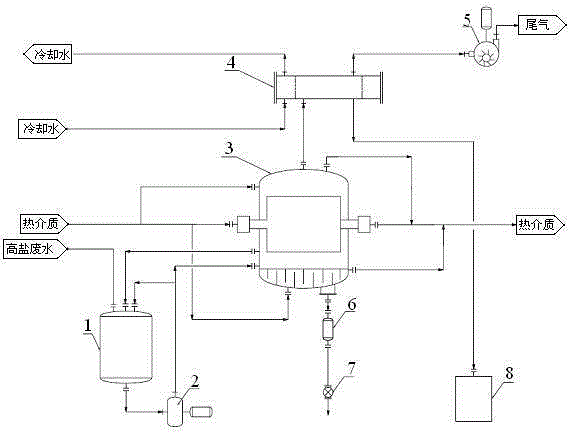

[0023] Such as figure 1 Shown, a kind of coal chemical industry high COD, high salt concentrated liquid crystallization and drying method, comprises the following steps:

[0024] (1) Send the high-COD and high-salt concentrated liquid of the coal chemical industry stored in the liquid storage tank 1 at normal temperature into the vacuum drum dryer 3 through the feed pump 2 at the bottom of the liquid storage tank 1; at the same time, the temperature is 150~ The heating medium at 198°C is fed into the central shaft, bottom tray and top jacket of the vacuum drum dryer 3, and the heat is indirectly transferred to the high-COD and high-salt concentrated liquid of the coal chemical industry to evaporate the water in the high-salt concentrated liquid , to obtain solid salt at a temperature of 40-60°C and gaseous wastewater at a temperature of 50-90°C.

[0025] Among them: Coal chemical high COD, high salt concentrated liquid refers to the concentrated liquid with a COD content of 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com