Method for producing organic carbon fertilizer through photocatalytic and oxidized organic wastewater

A photocatalytic oxidation and organic wastewater technology, applied in the field of water treatment, can solve the problems of difficult catalyst recovery, narrow light absorption range, low light energy utilization rate, etc., to improve crop yield and agricultural product quality, low selectivity, and catalytic efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

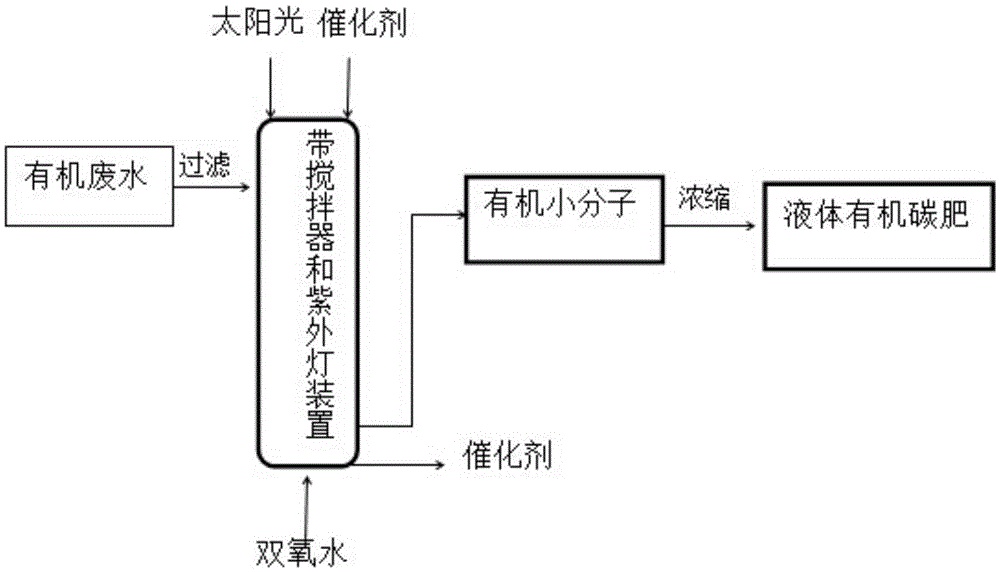

[0047] Using molasses alcohol waste liquid as raw material to produce organic carbon fertilizer, the production process is as follows:

[0048] (1) Provide a photocatalytic oxidation reaction container with an agitator and a remote-controlled timing ultraviolet lamp. There is a water outlet with a filter membrane and a catalyst outlet at the bottom of the container, a detachable plastic cover on the top, and a waste liquid inlet at the upper end of the container;

[0049] (2) Add a certain amount of photocatalyst TiO in the reactor 2 / SiO 2 / Fe 3 o 4 Composite particles, ensure that its concentration in the reaction process is at 1.2g / L, then pump molasses alcohol waste liquid (alcohol waste liquid has almost no waste residue, and can not be filtered) into the reactor, add 4% concentration of 80% For hydrogen peroxide, turn on the mixer to mix the molasses alcohol waste liquid, hydrogen peroxide and catalyst evenly, stir for 10 minutes to mix the solution evenly, and avoid ...

Embodiment 2

[0056] To produce liquid organic carbon fertilizer with amino acid production waste liquid as raw material, the production process is as follows:

[0057] (1) Provide a photocatalytic oxidation reaction container with an agitator and a remote-controlled timing ultraviolet lamp. There is a water outlet with a filter membrane and a catalyst outlet at the bottom of the container, a detachable plastic cover on the top, and a waste liquid inlet at the upper end of the container;

[0058] (2) Add a certain amount of photocatalyst TiO in the reactor 2 / SiO 2 / Fe 3 o 4 Composite particles, to ensure that its concentration in the reaction process is 1.2g / L, then the amino acid production waste liquid is coarsely filtered to remove solid insolubles and then pumped into the reactor, add 4% hydrogen peroxide with a concentration of 80%, and turn on the stirrer to Amino acid production waste liquid, hydrogen peroxide and catalyst are mixed evenly, and stirred for 10 minutes to make the ...

Embodiment 3

[0065] Using papermaking black liquor as raw material to produce liquid organic carbon fertilizer, the production process is as follows:

[0066] (1) Provide a photocatalytic oxidation reaction container with an agitator and a remote-controlled timing ultraviolet lamp. There is a water outlet with a filter membrane and a catalyst outlet at the bottom of the container, a detachable plastic cover on the top, and a waste liquid inlet at the upper end of the container;

[0067] (2) Add a certain amount of photocatalyst TiO in the reactor 2 / SiO 2 / Fe 3 o 4 Composite particles, ensure that its concentration in the reaction process is 1.2g / L, then coarsely filter the papermaking black liquor to remove solid insolubles, pump it into the reactor, add 4% hydrogen peroxide with a concentration of 80%, and turn on the agitator to make the papermaking Mix the black liquor, hydrogen peroxide and the catalyst evenly, stir for 10 minutes to make the solution evenly mixed, and avoid light ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com