Method of preparing porous phosphor absorbing ceramic particle from sludge in water supply plant

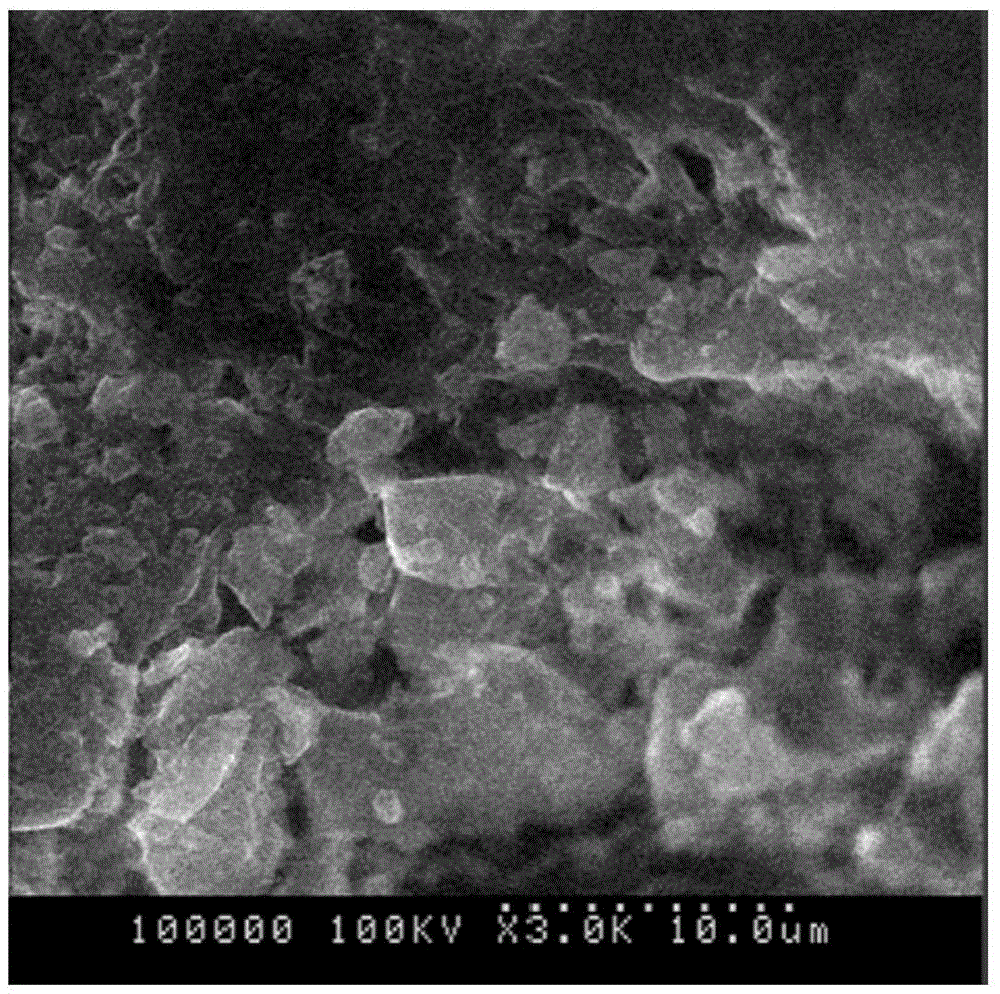

A water supply plant sludge and ceramsite technology, which is applied in the direction of adsorption of water/sewage treatment, application, ceramic products, etc., can solve the problems of low addition of water supply sludge and low specific surface area, and achieve high use value and large specific surface area , the effect of protecting land resources and water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A method for preparing porous phosphorus-absorbing ceramsite with water supply plant sludge, the specific method is as follows:

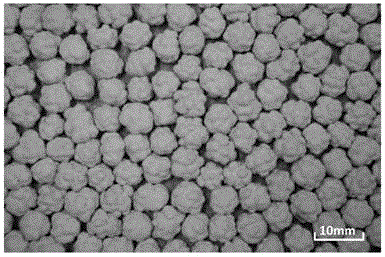

[0023] The production process of sludge ceramsite in water supply plant mainly includes four stages of raw material pretreatment, pelleting, firing and cooling.

[0024] (1) Pretreatment

[0025] Naturally air-dry the sludge from the water supply plant, put it into a pulverizer, grind it, and sieve it with a 100-mesh standard sieve (with a sieve size of 0.15mm).

[0026] (2) into a ball

[0027] Mix the sludge and clay from the water supply plant evenly at a mass ratio of 3:1, add them to the ball forming machine to prepare raw meal balls, and spray a solution with a mass fraction of 0.5% sodium silicate as a binder during the ball forming process, sodium silicate The amount of solution used is 10% of the mass of the ball forming material, and the speed of the ball forming machine is controlled to be 40r / min.

[0028] (3) dry

[0029] Aft...

Embodiment 2

[0034] A method for preparing porous phosphorus-absorbing ceramsite with water supply plant sludge, the specific method is as follows:

[0035] The production process of sludge ceramsite in water supply plant mainly includes four stages of raw material pretreatment, pelleting, firing and cooling.

[0036] (1) Pretreatment

[0037] Naturally air-dry the sludge from the water supply plant, put it into a pulverizer, grind it, and sieve it with a 120-mesh standard sieve (with a sieve size of 0.125mm).

[0038] (2) into a ball

[0039] Mix the sludge and clay from the water supply plant evenly at a mass ratio of 4:1, add them to the ball forming machine to prepare raw meal balls, and spray a solution with a mass fraction of 2.0% sodium silicate as a binder during the ball forming process, sodium silicate The amount of the solution is 15% of the mass of the ball forming material, and the speed of the ball forming machine is controlled to be 30r / min.

[0040] (3) dry

[0041] Aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| cylinder compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com