A method for separating and purifying naimamectin by high performance liquid chromatography

A high-performance liquid chromatography and naimectin technology, which is applied in the field of high-performance liquid chromatography for purifying moxidectin precursor naimactin, can solve the problems of high cost, large proportion of organic solvents, complicated procedures and the like, and achieves the The effect of shortened production cycle, short purification time and fewer process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

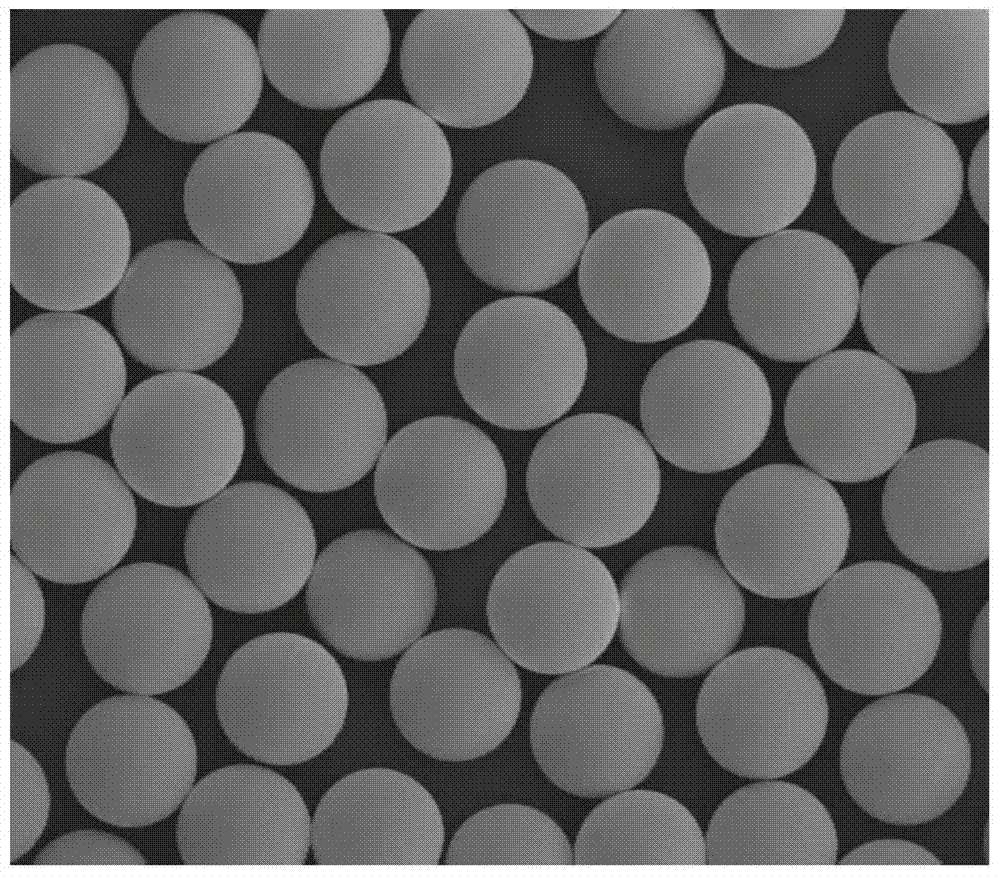

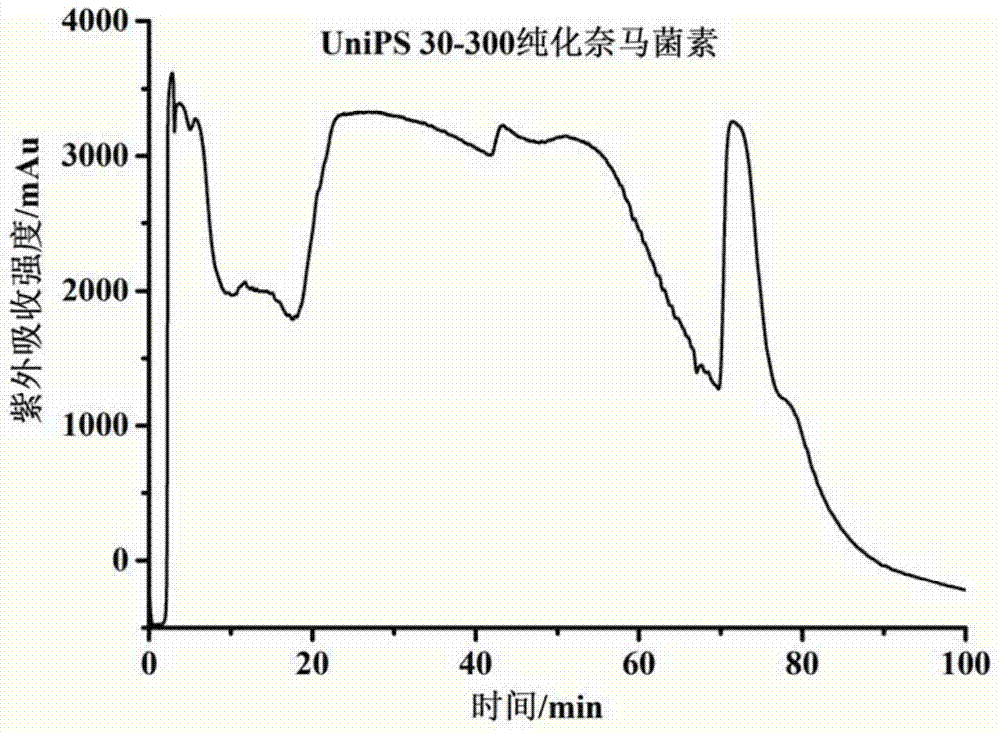

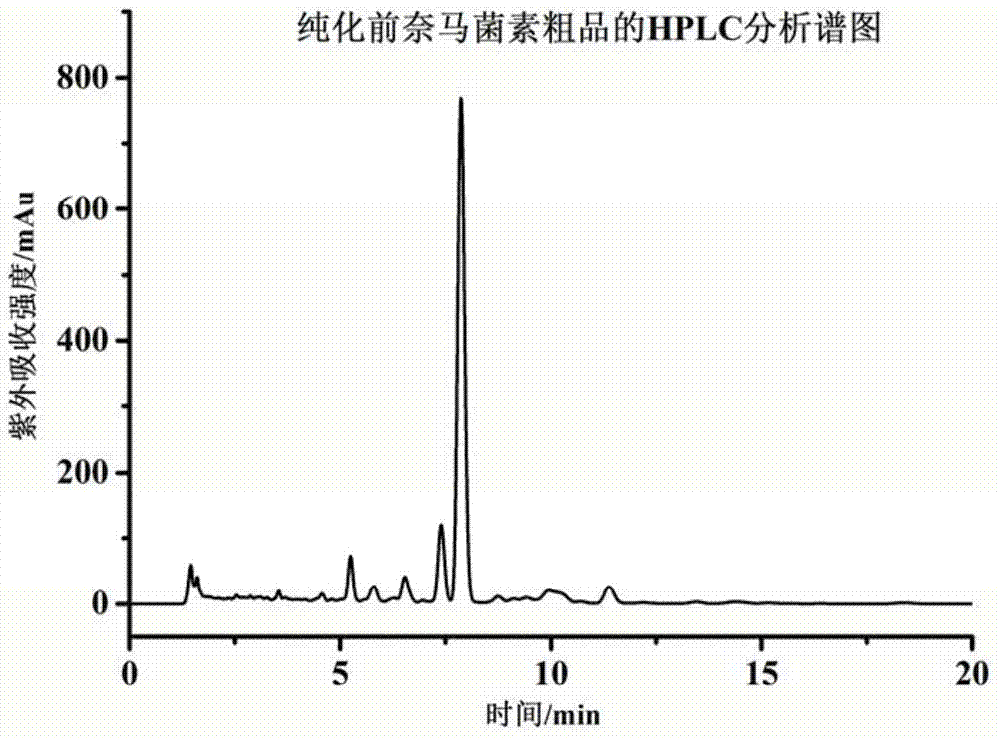

Embodiment 1

[0032] Purification of naimamectin: using a (4.6×250)mm chromatographic column, UniPS 30-300 (polystyrene-divinylbenzene copolymer particle size 30±1.5μm, Suzhou Nanoway Technology Co., Ltd.) as the separation The filler is purified, the column volume is 4.1ml, and the column is equilibrated with 68-72% acidic ethanol aqueous solution. The mobile phase A is an aqueous hydrochloric acid solution with a pH value of 2 to 3, and the mobile phase B is ethanol with a pH of 2 to 3. Different percentages of the mobile phase A and mobile phase B are used to form the mobile phase used for elution. The crude product of naimamectin (purity 65-68%) is firstly dissolved with ethanol aqueous solution, mixed and then filtered with a 0.45 μm filter membrane. The concentration is 100mg / ml, the sample volume is 0.42ml, and the sample volume is about 10mg / ml. The sample loading flow rate is 1ml / min, first use 68-72% acidic ethanol aqueous solution to wash 9-10 column volumes, and 78-80% acidic e...

Embodiment 2

[0034] Purification of naimamectin: using a (4.6×250)mm chromatographic column, UniPS 40-300 (polystyrene-divinylbenzene copolymer particle size 40±1.5μm, Suzhou Navi Technology Co., Ltd.) as the separation The filler is purified, the column volume is 4.1ml, and the column is equilibrated with 68-72% acidic ethanol aqueous solution. The mobile phase A is an aqueous acetic acid solution with a pH value of 2 to 3, the mobile phase B is ethanol with a pH of 2 to 3, and the mobile phase is a mixture of ethanol and acetic acid solutions in different proportions. The crude product of naimamectin (purity 65-68%) is firstly dissolved with ethanol aqueous solution, mixed and then filtered with a 0.45 μm filter membrane. The concentration is 100mg / ml, the sample volume is 0.42ml, and the sample volume is about 10mg / ml. The sample loading flow rate is 1ml / min, first use 68-72% acidic ethanol aqueous solution to wash 9-10 column volumes, and 78-80% acidic ethanol aqueous solution to elut...

Embodiment 3

[0036] Purification of naimamectin: adopt (4.6×250) mm chromatographic column, NM 100 filler (polystyrene-divinylbenzene copolymer, microsphere particle size 50-150 μm, pore size Suzhou Nawei Technology Co., Ltd.) was used as a separation and purification filler, with a column volume of 4.1 ml, and the column was equilibrated with 72% acidic ethanol aqueous solution. The mobile phase A is a hydrochloric acid solution with a pH of 2-3, and the mobile phase B is ethanol with a pH of 2-3. The crude product of naimamectin (purity 65-68%) is firstly dissolved with ethanol aqueous solution, mixed and then filtered with a 0.45 μm filter membrane. The concentration is 100mg / ml, the sample volume is 0.42ml, and the sample volume is about 10mg / ml. The sample loading flow rate is 1ml / min, first use 72% acidic ethanol aqueous solution to wash 9-10 column volumes, 78-80% acidic ethanol aqueous solution to elute target components for 6-7 column volumes, and finally use 90%- 95% acidic eth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com