Preparation method for phase-separation induced porous super-hydrophobic coating material

A super-hydrophobic coating and phase separation technology, applied in the direction of coating, can solve the problems of cumbersome preparation process, harsh process conditions, insufficient high temperature resistance, etc., and achieve the effect of simple preparation process, low cost, and enhanced weather resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) Weigh hexafluorobutyl methacrylate (G02), ethylene glycol dimethacrylate (EDMA), 1,4-butanediol (BDO) and N-methyl-2 -pyrrolidone (NMP) (where m (G02) :m (EDMA) =50:50,m (G02+EDMA) :m (BDO+NMP) =50:50,m (BDO) :m (NMP) Take 35:65, 40:60, 45:55, 50:50, 60:40 series ratio respectively, m (G02+EDMA) +m (BDO+NMP) 6g), azobisisobutyronitrile (AIBN) 2% (relative to the total mass of polymerized monomers) in a 25mL beaker;

[0026] 2) Place the beaker in step 1) in an ultrasonic cleaner for 30 minutes of ultrasonic treatment until a uniform and transparent solution is formed;

[0027] 3) Take 0.2mL of the solution in step 2) and inject it between the pretreated glass substrate and the polytetrafluoroethylene plate to obtain the sample;

[0028] 4) Place the sample prepared in step 3) in a blast drying oven, set the temperature at 80°C, heat-initiate the polymerization reaction for 20 hours, end the reaction, and cool to room temperature;

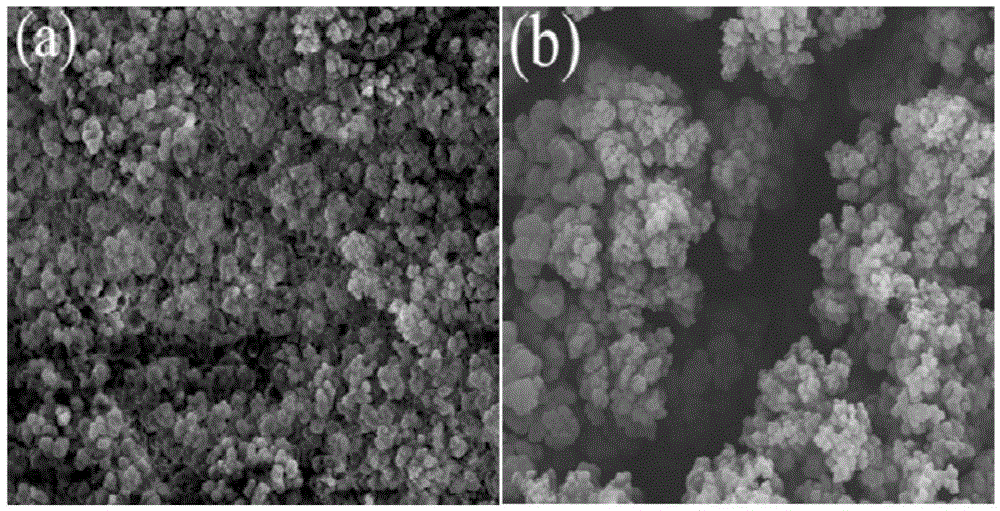

[0029] 5) Separate the gla...

Embodiment 2

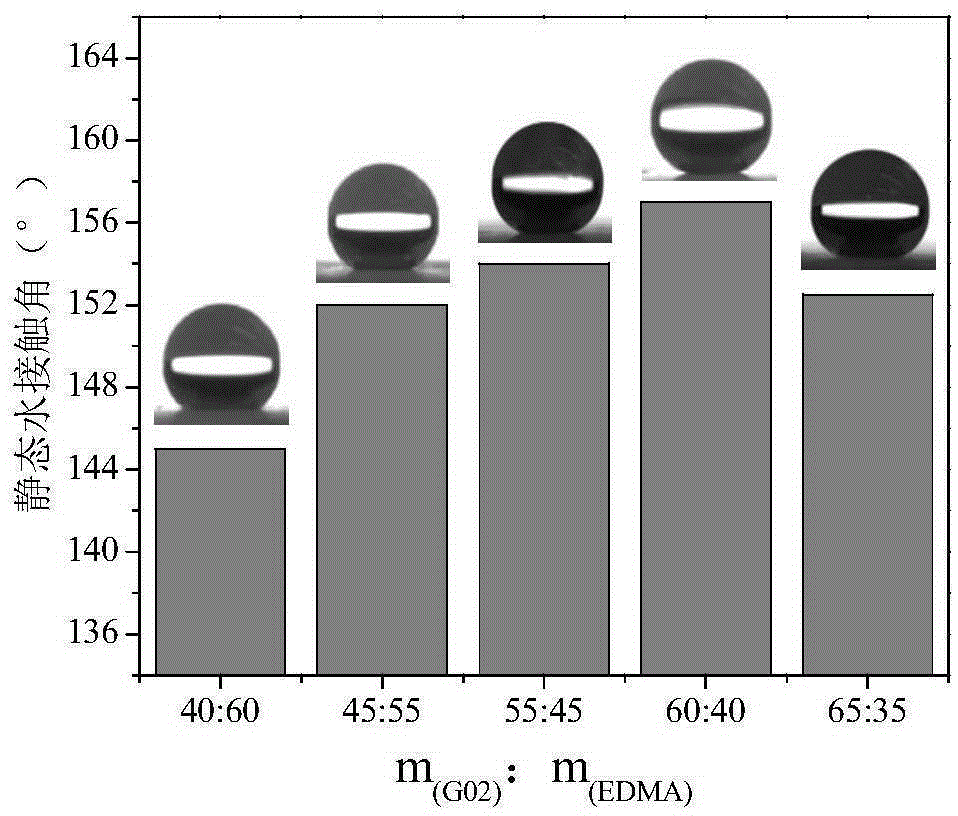

[0031] 1) Weigh a certain amount of hexafluorobutyl methacrylate (G02), ethylene glycol dimethacrylate (EDMA), 1,4-butanediol (BDO) and N-methacrylate in sequence according to a certain mass ratio Base-2-pyrrolidone (NMP) (where m (BDO) : (NMP) =40:60, m (G02+EDMA) :m (BDO+NMP) =50:50, m (G02) :m (EDMA) Take the ratio of 40:60, 45:55, 55:45, 60:40, 65:35 series, m (G02+EDMA)+m (BDO+NMP) 6g), azobisisobutyronitrile (AIBN) 2% (relative to the total mass of polymerized monomers) in a 25mL beaker;

[0032] 2) Place the beaker in step 1) in an ultrasonic cleaner for 30 minutes of ultrasonic treatment until a uniform and transparent solution is formed;

[0033] 3) Take 0.2mL of the solution in step 2) and inject it between the pretreated glass substrate and the polytetrafluoroethylene plate to obtain the sample;

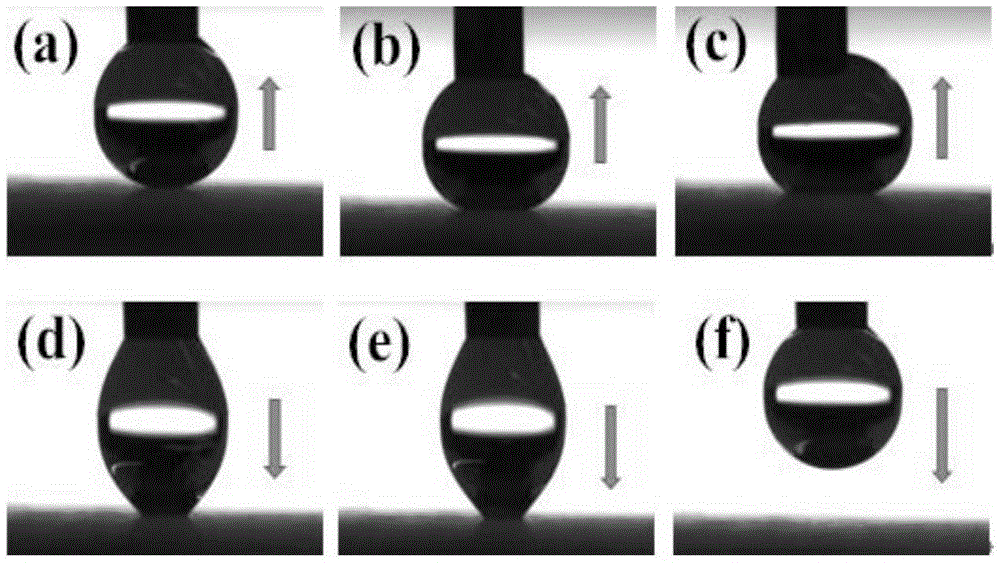

[0034] 4) Place the sample prepared in step 3) in a blast drying oven, set the temperature at 80°C, heat-initiate the polymerization reaction for 20 hours, end the...

Embodiment 3

[0037] 1) Weigh a certain amount of hexafluorobutyl methacrylate (G02), ethylene glycol dimethacrylate (EDMA), 1,4-butanediol (BDO) and N-methacrylate in sequence according to a certain mass ratio Base-2-pyrrolidone (NMP) (where m (G02) :m (EDMA) =60:40,m (BDO) :m (NMP) =40:60, m (G02+EDMA) :m (BDO+NMP) =45:55, m (G02+EDMA) +m (BDO+NMP) 6g), azobisisobutyronitrile (AIBN) 2% (relative to the total mass of polymerized monomers) in a 25mL beaker;

[0038] 2) Place the beaker in step 1) in an ultrasonic cleaner for 30 minutes of ultrasonic treatment until a uniform and transparent solution is formed;

[0039] 3) Take 0.2mL of the solution in step 2) and inject it between the pretreated glass substrate and the polytetrafluoroethylene plate to obtain the sample;

[0040] 4) Place the sample prepared in step 3) in a blast drying oven, set the temperature at 80°C, heat-initiate the polymerization reaction for 20 hours, end the reaction, and cool to room temperature;

[0041] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com