High-performance modified plastic

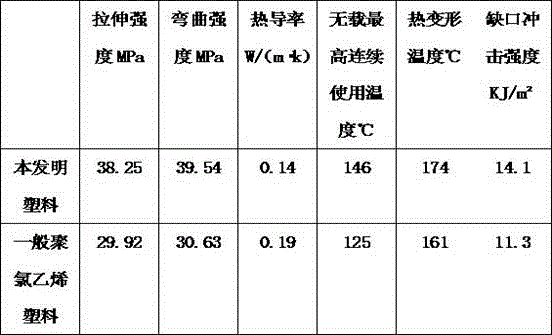

A high-performance, modified technology, applied in the field of plastic production, can solve the problems of decreased physical and mechanical properties, poor impact resistance, small branching degree, etc., to improve heat resistance and aging resistance, good impact resistance, and weather resistance sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] A high-performance modified plastic made of the following components in parts by weight: 45 parts of polyvinyl chloride, 25 parts of polypropylene, 10 parts of high alumina bauxite, 8 parts of aluminum powder, 6 parts of calcium hexaaluminate, diatom 5 parts of soil, 3 parts of dispersant, 2 parts of heat stabilizer, 2 parts of plasticizer.

[0014] Further, the aluminum powder is heated in a 60-65° C. water bath for 1-1.5 hours and then dried.

[0015] Further, the dispersant is sodium hexametaphosphate.

[0016] Further, the heat stabilizer is calcium stearate.

[0017] Further, the plasticizer is a citrate ester.

[0018] Further, the calcium hexaaluminate and the nano barium sulfate solution with a concentration of 8.5% are blended and heated for 2 hours; the particle size of the nano barium sulfate in the nano barium sulfate solution is 50-60 nm.

[0019] Furthermore, the high alumina bauxite is pretreated: the high alumina bauxite is mixed with 5 parts by weight of coal gan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com