Method for preparing bio-oil through co-pyrolysis catalytic hydrogenation by means of algae and waste rubber

A waste rubber, catalytic hydrogenation technology, applied in the direction of refining hydrocarbon oil, petroleum industry, processing hydrocarbon oil, etc., can solve the problem of little research on co-pyrolysis of algae biomass as raw material, and achieve the goal of alleviating the increasing shortage and reducing oxygen The effect of content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

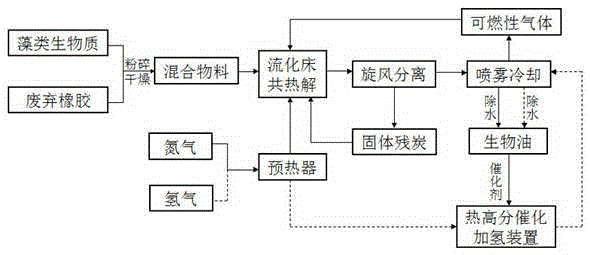

Method used

Image

Examples

Embodiment 1

[0027] (1) Crush the chlorella and waste rubber tires into particles with a particle size of 1 mm and mix them evenly, and dry them in an electric blast drying oven for 24 hours, and control the moisture content below 5%;

[0028] (2) Using nitrogen as the carrier gas and quartz sand as the heat carrier, send the mixed material into the fluidized bed reactor for co-pyrolysis, the reaction temperature is 500°C, and the gas residence time is 2s;

[0029] (3) Cyclone separate the biomass pyrolysis steam with solid carbon residue, and then use spray cooling to condense the pyrolysis steam into crude bio-oil at about 300°C, and use it for dehydration treatment;

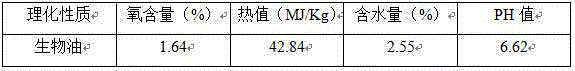

[0030] (4) Put the crude bio-oil after water removal and the HZSM-5 molecular sieve catalyst with a silicon / aluminum ratio of 25 together in a thermal high-resolution catalytic hydrogenation device for catalytic hydrogenation modification. The reaction temperature is 300°C and the reaction pressure is 10MPa, the reaction t...

Embodiment 2

[0035] (1) Crush blue algae and waste rubber tires into particles with a particle size of 0.5 mm and mix them evenly, and dry them in an electric blast drying oven for 12 hours, and control the moisture content below 10%;

[0036] (2) Using nitrogen as the carrier gas and quartz sand as the heat carrier, send the mixed material into the fluidized bed reactor for co-pyrolysis, the reaction temperature is 550°C, and the gas residence time is 2s;

[0037] (3) Cyclone separate the biomass pyrolysis steam with solid carbon residue, and then use spray cooling to condense the pyrolysis steam into crude bio-oil at about 325°C, and use it for dehydration treatment;

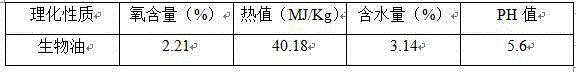

[0038] (4) Put the crude bio-oil after water removal and the HZSM-5 molecular sieve catalyst with a silicon / aluminum ratio of 25 together in a thermal high-resolution catalytic hydrogenation unit for catalytic hydrogenation modification. The reaction temperature is 325°C and the reaction pressure is 5MPa, the reaction time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com