Coal fired chain grate hot-blast stove and application thereof

A chain grate, hot blast stove technology, applied in air heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of coal-fired thermal efficiency, high energy consumption, waste of energy, etc., and achieve product quality. Stable and reliable, high degree of automation, good control stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

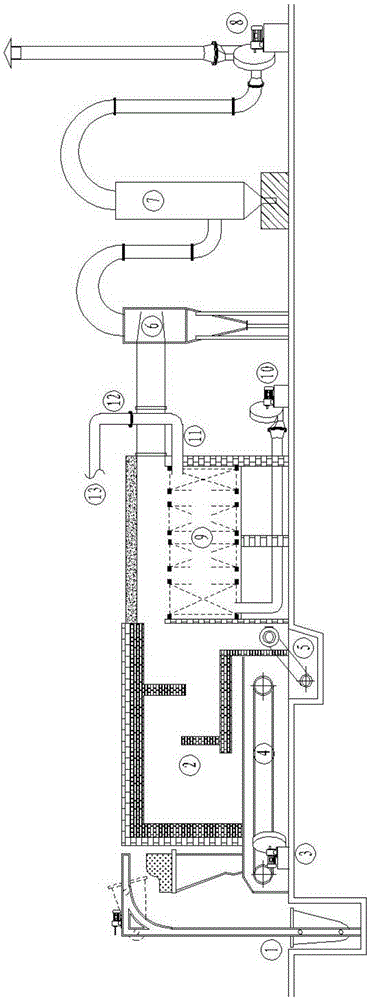

[0025] figure 1 The structure of the coal-fired chain grate hot blast stove in this embodiment is shown, which includes a furnace 2, a chain grate 4 and a clean air heat exchanger 9. The hot blast stove is a horizontal furnace, and fuel is arranged above the chain grate. At the inlet, the fuel coal is lifted by the upper coal hopper 1 and falls on the grate 4; a combustion-supporting fan 3 is installed under one end of the chain grate where fuel is added, and a slag extractor 5 is installed under the other end of the grate 4; clean air heat exchange Device 9 is a tube-and-tube heat exchanger with a tube diameter of 57mm. The tube side is a clean air channel, and the clean air and flue gas flow in parallel. The flue gas outlet and the clean air outlet are located on the same side of the furnace wall of the hot blast stove. The outlet is sequentially connected to the cyclone dust collector 6, the water film dust collector 7, the induced smoke fan 8 and the chimney through the pi...

Embodiment 2

[0028] The coal-fired chain grate type hot blast stove of application embodiment, the method for drying ascorbic acid-2-phosphate:

[0029] Coal with a calorific value above 4800kcal / kg is used as fuel and sent to the hot blast stove for combustion. By controlling the forward speed of the chain grate, the flow rate of the combustion-supporting fan and the smoke-inducing fan, the temperature of the flue gas in the furnace is 480-500°C, and the flue gas enters the exchange The heater heats the clean air in the tube. By controlling the flow of clean air, clean hot air with a temperature of 220-230°C is obtained. The clean hot air is sent to the host of the airflow dryer for drying of ascorbic acid-2-phosphate.

[0030] The system runs smoothly and has a high degree of automation. Compared with the traditional coal-fired steam boiler heating process, it can save half of the manpower and significantly improve the production efficiency. This system breaks the traditional steam prehea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com