Patents

Literature

33results about How to "Up and down stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

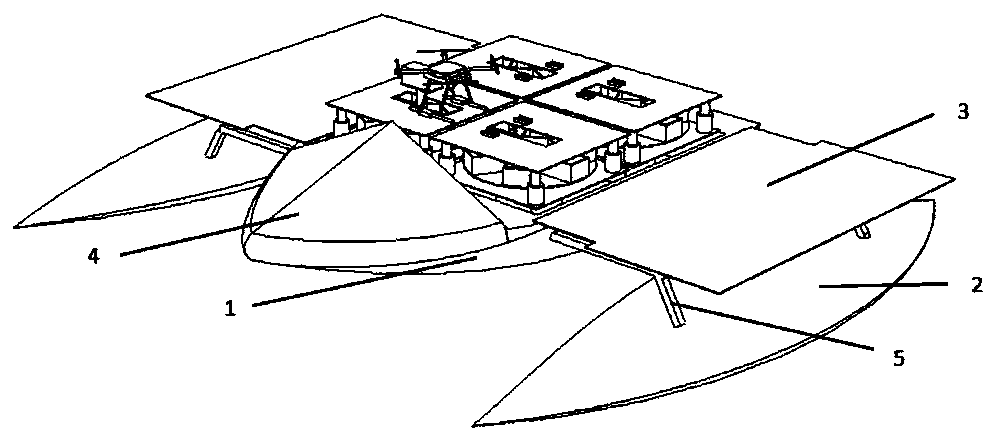

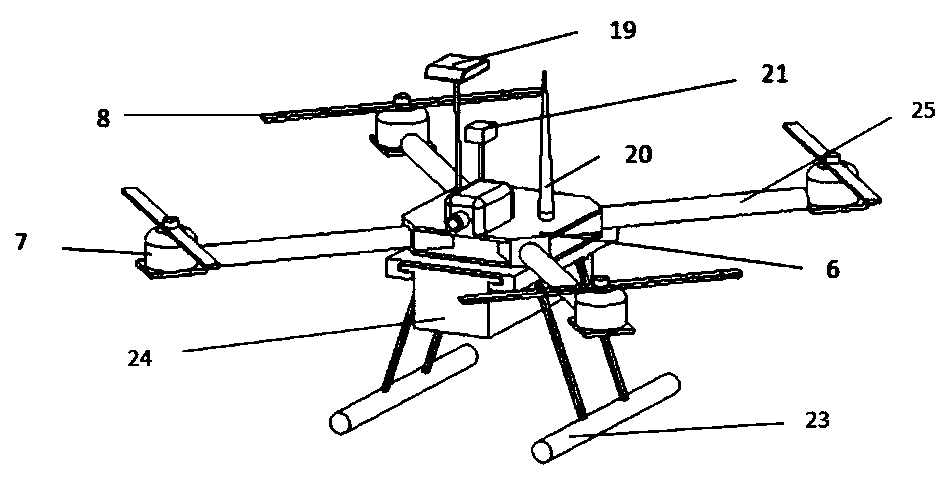

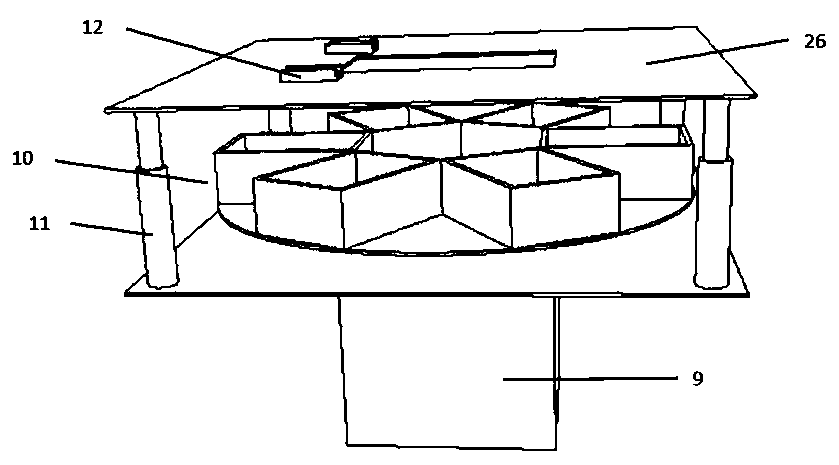

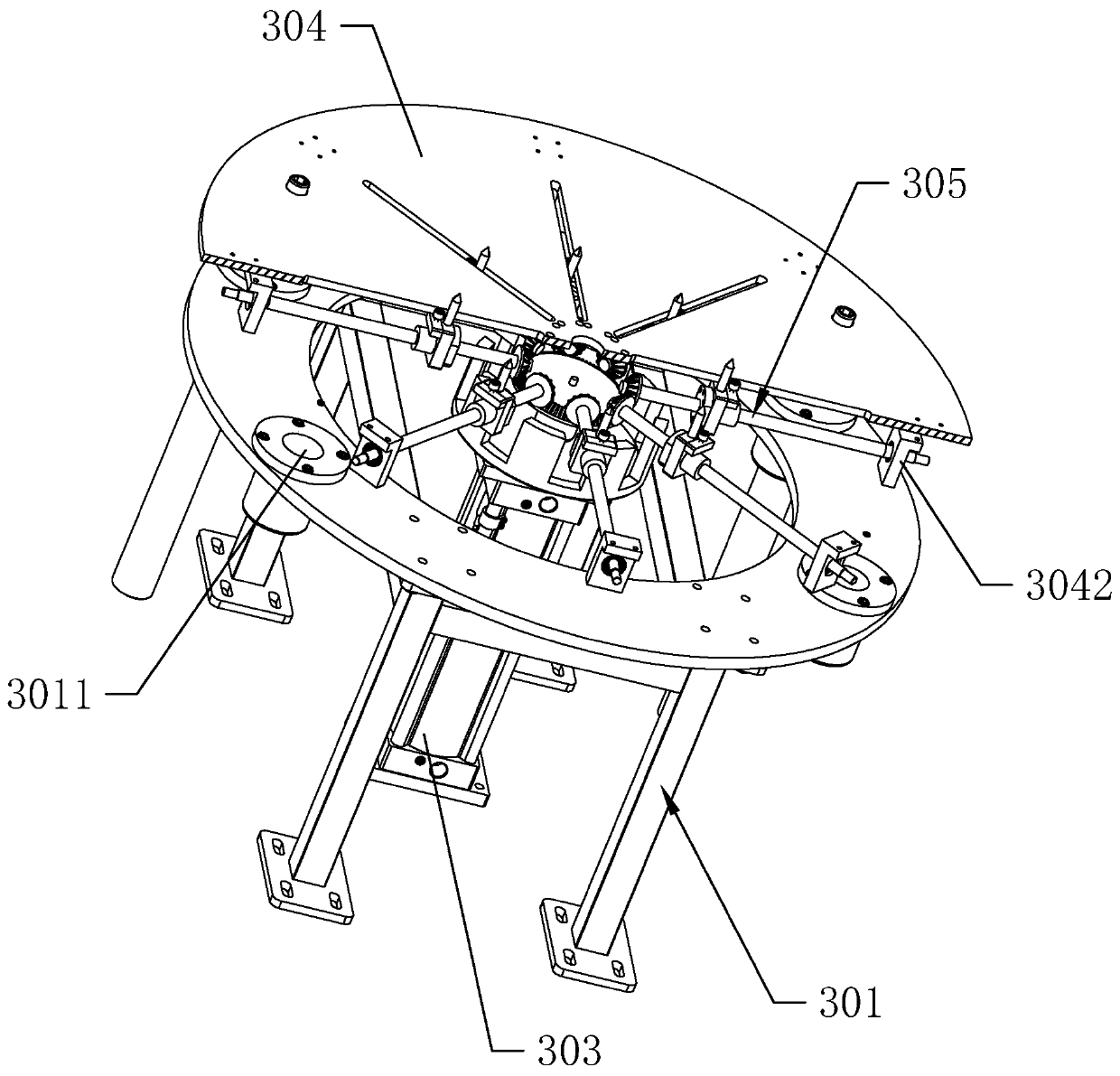

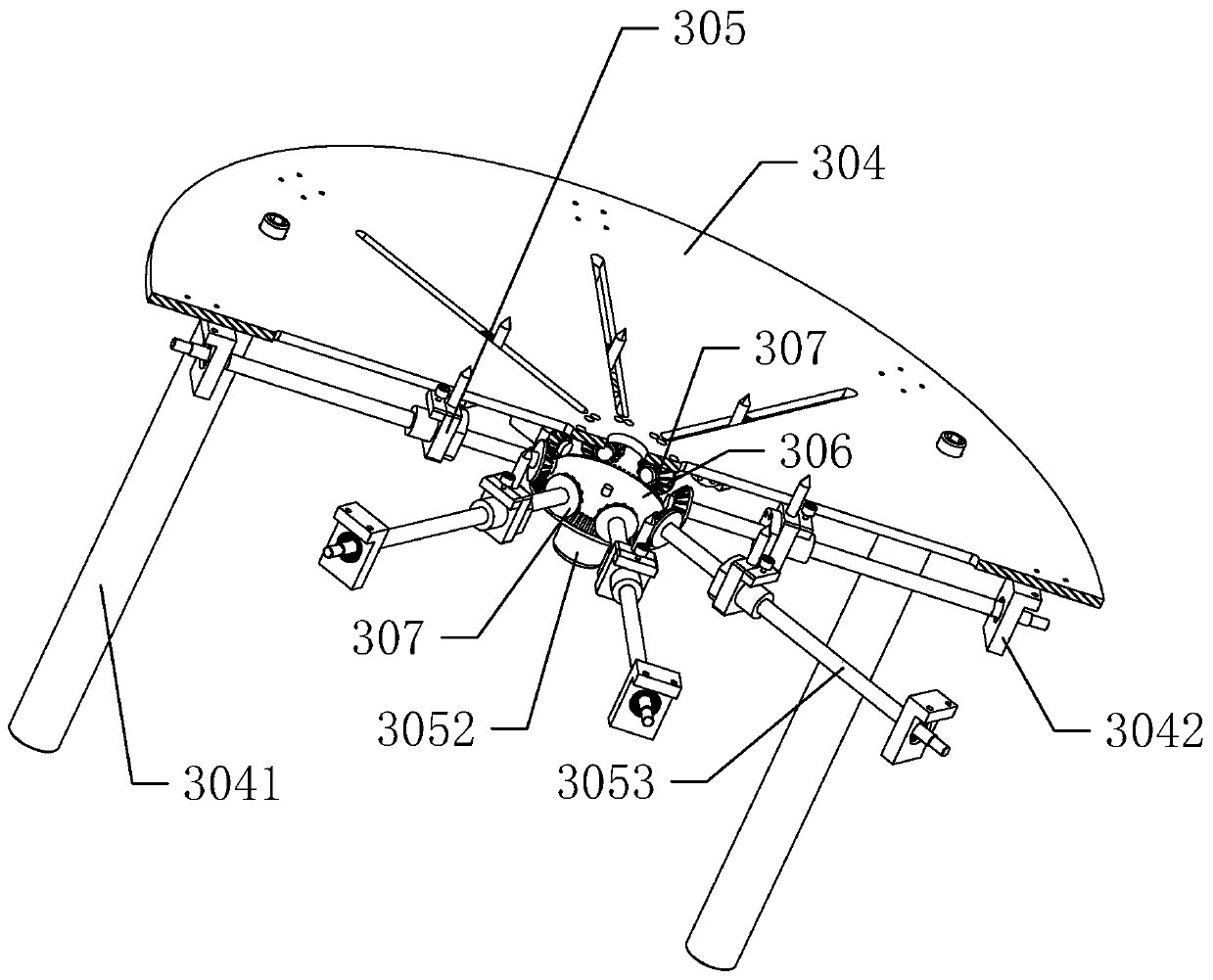

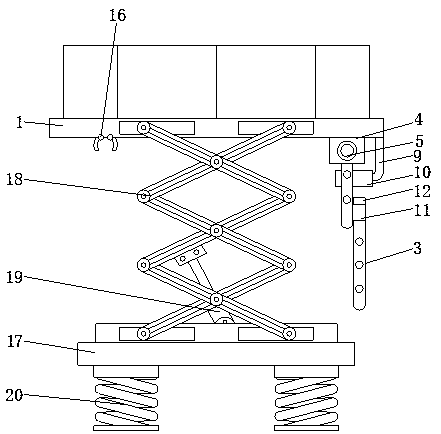

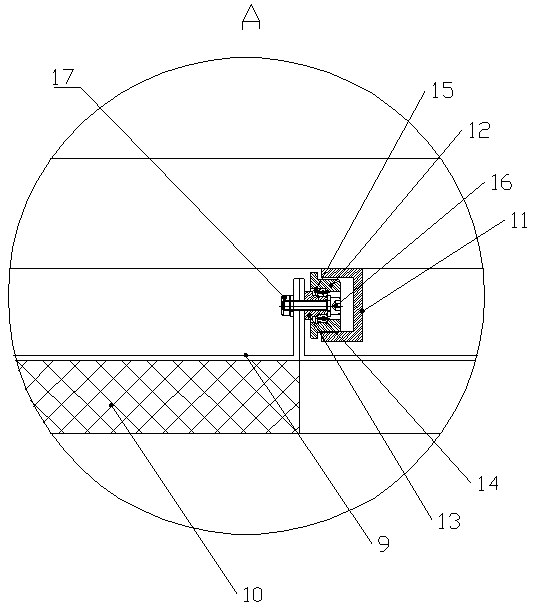

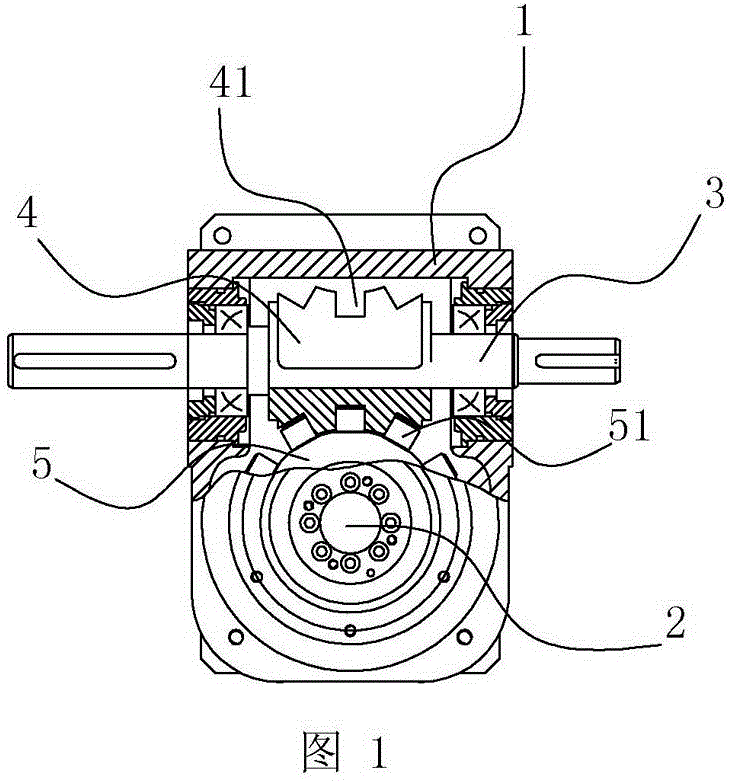

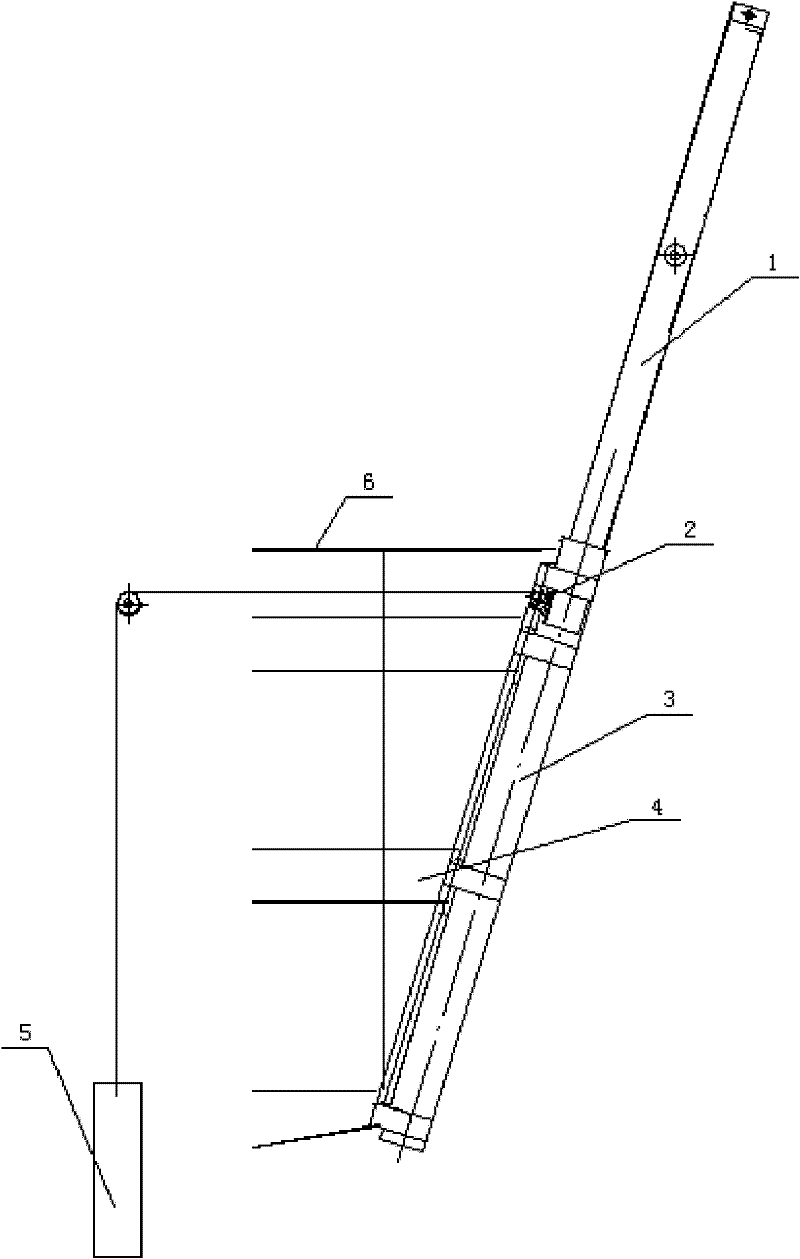

Maritime patrol equipment of unmanned aerial vehicle carried on unmanned ship and use method thereof

PendingCN110104139AReduce shakingUp and down stableLife-raftsAir-sea rescue devicesMarine engineeringCurrent point

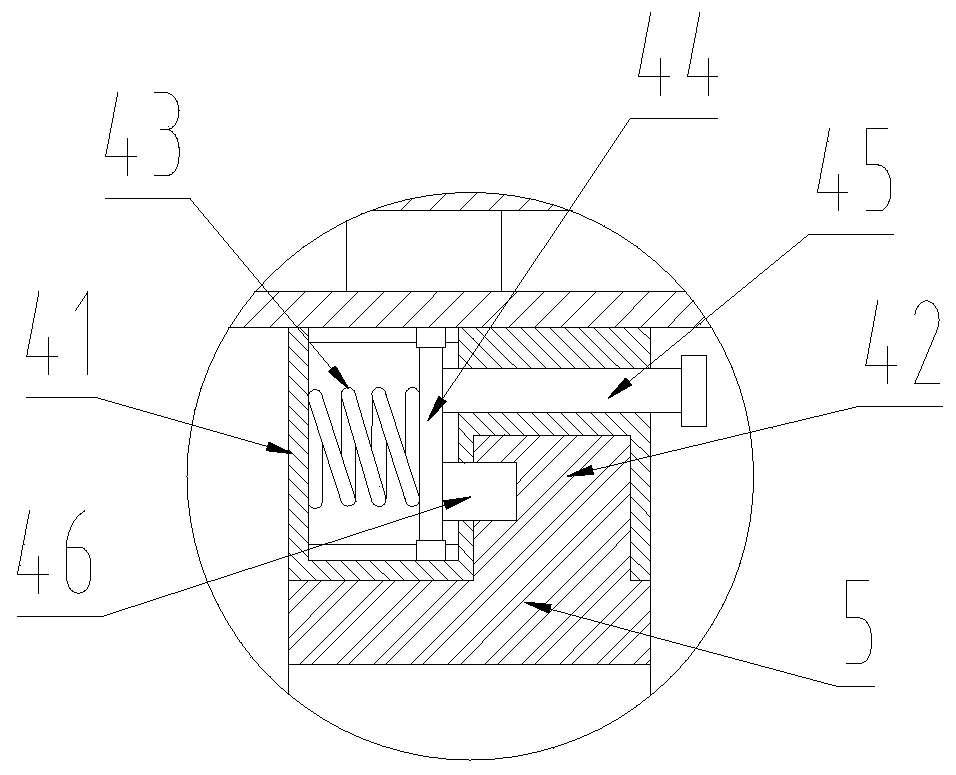

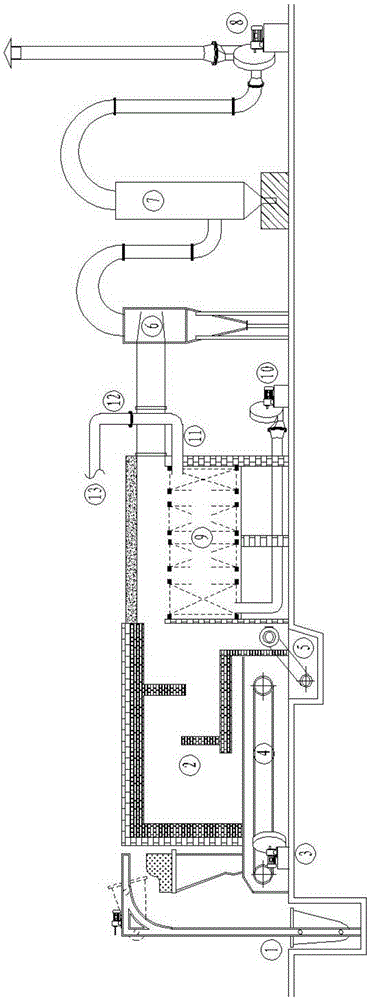

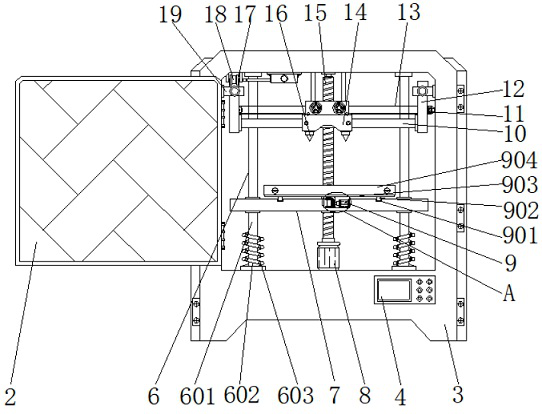

The invention discloses maritime patrol equipment of an unmanned aerial vehicle carried on an unmanned ship and a use method thereof. The maritime patrol equipment of the unmanned aerial vehicle carried on the unmanned ship comprises the unmanned ship, the unmanned aerial vehicle, an unmanned aerial vehicle take-off and landing platform system and an unmanned aerial vehicle battery automatic changing charging system. The use method of the maritime patrol equipment of the unmanned aerial vehicle carried on the unmanned ship comprises the following steps that a, the unmanned ship sails along a planning trajectory; b, the unmanned ship runs to a working area, and the unmanned aerial vehicle lifts off to work; c, the unmanned aerial vehicle transmits images and unmanned aerial vehicle relatedinformation to a ground station system; d, when the power capacity of the unmanned aerial vehicle is not enough, the unmanned aerial vehicle makes a return voyage after marking position information ofa current point; e, the unmanned aerial vehicle lands; f, a battery is changed; g, the battery is charged; h, a fully charged battery is mounted; i, the unmanned aerial vehicle returns to a marking position and returns after finishing working; and j, the unmanned ship continues to patrol. According to the maritime patrol equipment of the unmanned aerial vehicle carried on the unmanned ship, a shaking problem of the unmanned ship is solved so that the taking-off and landing of the unmanned aerial vehicle are stable; the safety of the whole system is guaranteed; and the cruising ability of theunmanned ship and the cruising ability of the unmanned aerial vehicle are improved.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

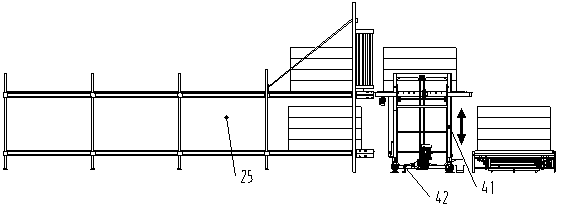

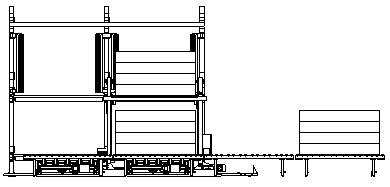

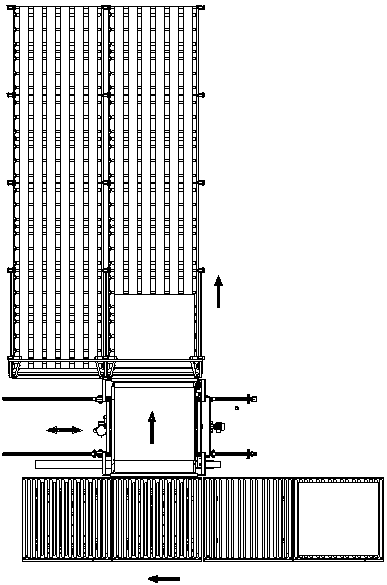

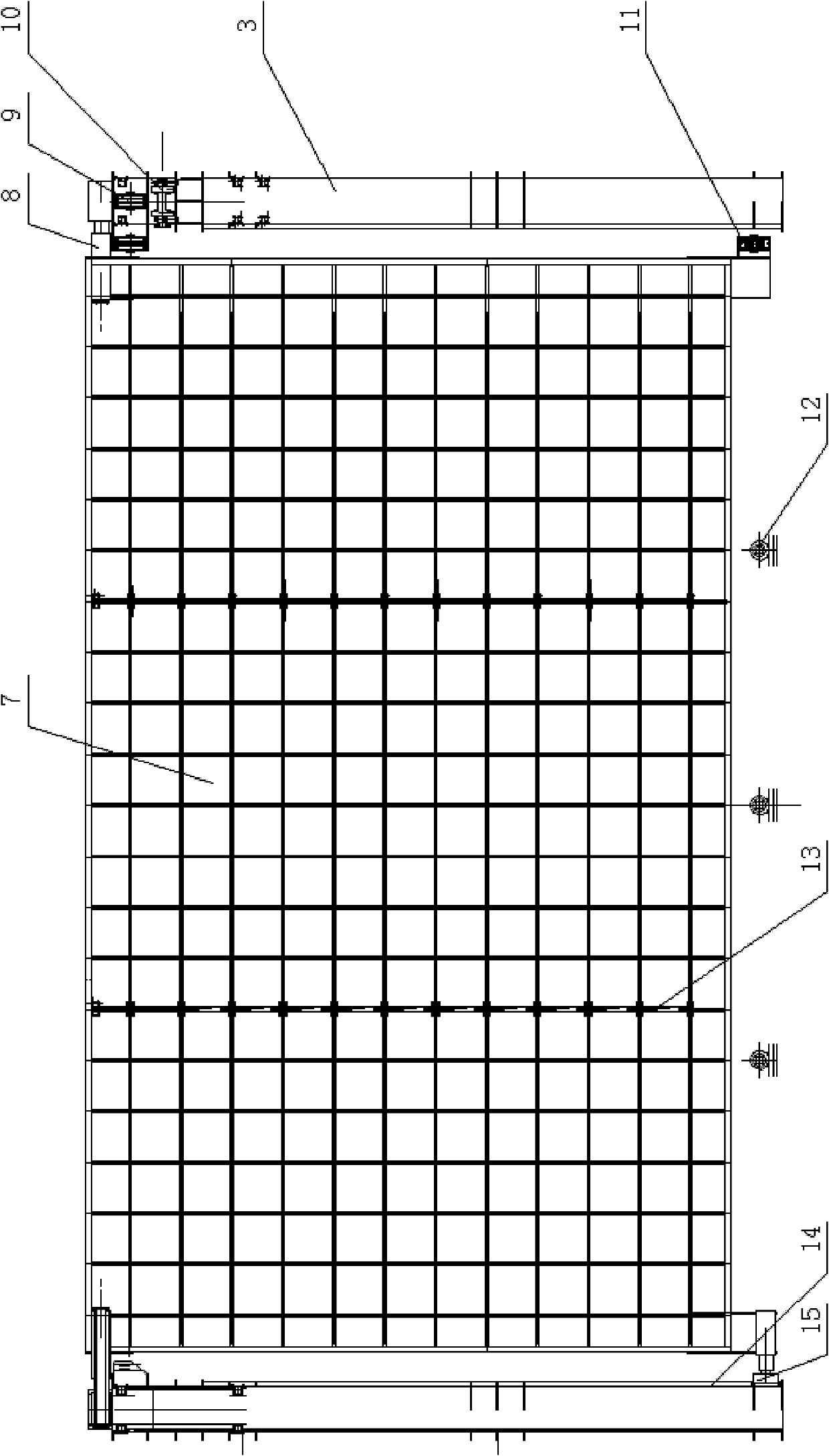

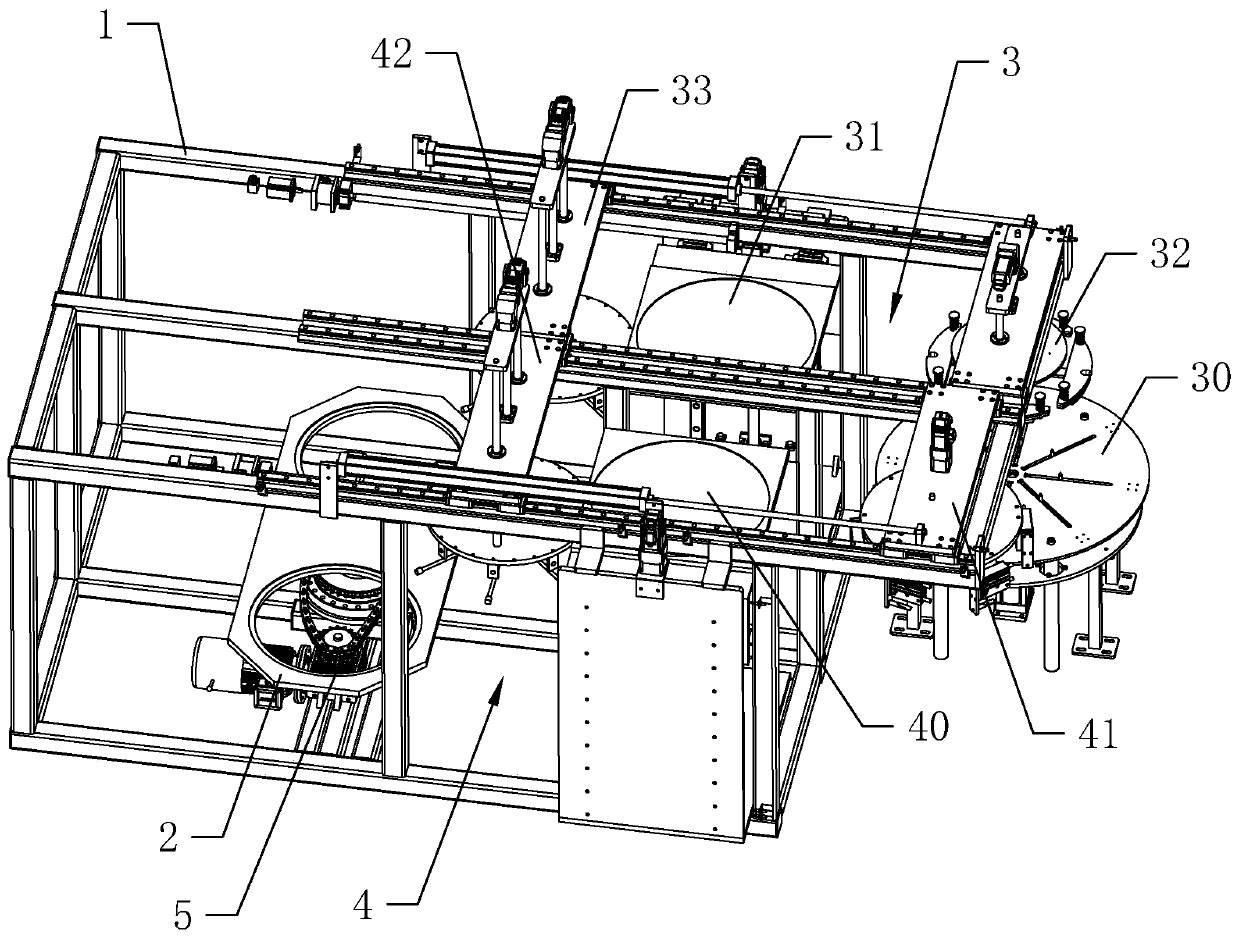

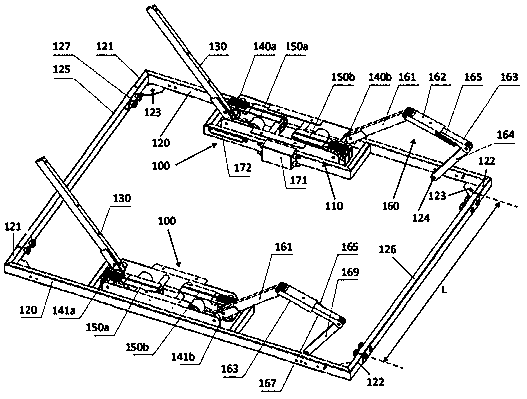

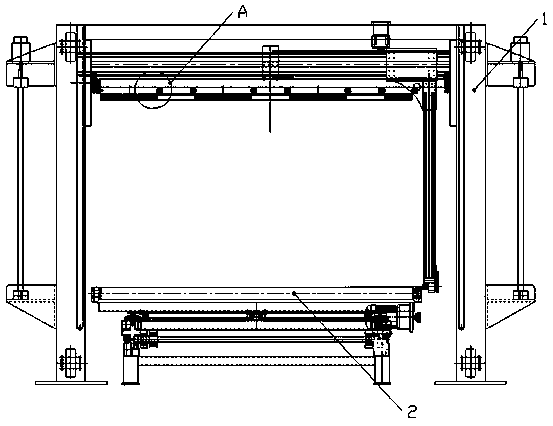

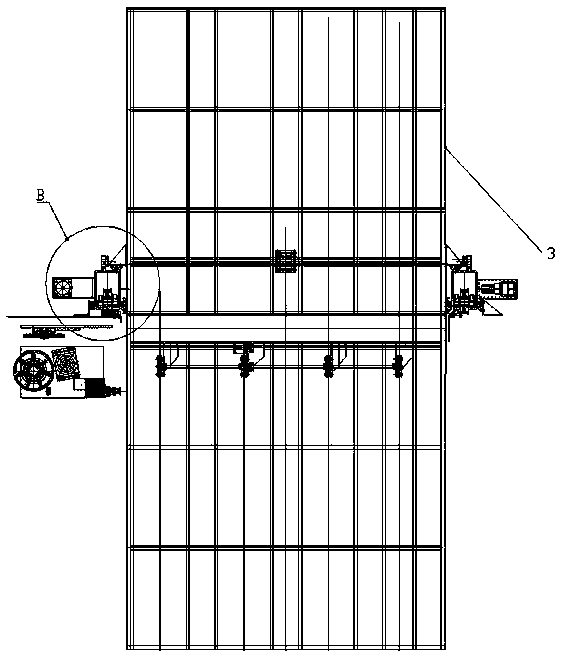

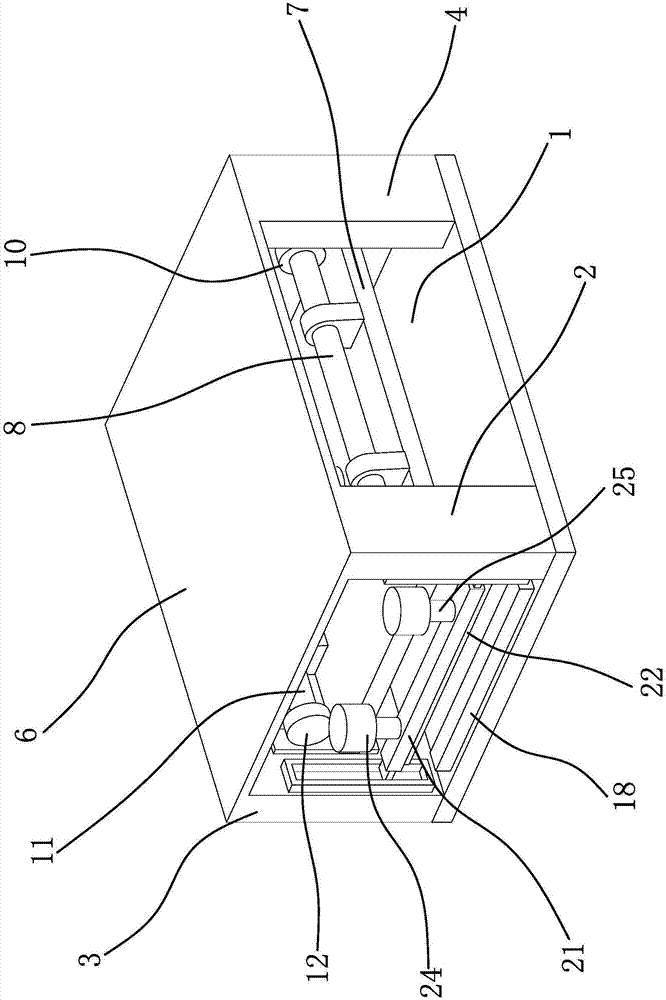

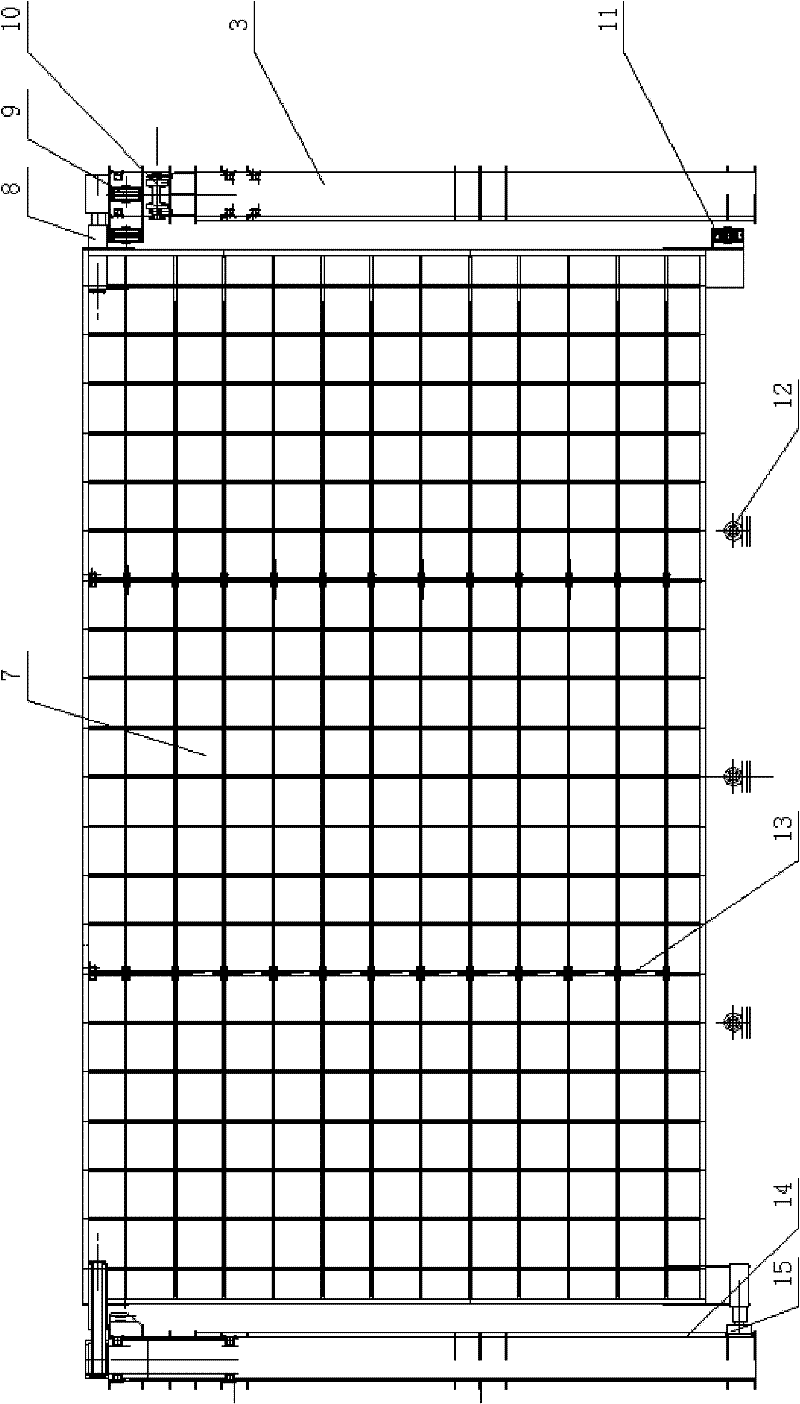

Automatic storage production line for mattress

PendingCN110758969ASmall footprintReduce manual laborConveyorsControl devices for conveyorsProduction lineEngineering

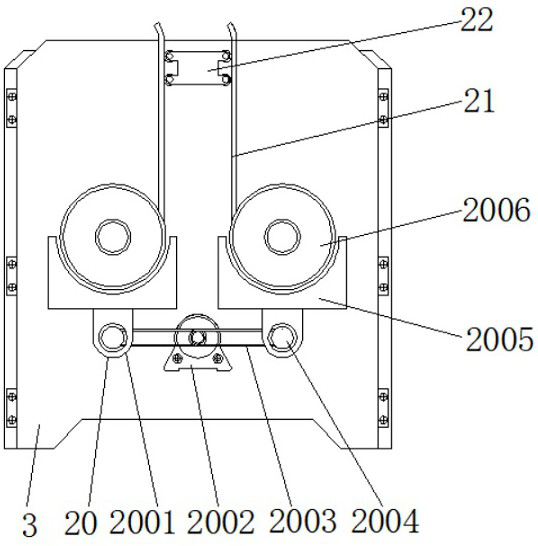

The invention relates to an automatic storage production line for a mattress. The automatic storage production line for the mattress comprises a conveying assembly, a storage bracket, a transfer assembly, a reversing conveying assembly, wherein the storage bracket is provided with a plurality of sub-spaces for accommodating mattress storage, the transfer assembly comprises a transfer bracket, thetransfer bracket is driven by a horizontal moving mechanism to move back and forth in the conveying direction of the mattress, the transfer bracket is provided with a transfer conveying bracket, the transfer conveying bracket is driven by a lifting mechanism to lift up and down, and the reversing conveying assembly is arranged at a discharge port of the conveying bracket. The automatic storage production line for the mattress has the advantages that through the mutual matching among the conveying assembly, a storage assembly, the transfer assembly and the reversing conveying assembly, the mattress conveyed on the conveying assembly is automatically transferred to the storage assembly to be stored, the manual operation is not needed, the manual labor is greatly reduced, the space required to be used due to forklift transfer is avoided, and the occupied area of the whole production line is reduced.

Owner:南通恒康数控机械股份有限公司

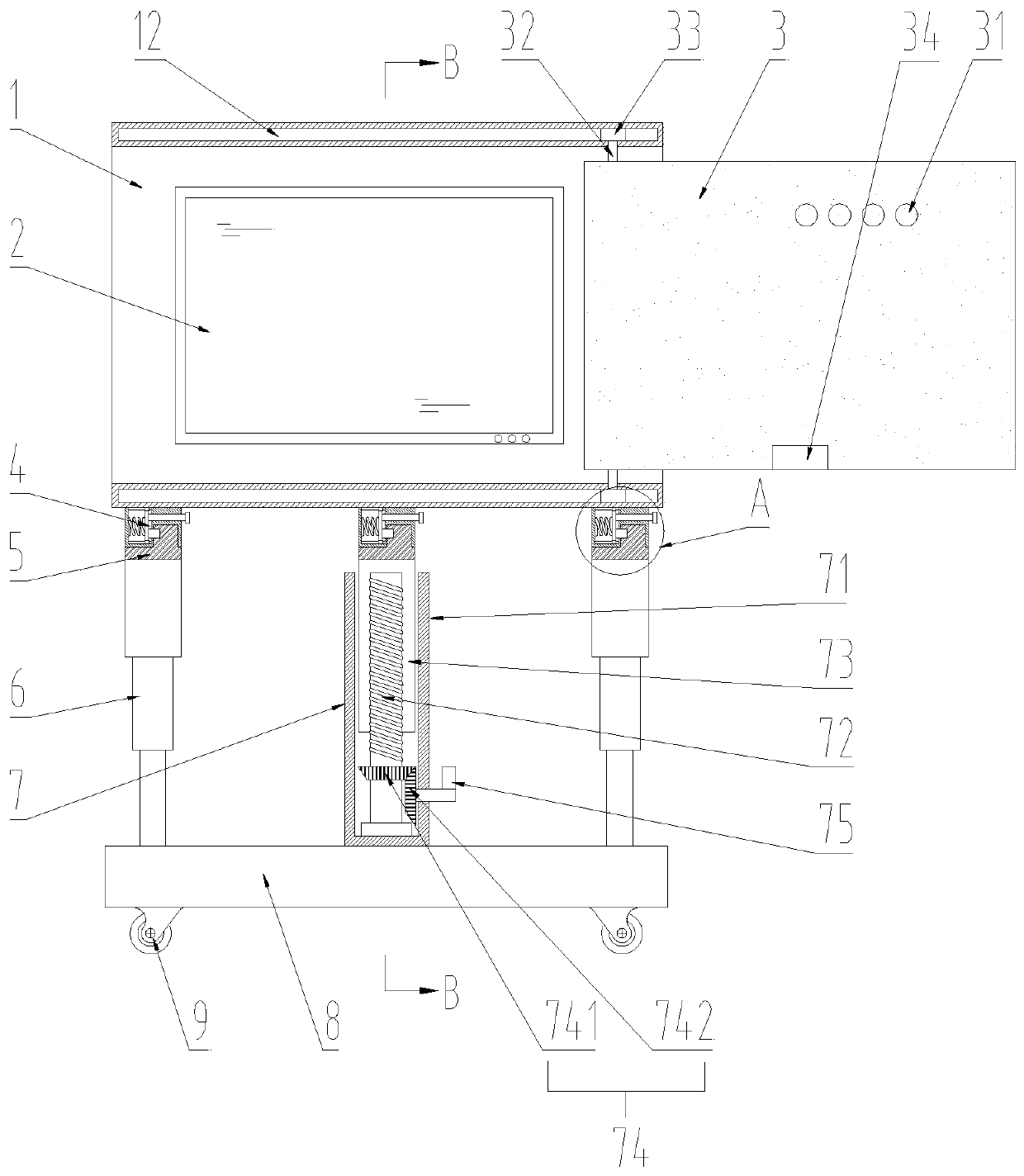

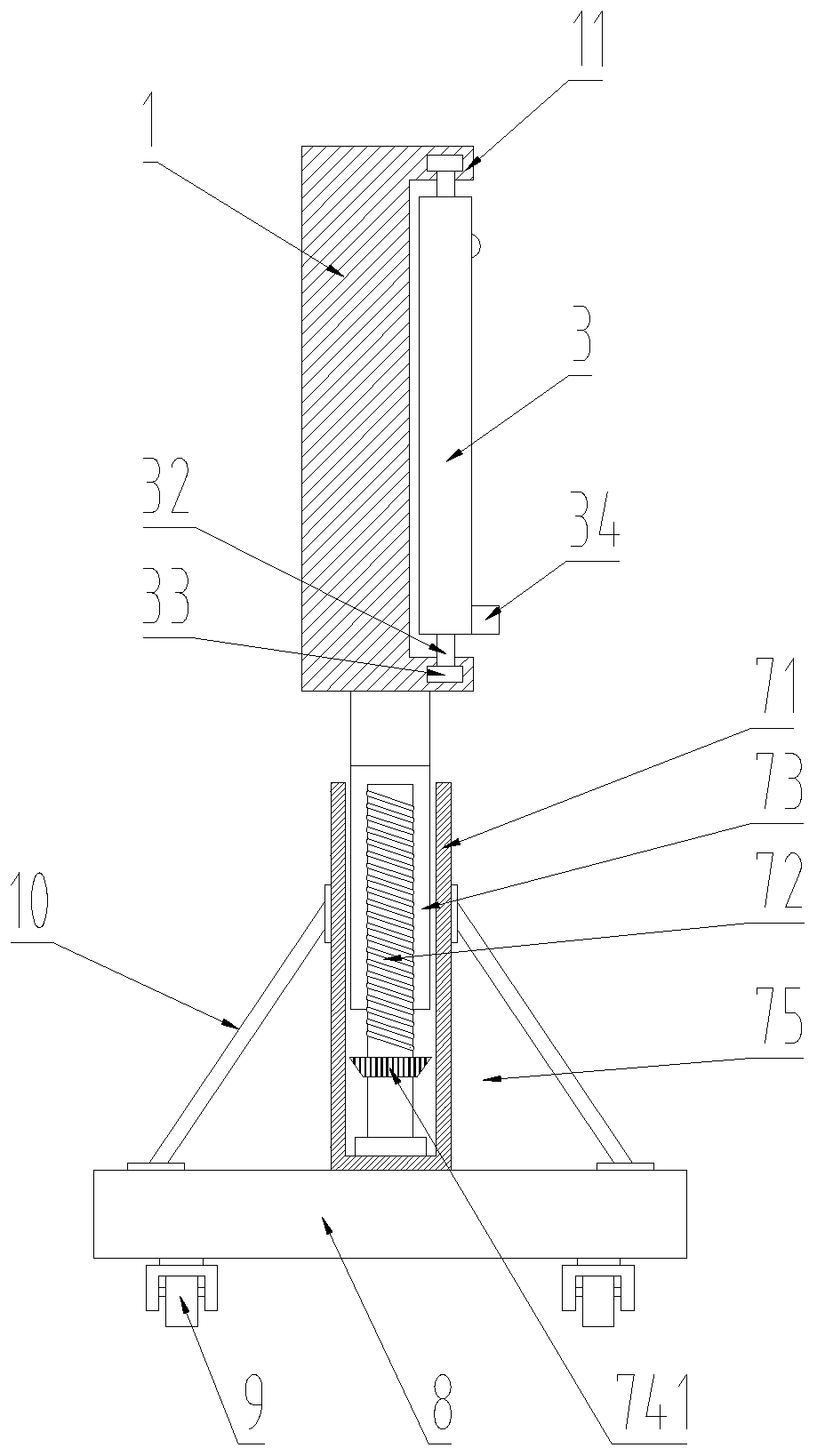

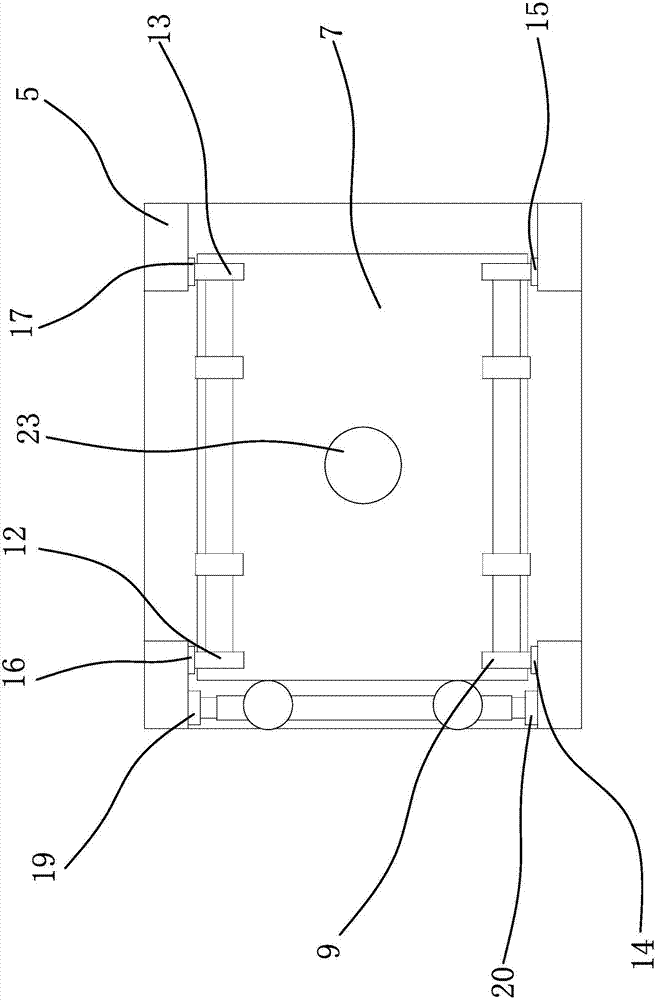

Teaching auxiliary device

PendingCN110782712ARich teaching contentImprove practicalityFurniture partsStands/trestlesMechanical engineeringElectrical and Electronics engineering

The invention discloses a teaching auxiliary device. The teaching auxiliary device comprises a carrier plate, a base and a moving wheel; the teaching auxiliary device further comprises a magnetic writing pad, a telescopic rod and a height adjusting mechanism; the front surface of the carrier board is slidably connected with the magnetic writing board that can move laterally along the front surfaceof the carrier plate; a magnet is arranged on the front surface of the magnetic writing board; a mounting mechanism is fixedly arranged at the bottom of the carrier plate; the mounting mechanism is detachably connected with a mounting block; the mounting block is arranged at the top of the telescopic rod and the height adjusting mechanism; and the bottoms of the telescopic rod and the height adjusting mechanism are fixed on the base. According to the teaching auxiliary device provided by the invention, video play and material display can be carried out synchronously, the practicability is strong, the installation and disassembly are convenient, carrying is facilitated, the height adjustment is convenient and the operation is simple.

Owner:SICHUAN TECH & BUSINESS UNIV

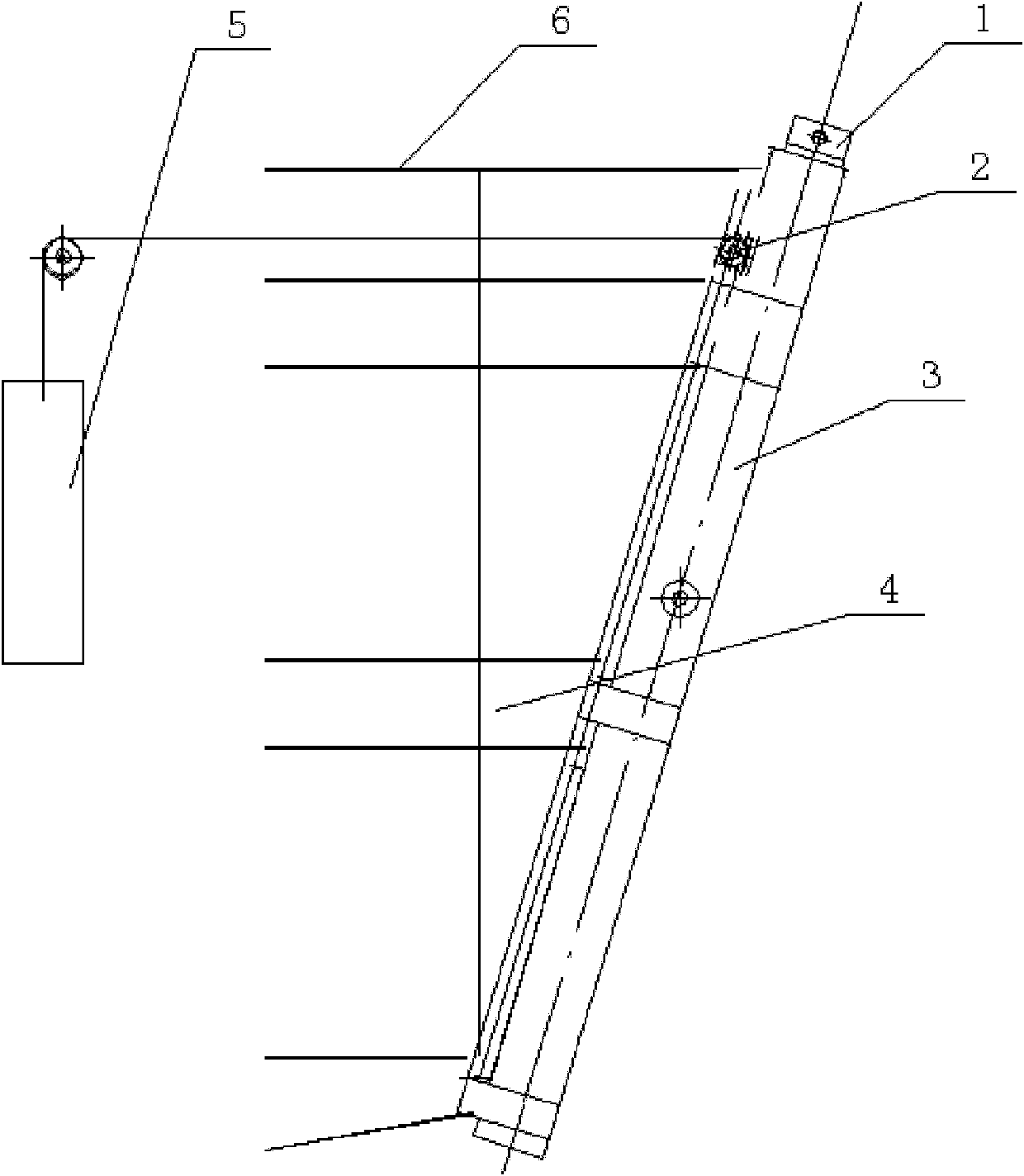

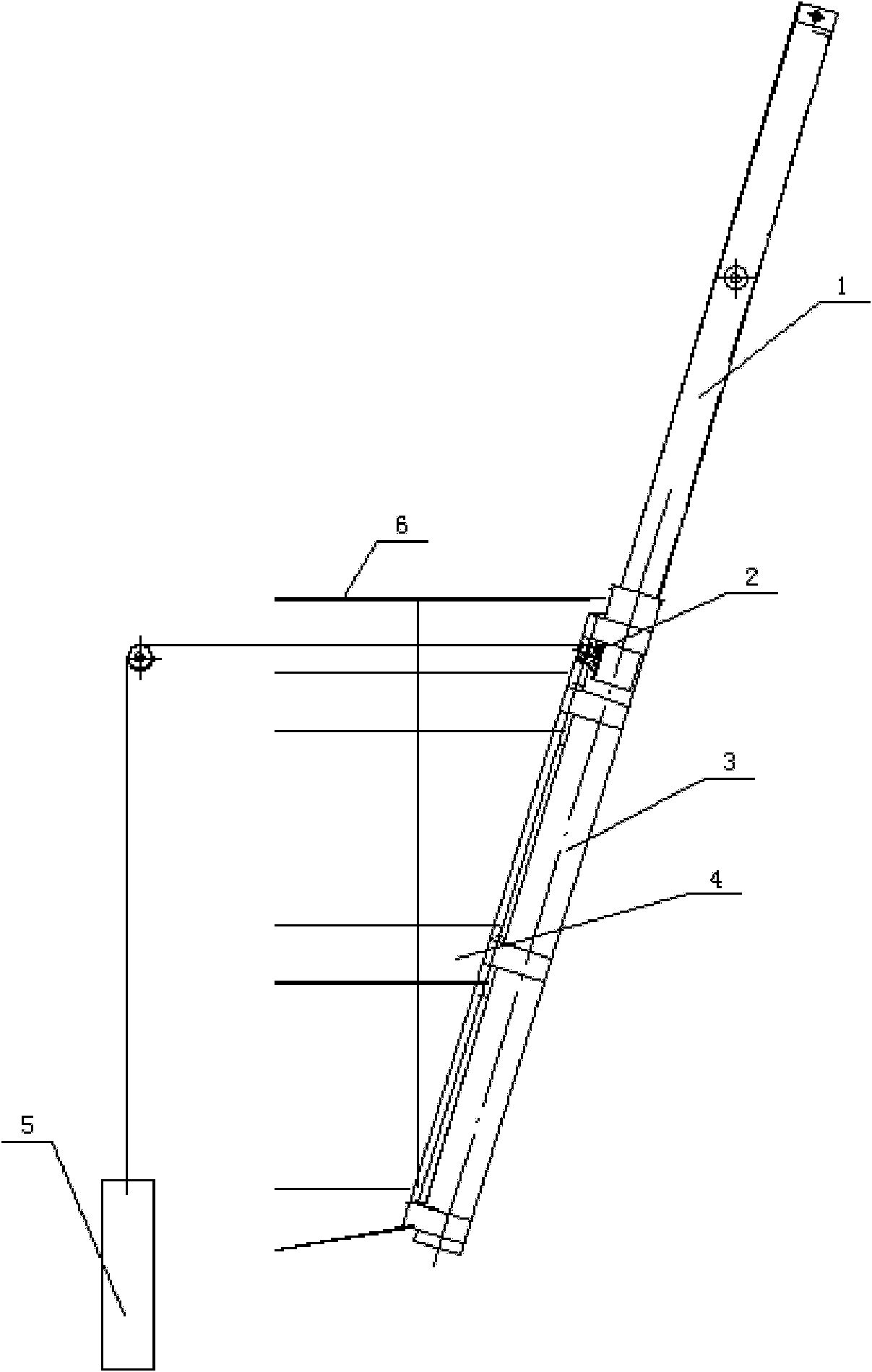

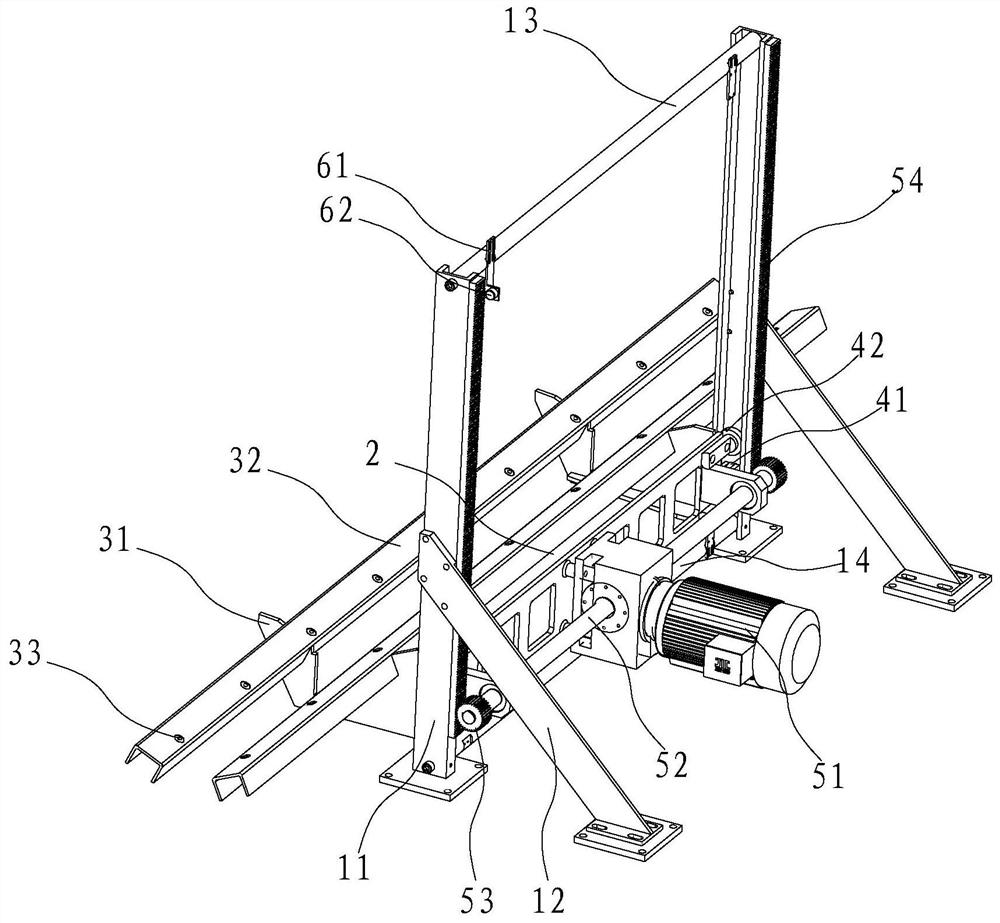

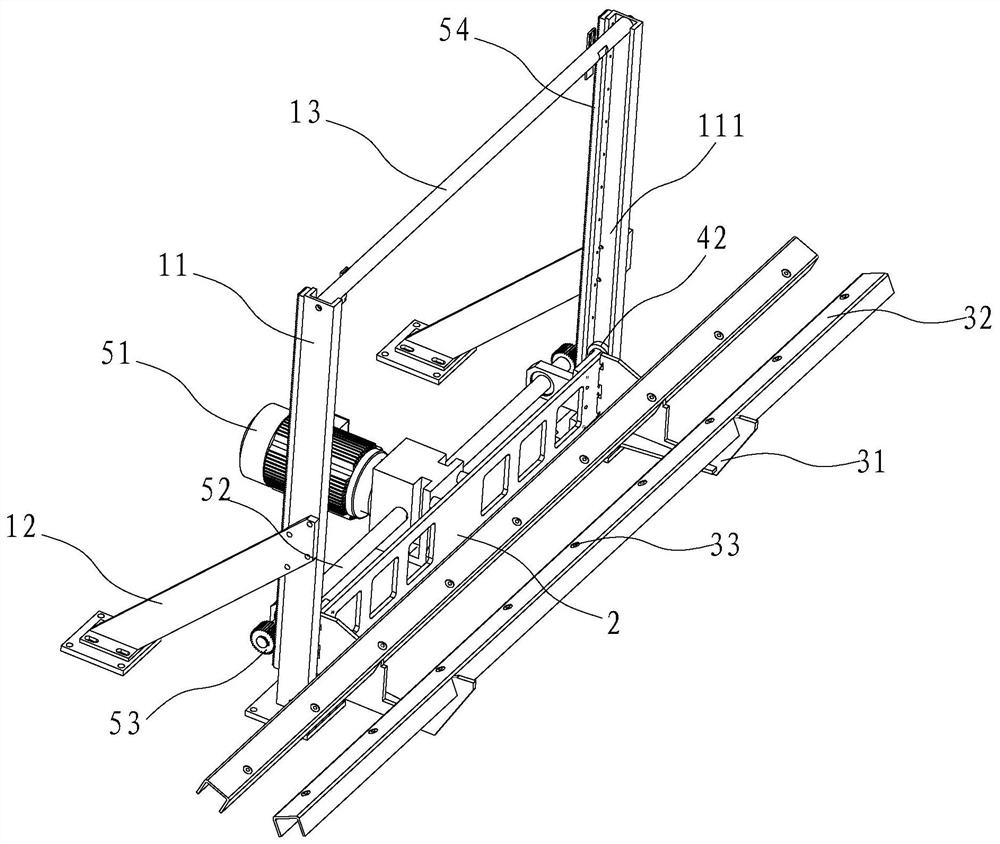

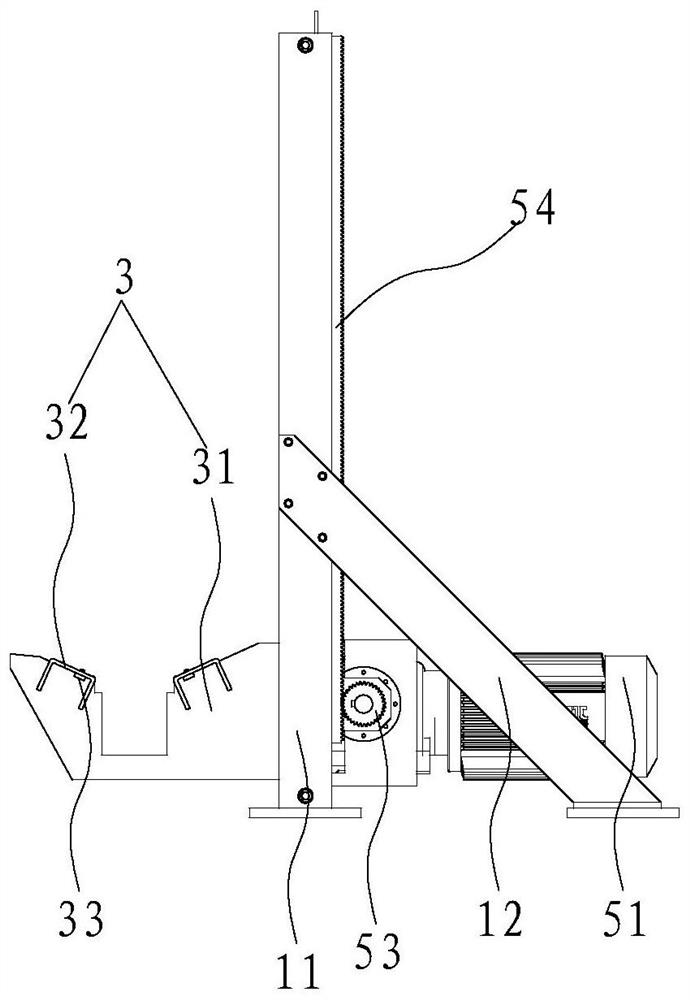

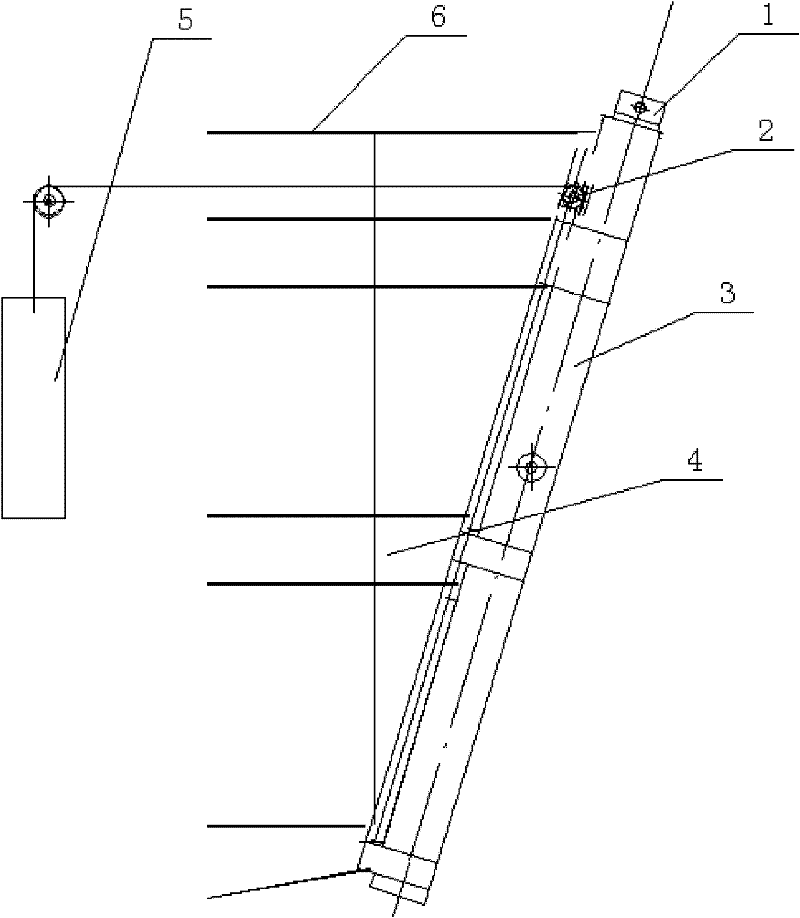

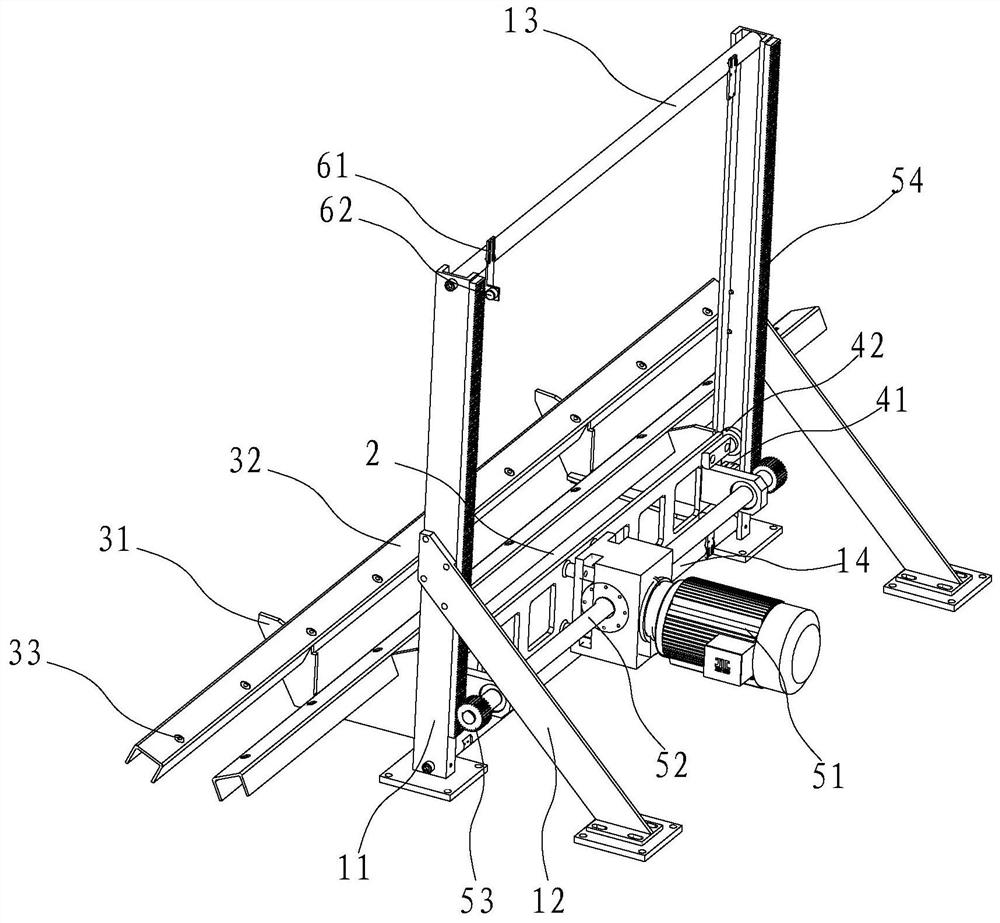

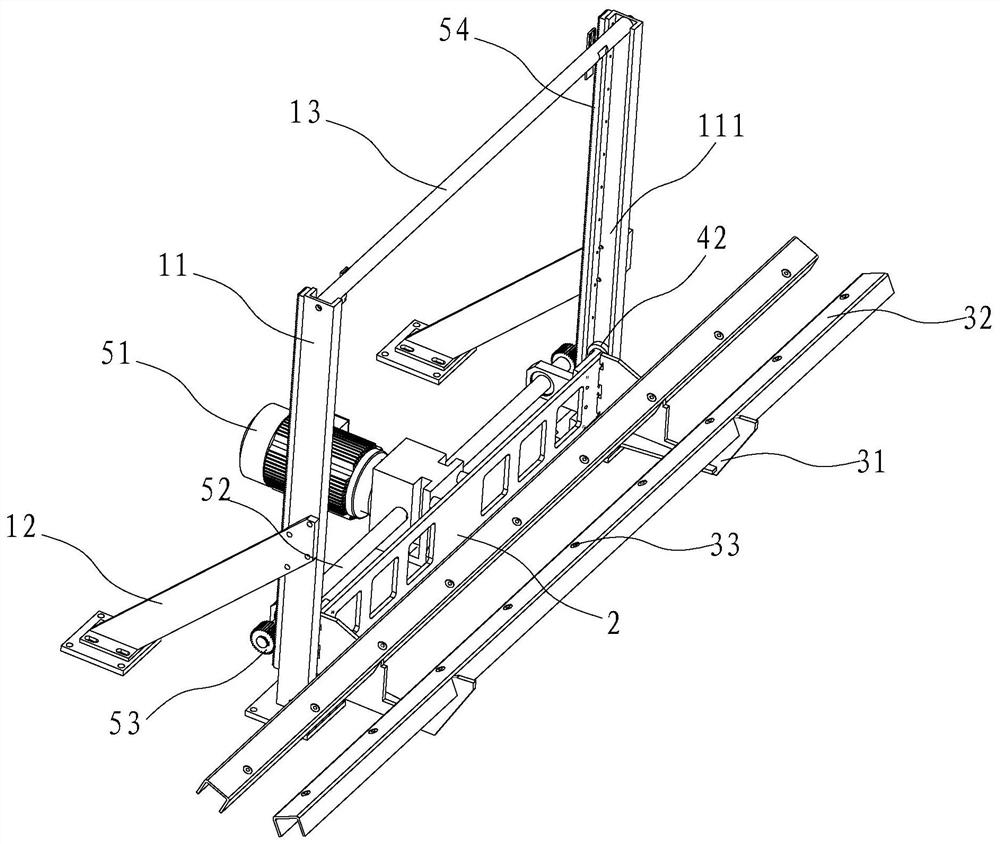

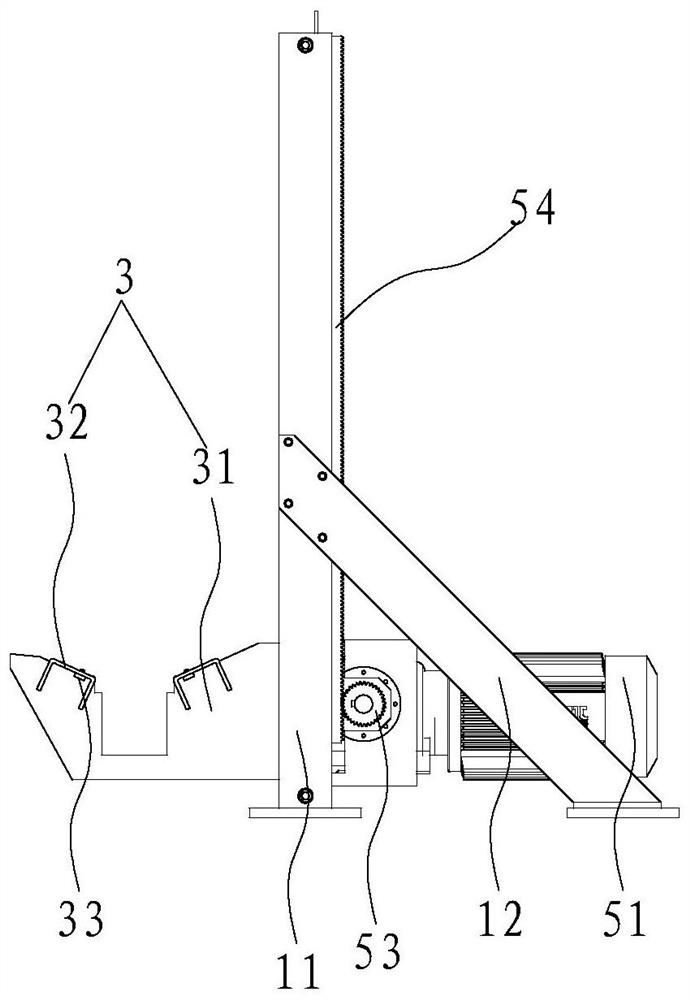

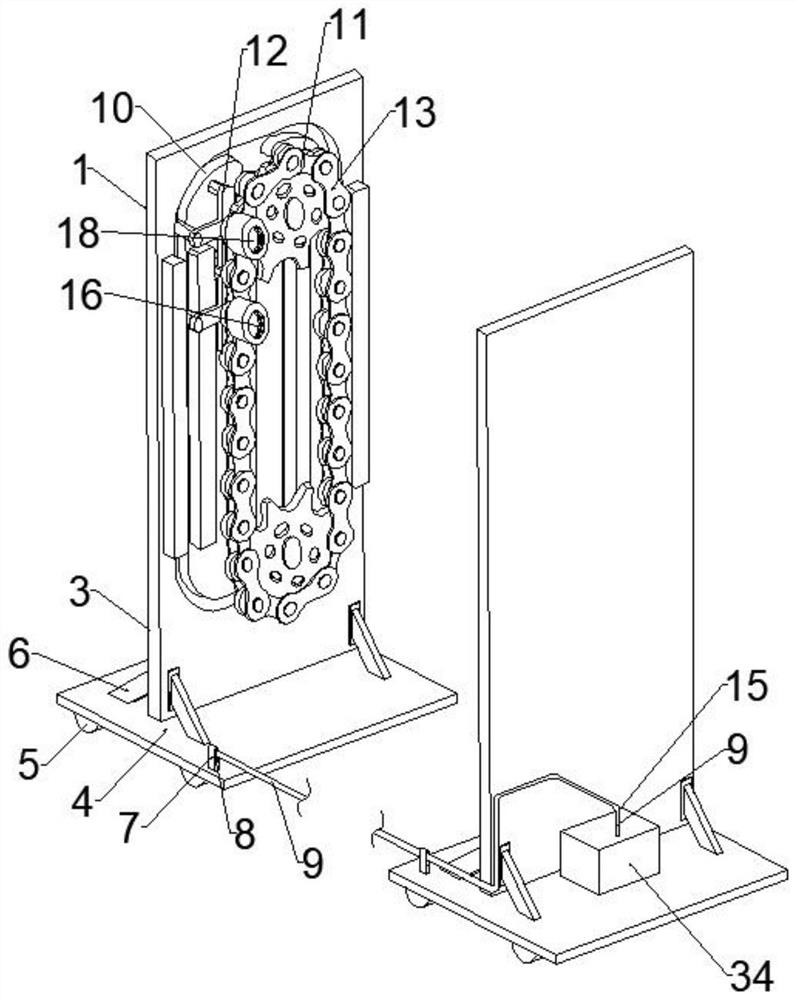

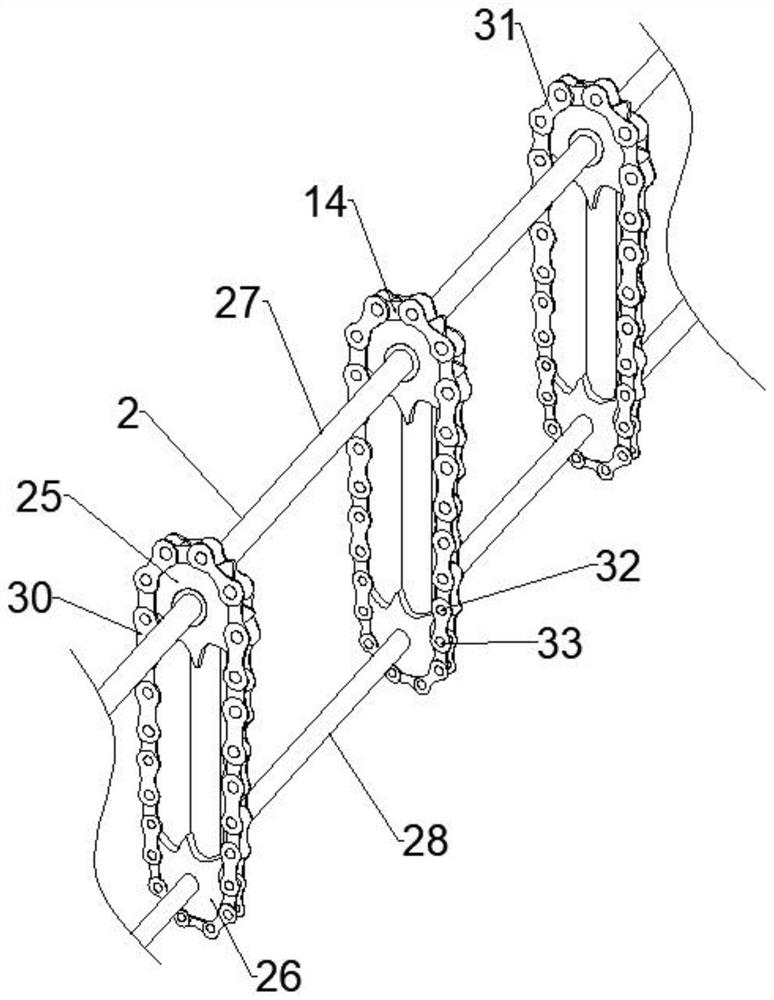

Large-scale lifting screen performance machine with long-span synchronous lifting arm

ActiveCN102168787ASmooth liftUp and down stableStands/trestlesIdentification meansFar distanceEngineering

The invention relates to a large-scale lifting screen performance machine with a long-span synchronous lifting arm, which is mainly formed by a lifting screen, fixed arms, telescopic arms, a driving mechanism, transmission mechanisms and a balance weight mechanism, wherein the tops of both sides of the lifting screen are fixed to the top ends of the two telescopic arms respectively; the two telescopic arms are arranged in the two fixed arms longitudinally in a lifting way; a middle driving mechanism which corresponds to the top ends of the fixed arms is fixedly arranged on a fixture in the rear of the lifting screen; the synchronous transmission mechanisms are arranged on both sides in the lateral direction of the driving mechanism; the driving mechanism drives the telescopic arms to drive the lifting screen to lift by the transmission mechanisms; and the balance weight mechanism are connected to the bottom ends of the two telescopic arms and the lifting screen commonly. The large-scale lifting screen performance machine has scientific and reasonable structural design, runs stably and is safe and reliable and the design desire of the extra large-scale outdoor lifting screen is realized, so that audiences can enjoy the spectacular scene of lifting large-scale light-emitting diode (LED) display frames slowly at a far distance.

Owner:马超

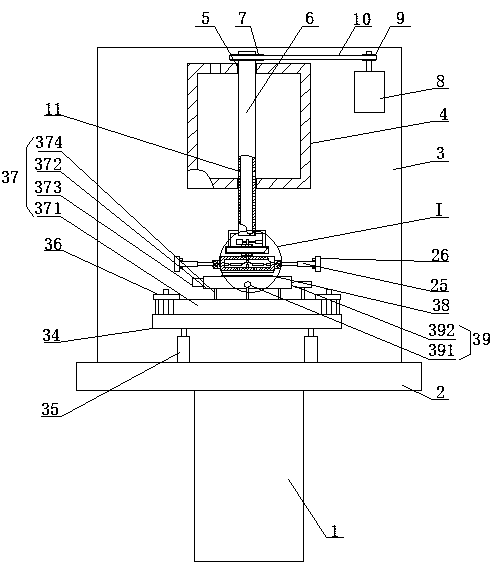

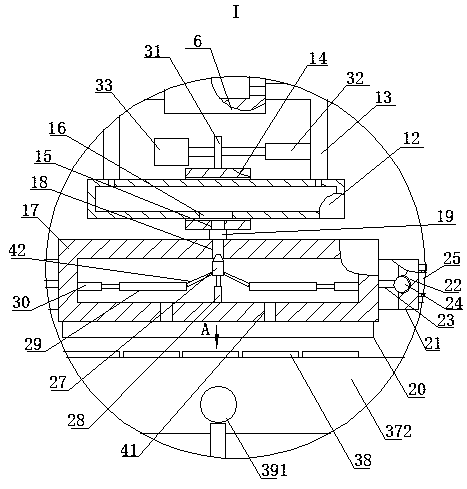

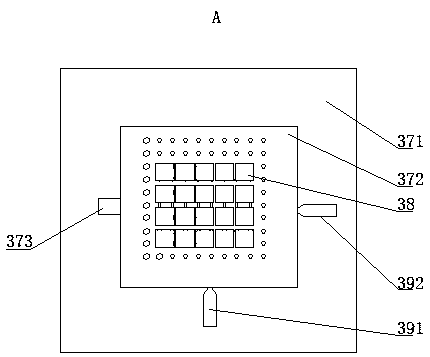

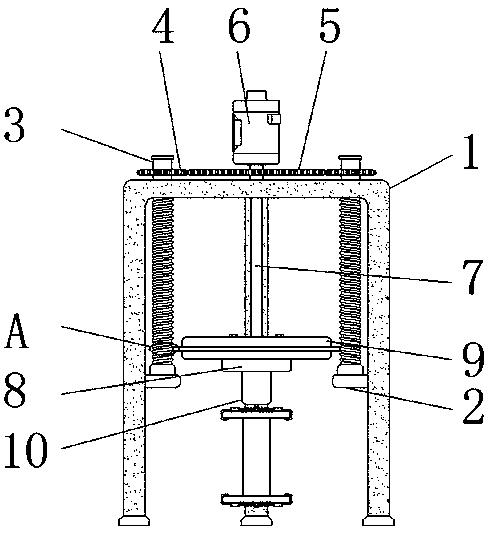

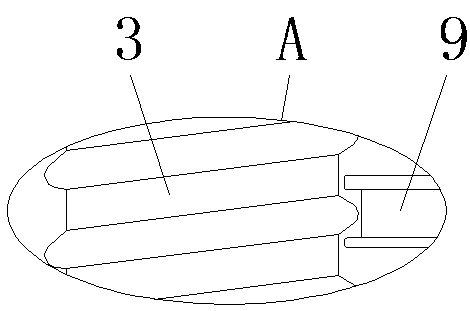

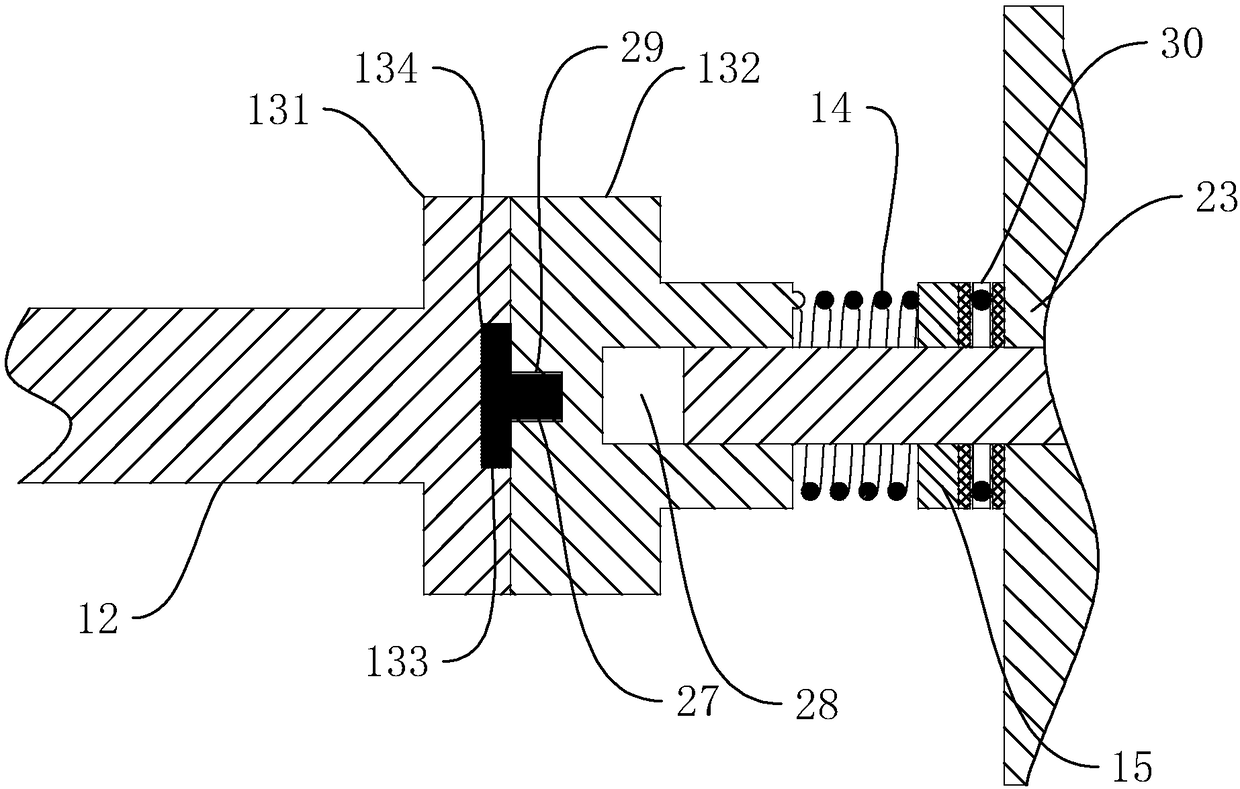

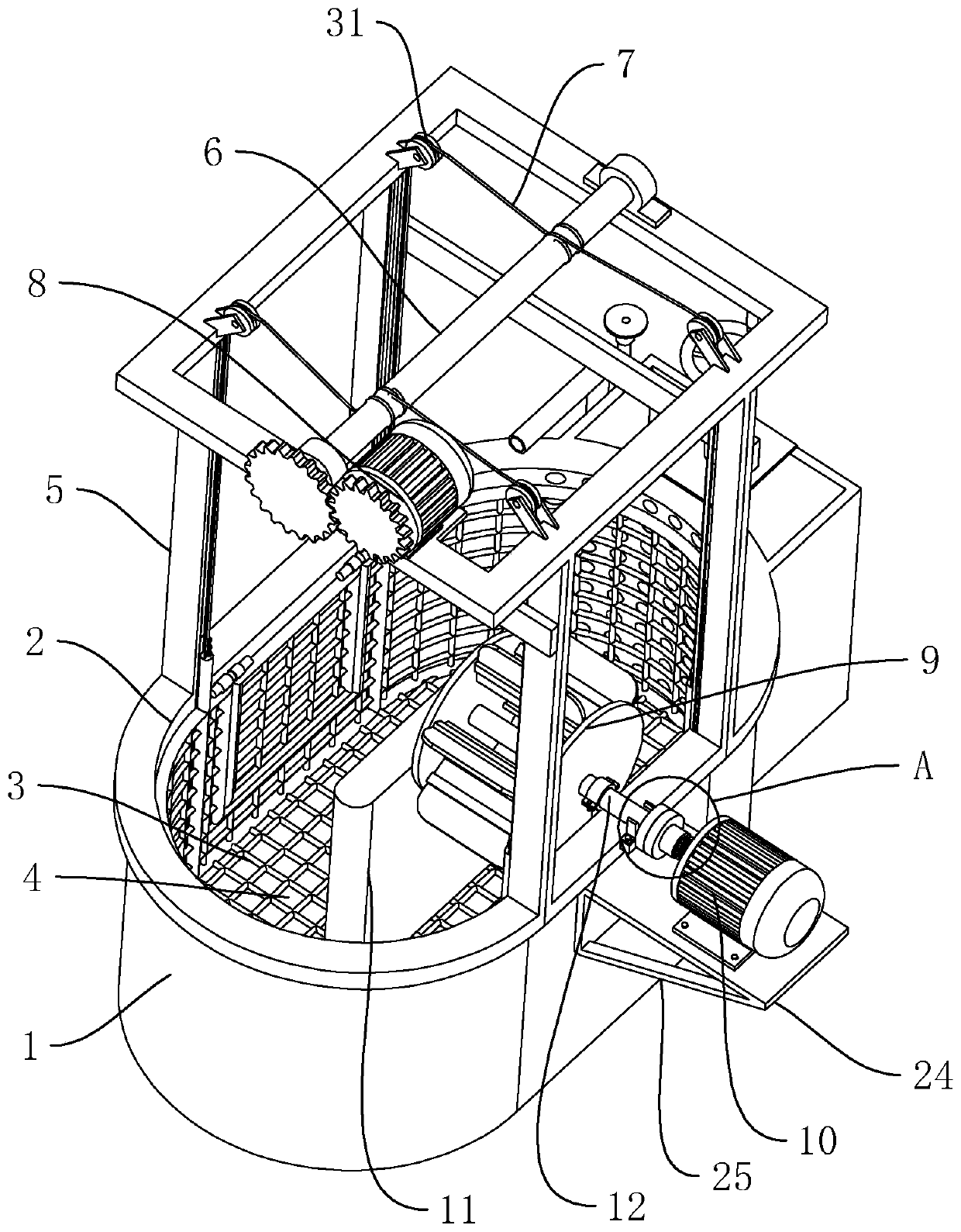

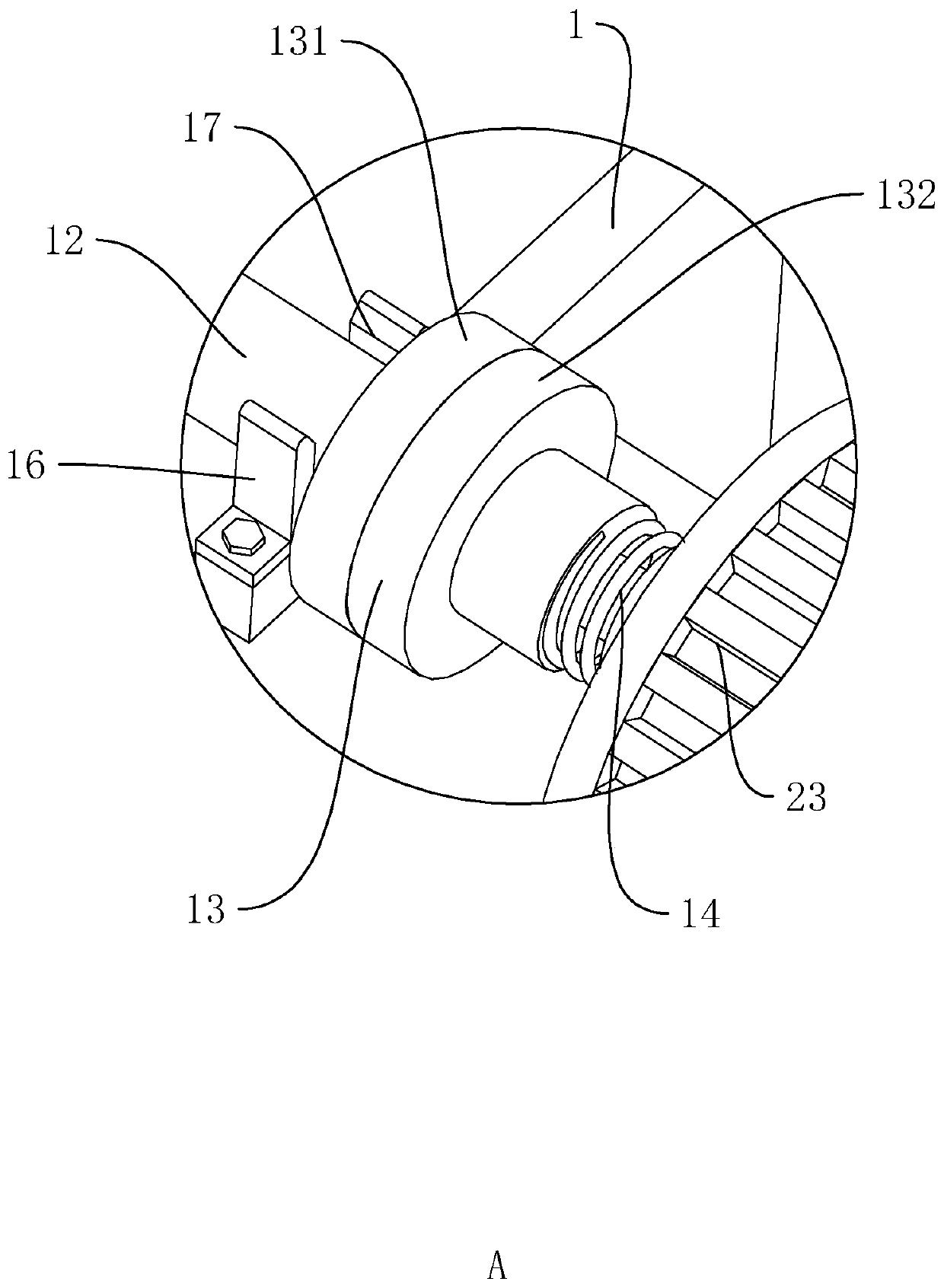

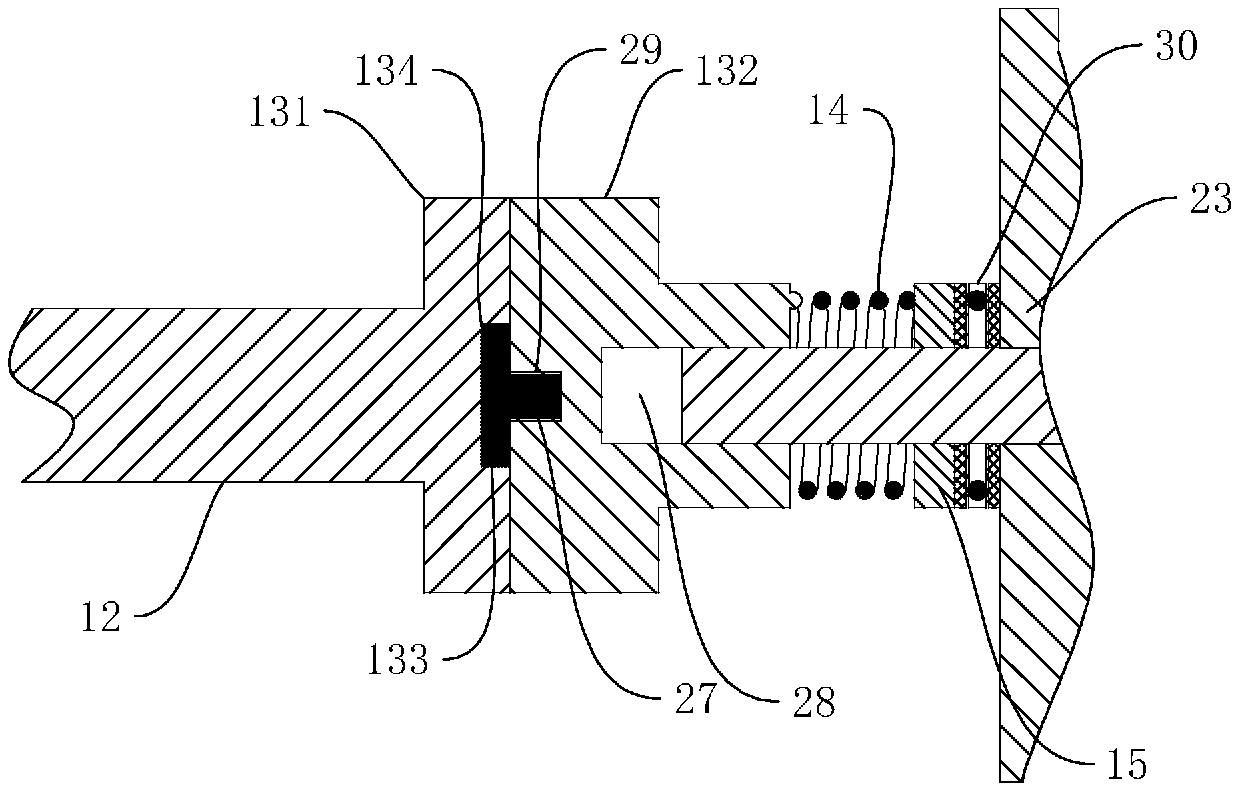

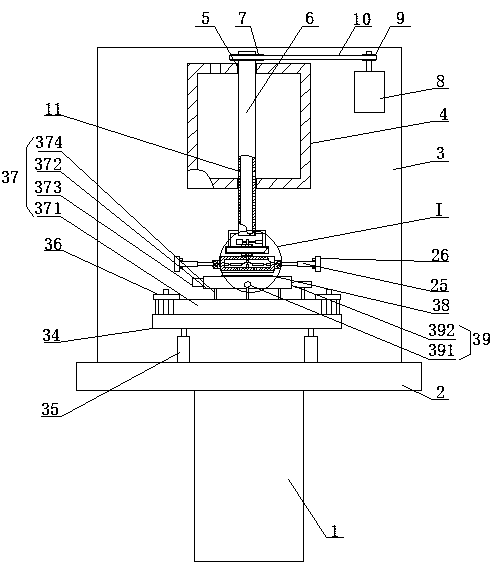

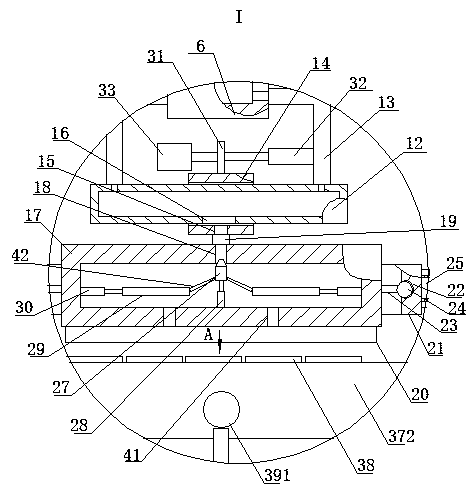

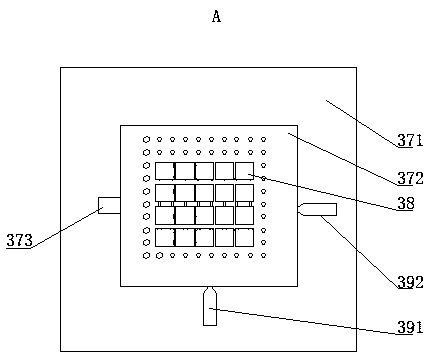

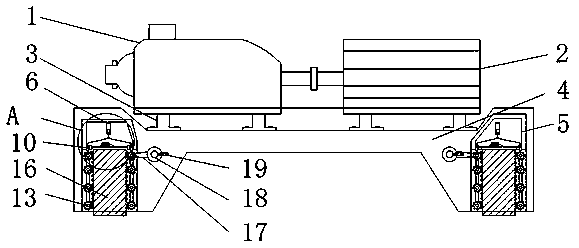

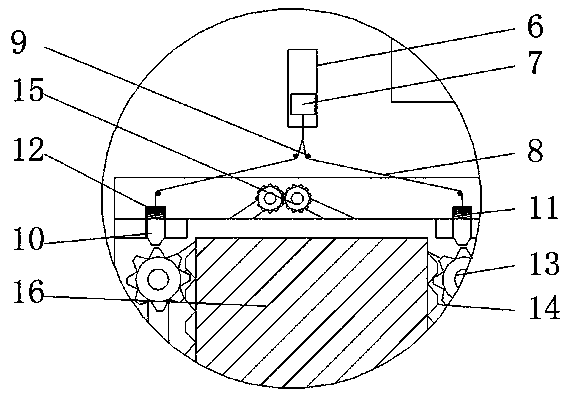

Machining device for ultrasonic grinding of sapphire lens

InactiveCN108381376AHigh precisionImprove grinding efficiencyOptical surface grinding machinesGrinding drivesUltrasonic vibrationEngineering

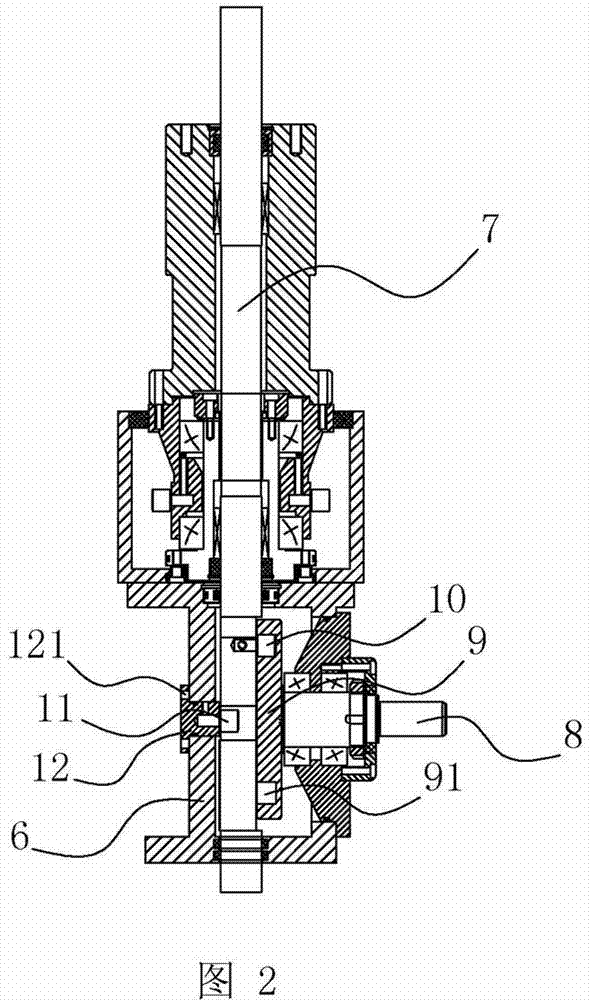

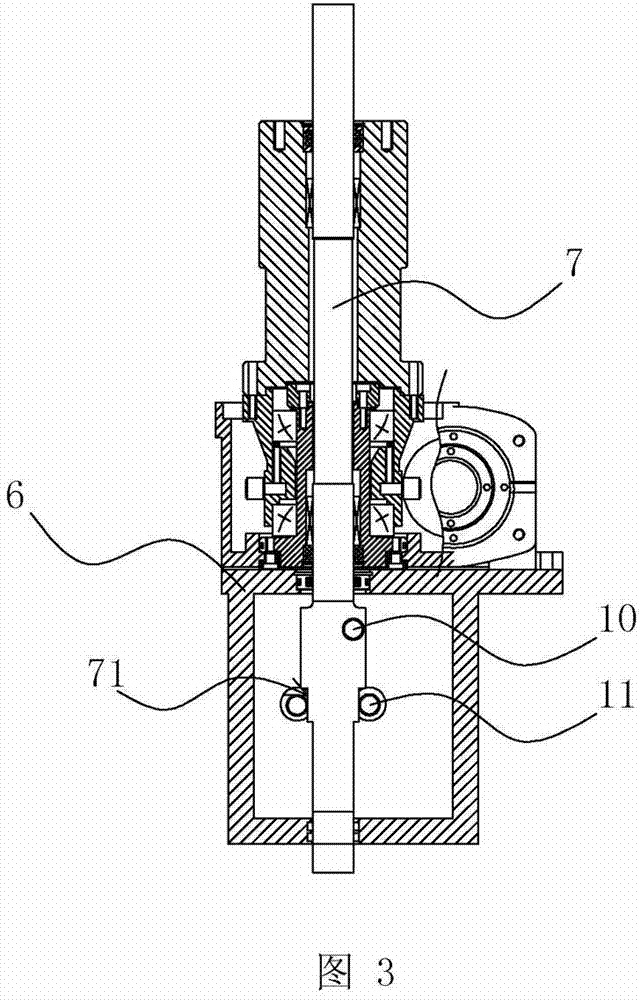

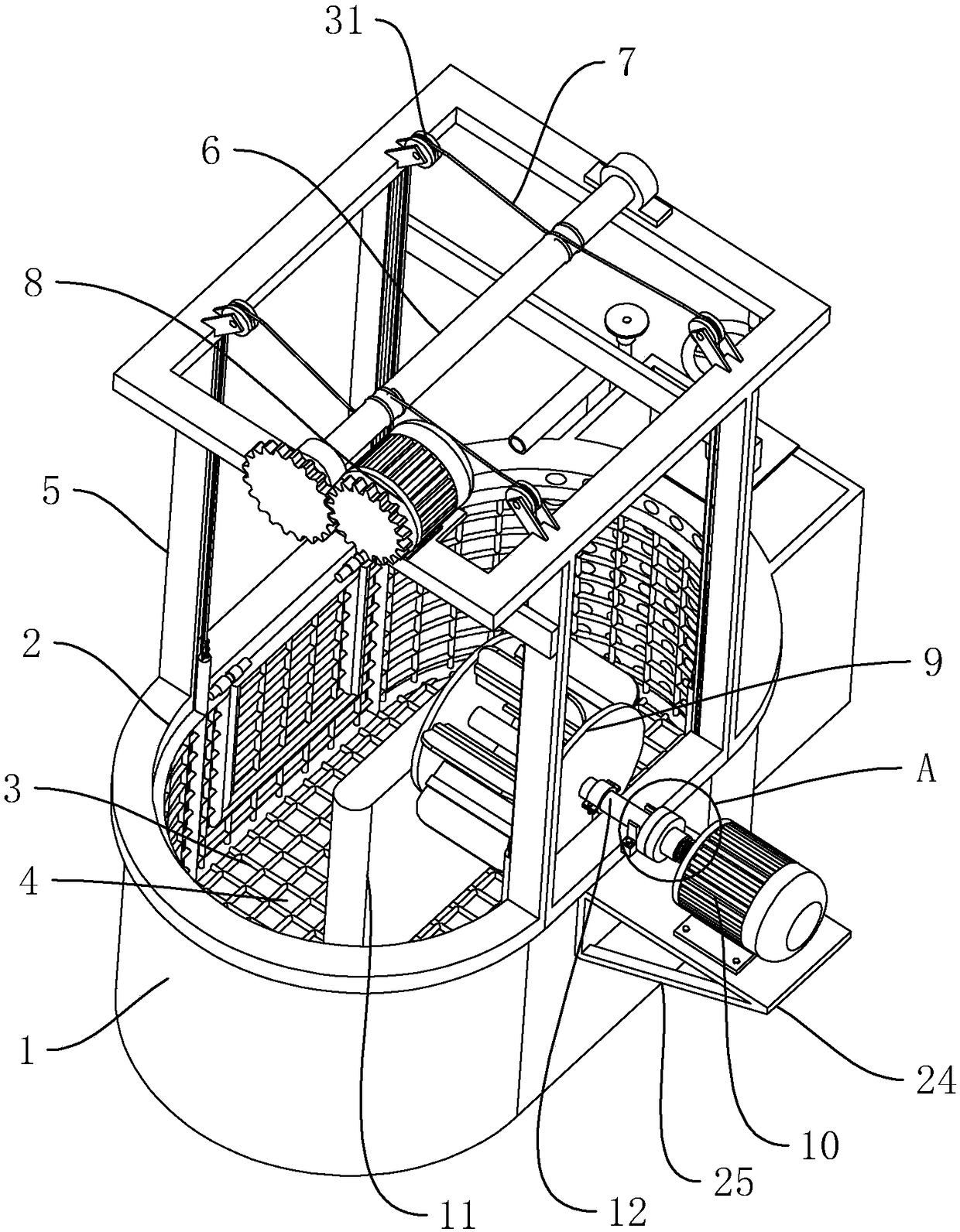

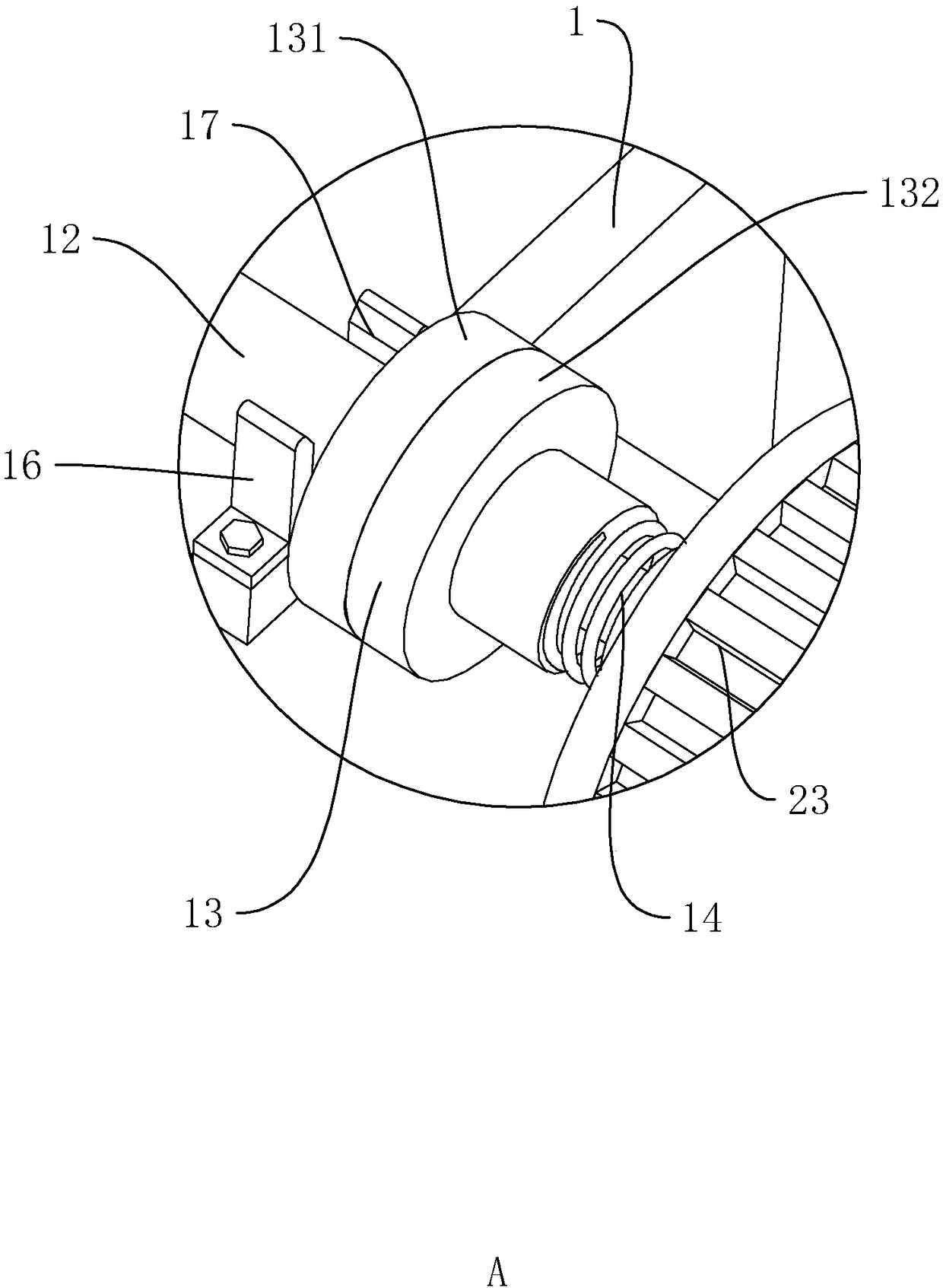

The invention discloses a machining device for ultrasonic grinding of a sapphire lens. The device comprises a support and an ultrasonic vibration loading system; a worktable and a machine tool lathe bed are fixedly arranged on the upper portion of the support, a grinding liquid box is fixedly arranged on the front side of the machine tool lathe bed, the middles of the upper end face and the lowerend face of the grinding liquid box are provided with first through holes, a vertical pipe is arranged in the first through holes through a seal bearing, the upper end and the lower end of the vertical pipe are closed, a driven belt wheel is fixedly arranged on the upper end of the vertical pipe, a vertical motor is fixedly arranged on the front side of the machine tool lathe bed, a driving belt wheel is fixedly arranged on an output shaft of the motor, and the driving belt wheel and the driven belt wheel are connected through a transmission belt. Compared with an existing lens machining device, the structure is simpler, multiple workpieces can be machined at the same time, a grinding liquid supply system is arranged, grinding liquid flowing out operation has the automatic rotating speed adjusting function, a rotating shaft of a grinding head can be automatically and slightly changed along with rotating speed changes of the motor, and the relative position of the grinding head can be changed at any time in the sapphire lens grinding process.

Owner:ZHONGBEI UNIV

Full-automatic mold sleeving machine

The invention discloses a full-automatic mold sleeving machine. The full-automatic mold sleeving machine comprises a mounting frame, a mold platform, an assembling module and a disassembling module, and the mounting of a rubber V belt and a vulcanization mold can be completed in a full-automatic mode through the assembling module, after the vulcanization operation is finished, the vulcanization mold can be detached through the disassembling module, and the rubber V belt is taken down from the vulcanization mold to be conveyed to the mold platform.

Owner:ZHEJIANG SANLISHI INTELLIGENT EQUIP MFG CO LTD

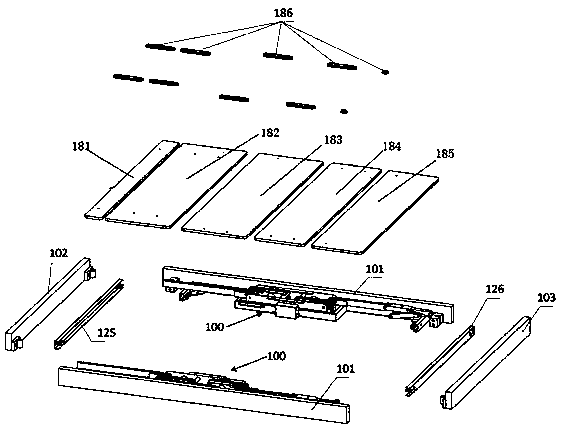

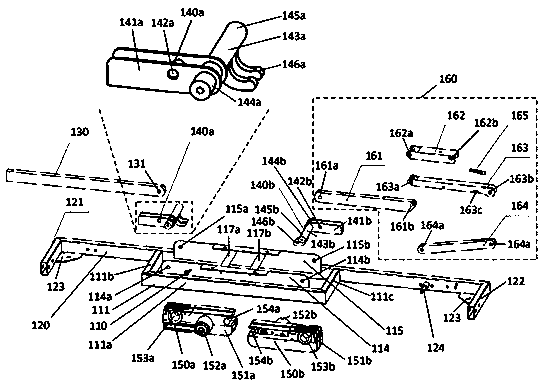

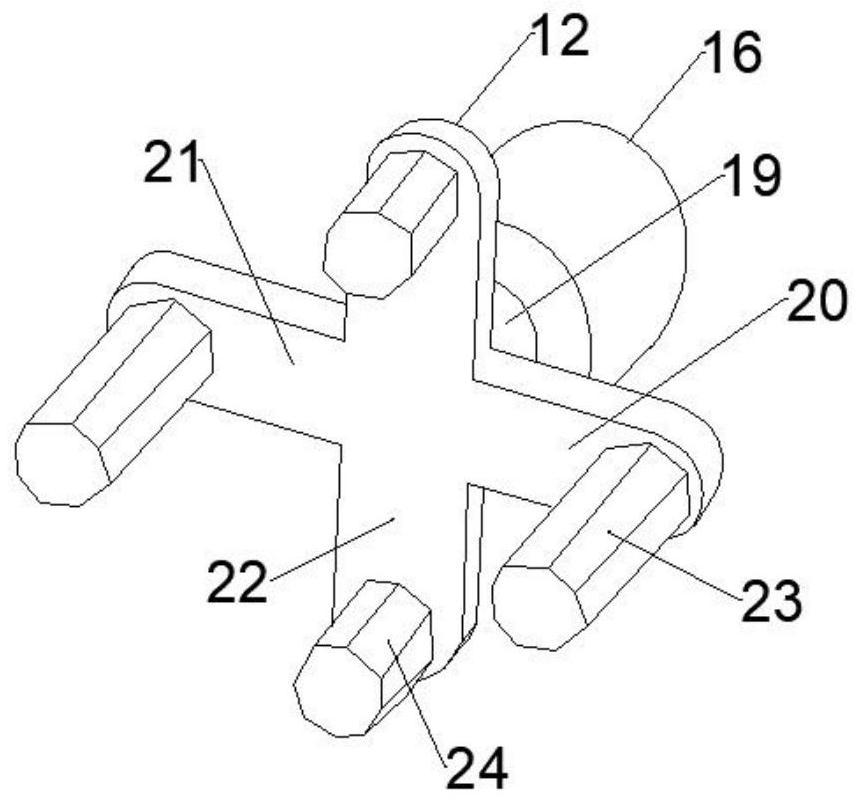

Adjustable electric bed

The invention relates to an adjustable electric bed which comprises a bed plate assembly. The bed plate assembly comprises a head plate, a backboard, a hip plate, a thigh plate and a shank plate whichare distributed in sequence; a bed plate support for the bed plate assembly comprises a pair of transverse rods, longitudinal rods and longitudinal rods, wherein the transverse rods are transverselyspaced, longitudinally aligned and arranged in parallel, and the longitudinal rods are longitudinally spaced, transversely aligned and arranged in parallel. The driving assembly is installed on the bed plate support and comprises driving supports installed on the opposite sides of the two transverse rods respectively, the driving supports are in a U shape, and an installation space is jointly formed between the driving supports and the transverse rods. The present invention is advantageous in that the body position can be adjusted based on the sleep preference of the user, thereby enabling theuser to obtain the maximum comfort during sleep, and can be easily assembled to improve the assembly efficiency and increase the assembly experience of the user.

Owner:江苏里高智能家居有限公司

Clamping device capable of fixing two ends of textile machinery bobbin

The invention discloses a clamping device capable of fixing two ends of a textile machinery bobbin. The clamping device comprises a support frame, wherein the inner sides of the support frame are connected to connecting blocks; shaft rods are connected to the connecting blocks; the upper ends of the shaft rods penetrate the upper surface of the support frame and are in key connection with driven gears; the driven gears are connected to a first driving motor by driving gears; and the first driving motor is arranged on the upper end of the support frame and is connected to the driving gears in akey connection manner. The clamping device capable of fixing the two ends of the textile machinery bobbin can clamp and fix the two ends of the bobbin, and can fix the interior of the bobbin througha supporting ring, thereby enabling the bobbin to be stably clamped and fixed; when a lifting structure of the clamping device, which is formed by the shaft rods, a chuck, a limiting part and a sliding chute, is used, the shaking of the lifting structure is avoided, and thus, when the bobbin is used, the stability of the bobbin can be further ensured.

Owner:浙江万里虹纺织科技股份有限公司

Coal fired chain grate hot-blast stove and application thereof

InactiveCN105423549ASimple structureEasy to operateDrying gas arrangementsAir heatersCombustion chamberCyclonic spray scrubber

The invention provides a coal fired chain grate hot-blast stove. The coal fired chain grate hot-blast stove comprises a combustion chamber, a chain grate and a heat exchanger. The hot-blast stove is a horizontal stove; a combustion fan is arranged below one fuel adding end of the chain grate; a deslagging machine is mounted below the other end of the chain grate; the heat exchanger is a tube type clean air heat exchanger; a tube pass of the heat exchanger is a clean air channel; a smoke outlet and a clean air outlet are formed in the stove wall of the same side of the hot-blast stove; the smoke outlet is sequentially connected with a cyclone dust collector, a water dust scrubber, a smoke guiding fan and a chimney through pipelines. The coal fired chain grate hot-blast stove is simple in structure and convenient to operate by workers, the combustion chamber temperature is easy to control, and temperature fluctuation of hot air generated by the clean air heat exchanger is stable.

Owner:安徽泰格生物技术股份有限公司

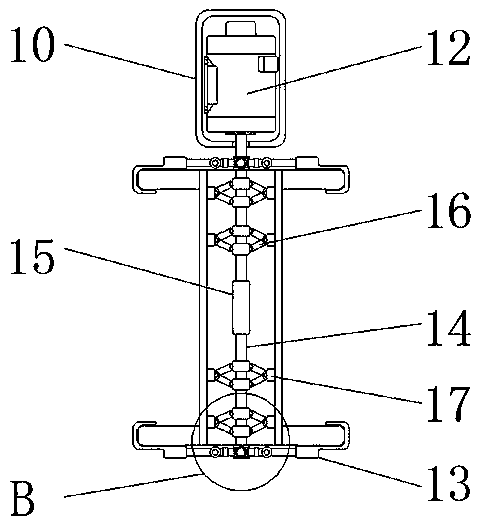

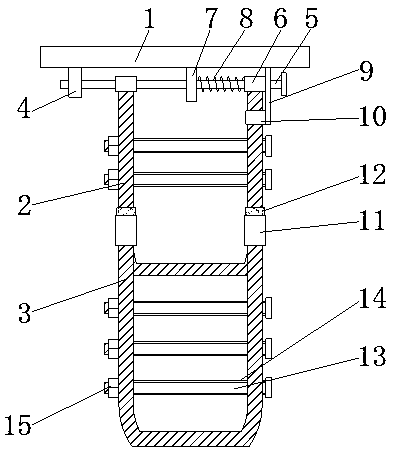

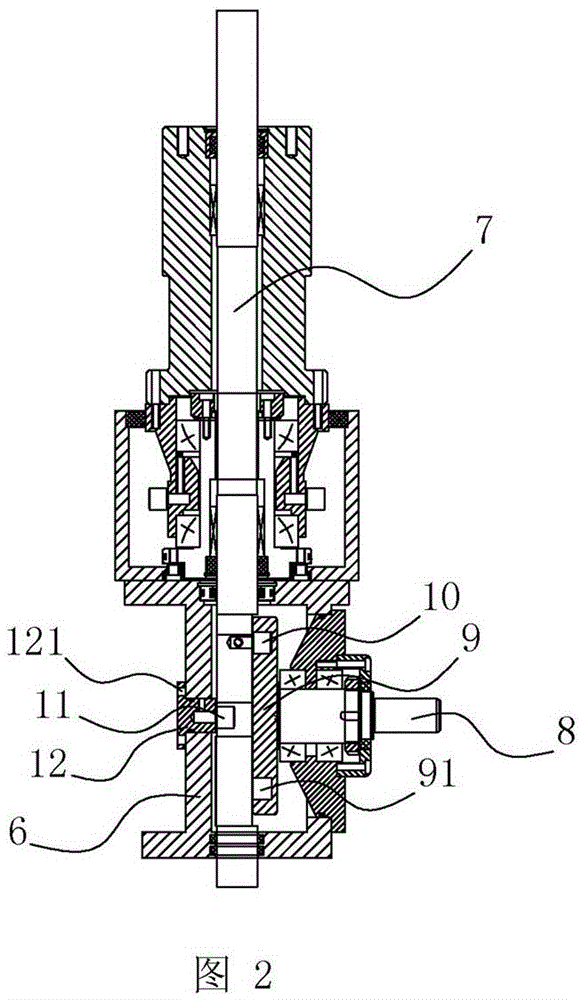

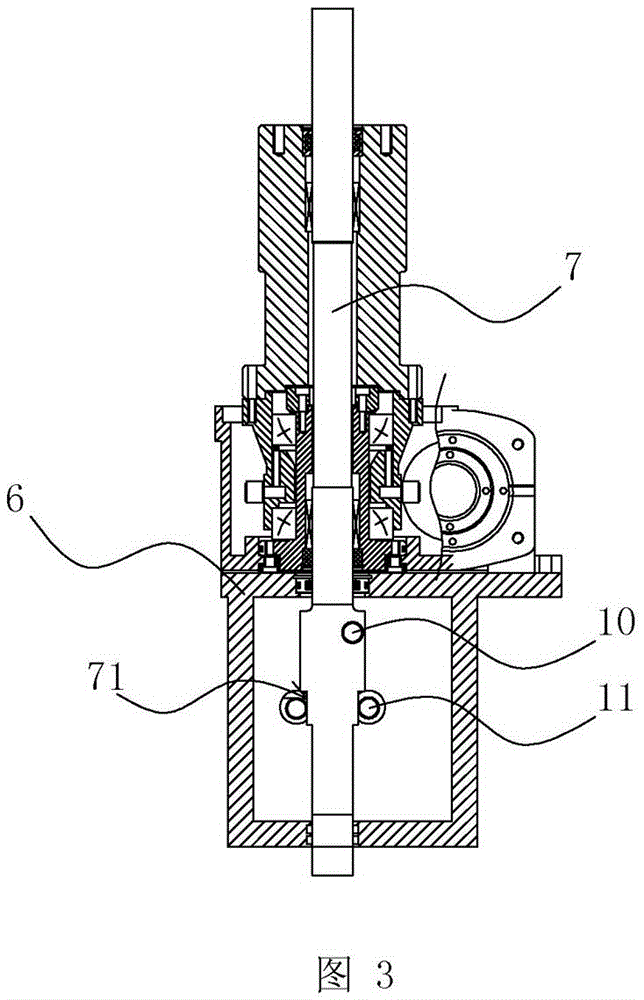

Lifting slicer

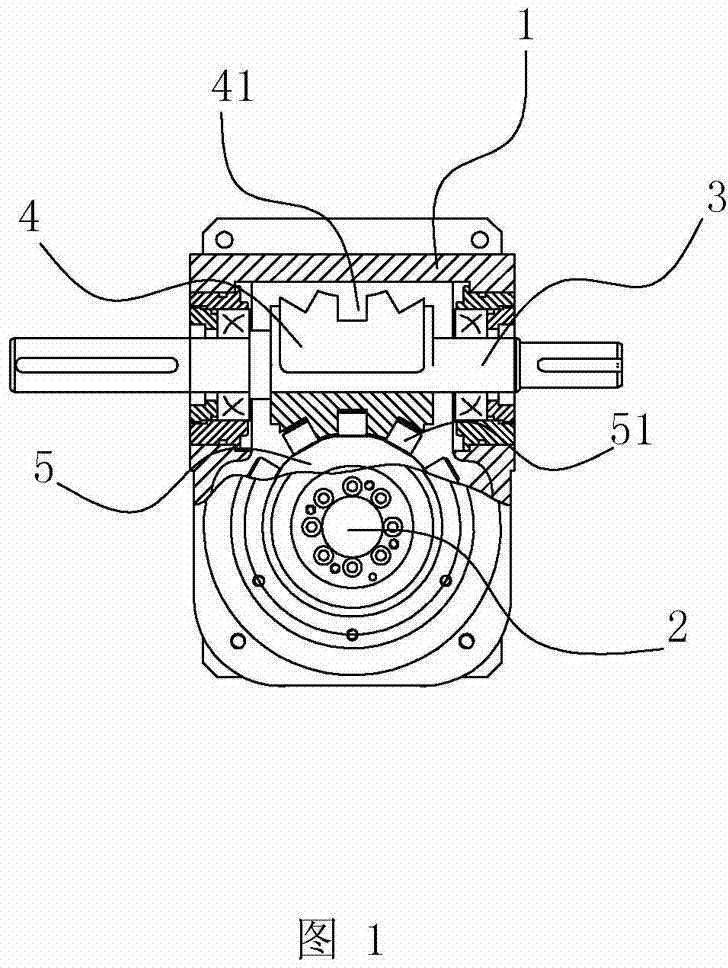

InactiveCN103692231AGuaranteed to work independentlyUp and down stableLarge fixed membersMetal working apparatusMechanical engineeringBearing capacity

The invention provides a lifting slicer, which belongs to the technical field of machinery and is used for solving the problem of poor bearing capacity of the conventional lifting slicer. The lifting slicer comprises a lifter and a slicer, wherein the slicer comprises a slicer box body, a rotating shaft and an input shaft which is inserted into the slicer box body and is connected with an external driving mechanism; an indexing mechanism is arranged in the slicer box body; the lifter comprises a lifter box body and an output shaft connected with the lifter box body in a sliding way; one end of the output shaft extends out of the lifter box body; the lifter box body is provided with a force input shaft; one end of the force input shaft extends out of the slicer box body and is connected with an input shaft through a transmission mechanism, and the other end of the force input shaft is connected with the output shaft through a lifting driving structure. The lifter slicer has the advantage of high bearing capacity.

Owner:TAIZHOU YONGFA MACHINE MFG

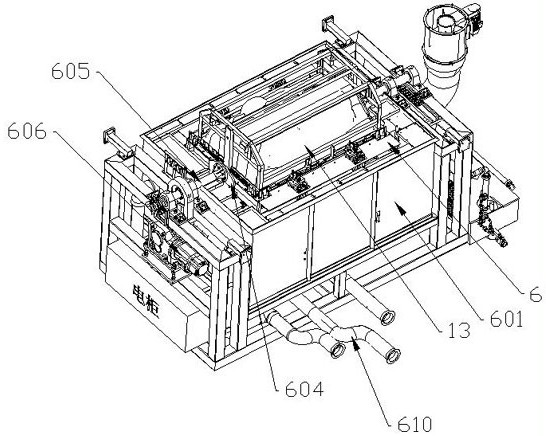

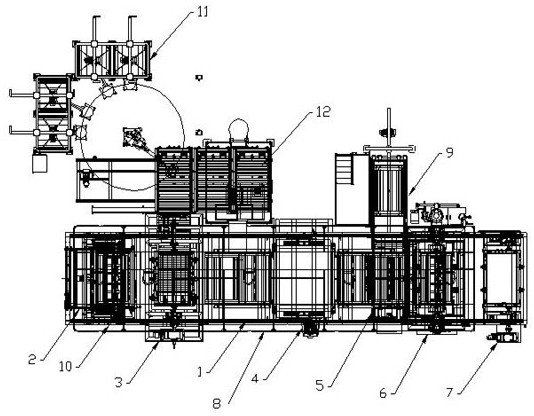

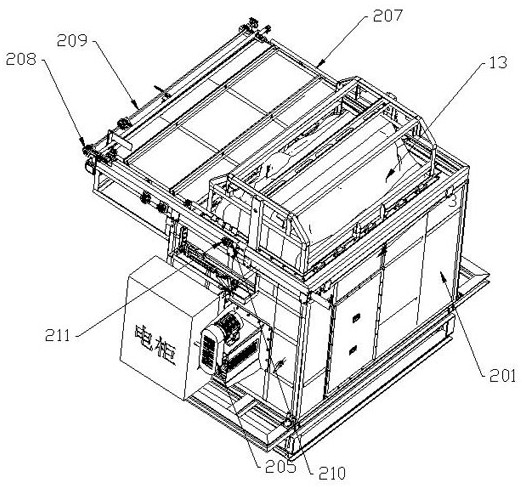

A slush molding production line for automotive interior parts

ActiveCN108858934BReasonable distributionShorten the path of travelCoatingsProduction lineHeating furnace

Owner:NANTONG CHAODA EQUIP CO LTD +1

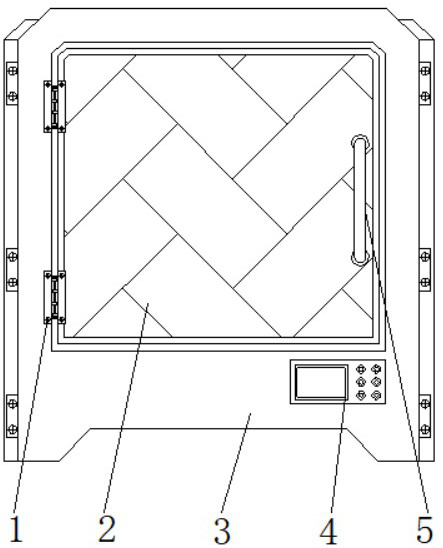

Angle-adjustable 3D printing device

PendingCN112497742AEasy to replaceSmooth rotationManufacturing driving meansManufacturing auxillary operationsComputer printingEngineering

The invention discloses an angle-adjustable 3D printing device which comprises a printer body, a door body is arranged at one end of the outer wall of the printer body, hinges are installed at the twoends of one side of the door body, a handle is installed on one side of the outer wall of the door body, and a feeding roller is installed at the top end of a raw material body. By arranging a rotating structure, when the device needs 3D printing, the raw material body needs to be placed behind the printer body, then the raw material body enters a second driving block from the feeding roller to be heated, and after heating of the raw material body is finished, an external power source of a second servo motor is switched on, and the second servo motor drives a first belt on the surface to rotate and is matched with a rotating second belt, so that a printing head on the second driving block can move forwards, backwards, leftwards and rightwards for printing.

Owner:常州江苏大学工程技术研究院

Fur bleaching pool

ActiveCN108624728AReduce weightEasy accessLeather/skins/hides/pelt chemical treatment apparatusIndustrial engineeringDewatering

The invention discloses a fur bleaching pool. The fur bleaching pool comprises a pool body which is provided with a bleaching tank, wherein a lifting basket used for holding fur is arranged in the bleaching tank; the lifting basket is provided with a plurality of filtering holes; the part, located above the lifting basket, of the pool body is provided with a frame; the frame is rotatably providedwith a rotating roller; a lifting rope is arranged between the rotating roller and the lifting basket; and the frame is provided with a first driving mechanism which drives the rotating roller to rotate so as to control the lifting basket to move up and down. The fur bleaching pool provided by the invention has the following advantages: through arrangement of the lifting basket on the pool body, bleached fur can be lifted for natural dewatering, so the weight of the fur is reduced, and a bleaching solution is not needed to be discharged; the cost of processing is reduced; and the fur is convenient to take by an operator.

Owner:桐乡市志强皮毛染色厂

Hydraulic lifting platform

InactiveCN108439283AUp and down stableAvoid safety accidentsSafety devices for lifting equipmentsHydraulic cylinderArchitectural engineering

The invention discloses a hydraulic lifting platform, which comprises a top plate and a bottom plate. The bottom of the top plate is fixedly connected with a hinge seat; the top plate is connected with a pin shaft through the hinge seat in a rotatable manner; the outer surface of the pin shaft is connected with a sleeve and a baffle plate in a sleeving manner; the bottom of the sleeve is fixedly connected with an upper ladder; one side of the sleeve is fixedly connected with a clamping seat; the bottom of one side of the clamping seat is fixedly connected with a limiting block; the outer surface of the upper ladder is welded with a fixed sleeve; the inner wall of the fixed sleeve is connected with a lower ladder in a sliding manner; one side of the lower ladder is provided with a cross rod; one end of the cross rod penetrates through and extends to the other side of the lower ladder; one end of the cross rod is in threaded connection with a nut; and the outer surface of the cross rod is fixedly connected with an antiskid layer. By the arrangement of the upper ladder, the lower ladder, the hinge seat, the pin shaft, the sleeve, the baffle plate, a torsion spring, the bottom plate, ashear bracket, a hydraulic cylinder and springs, the hydraulic lifting platform solves the problem that a worker gets onto and gets off the lifting platform inconveniently when the lifting platform drops down.

Owner:河南省通用矿山起重机械有限公司

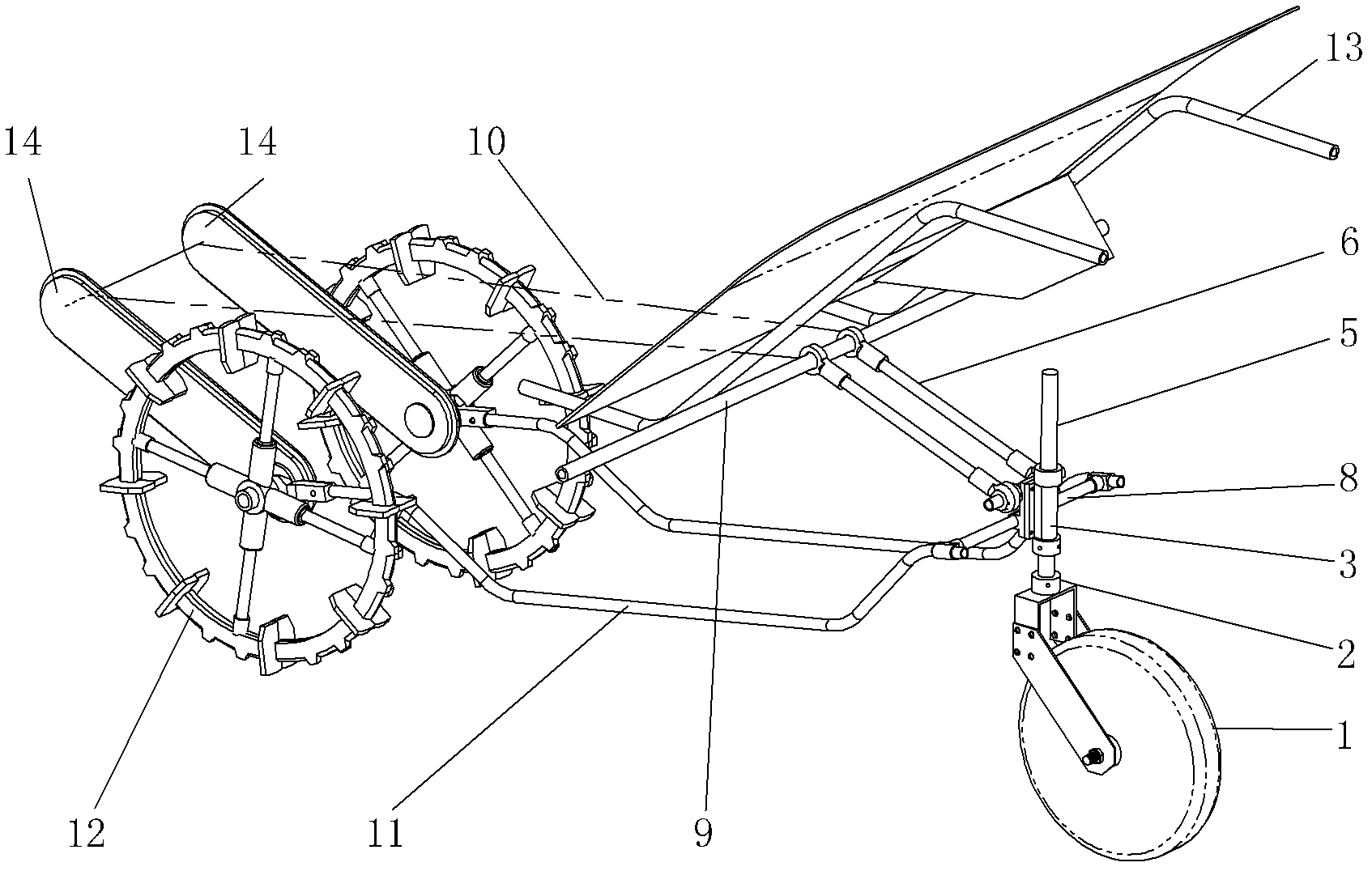

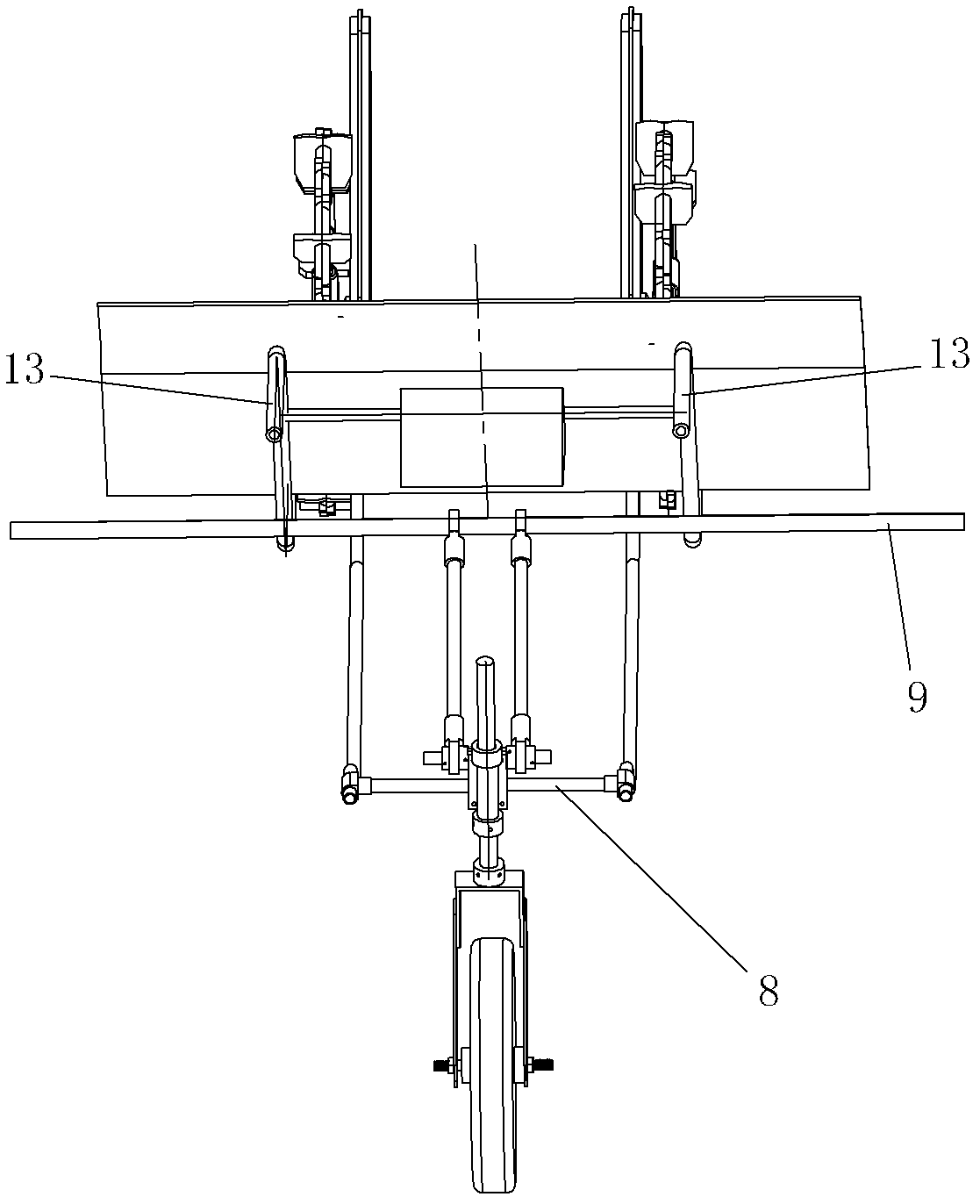

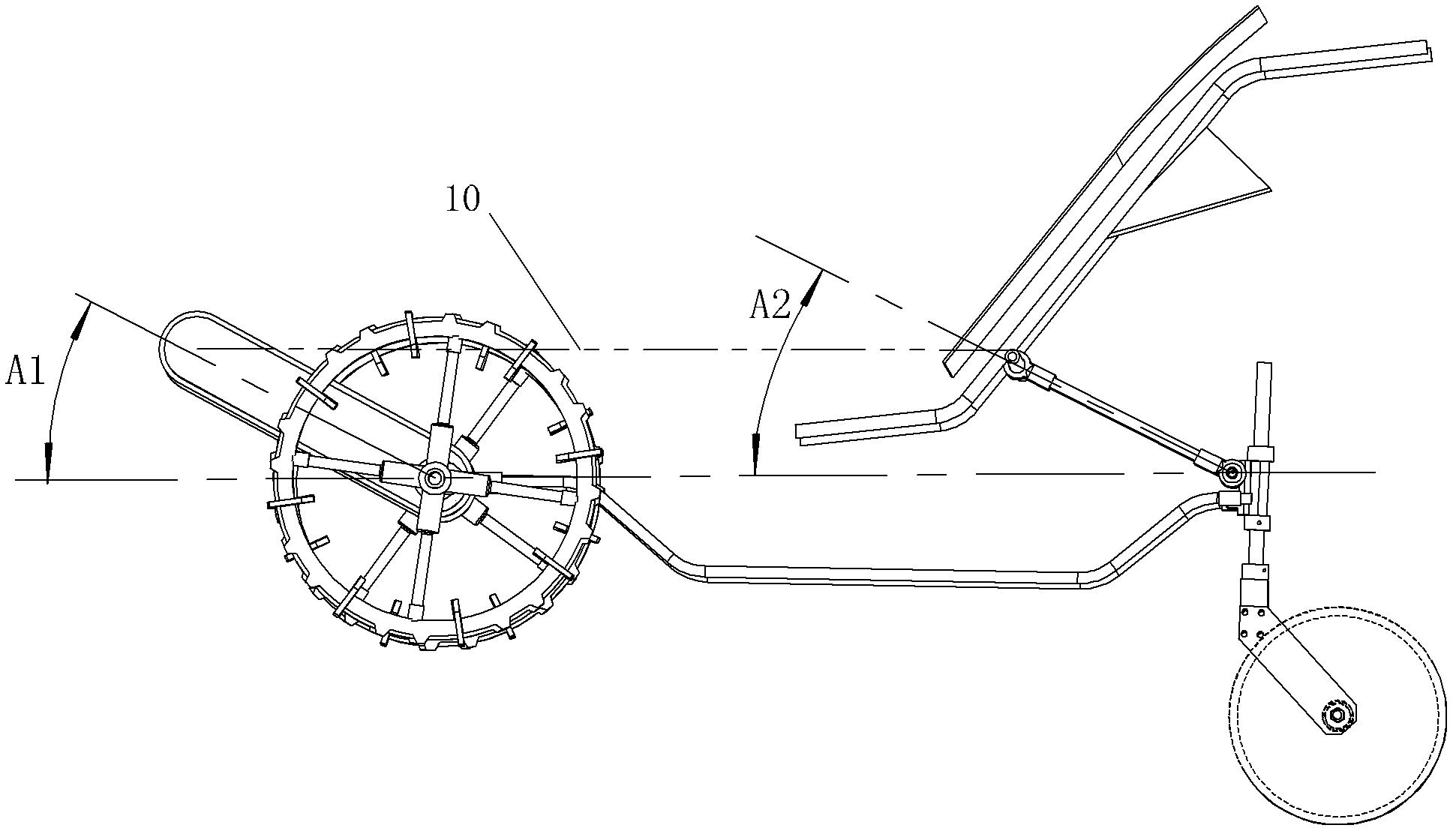

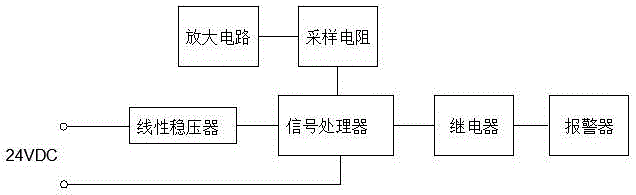

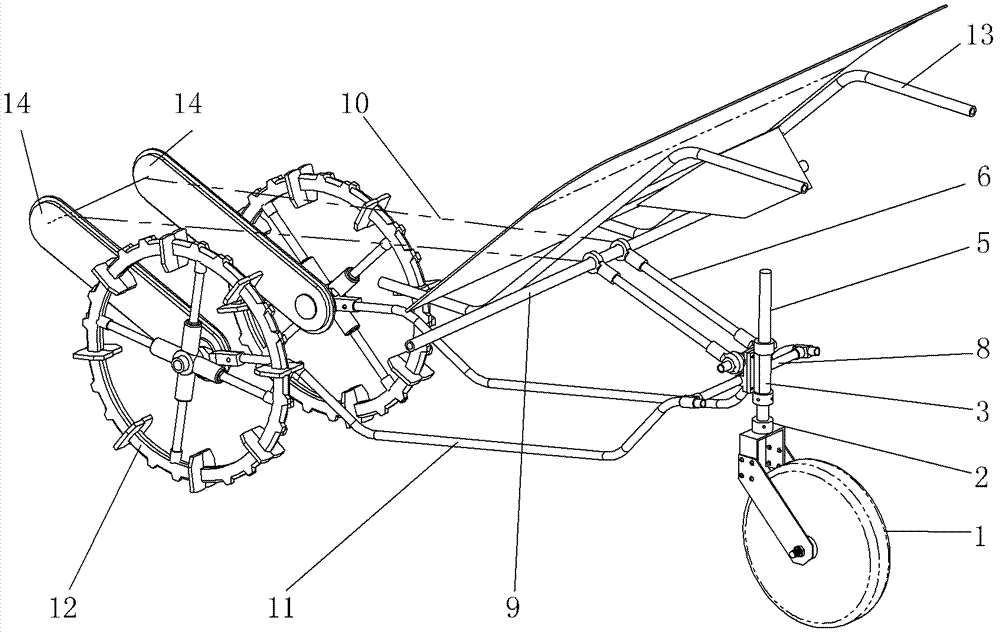

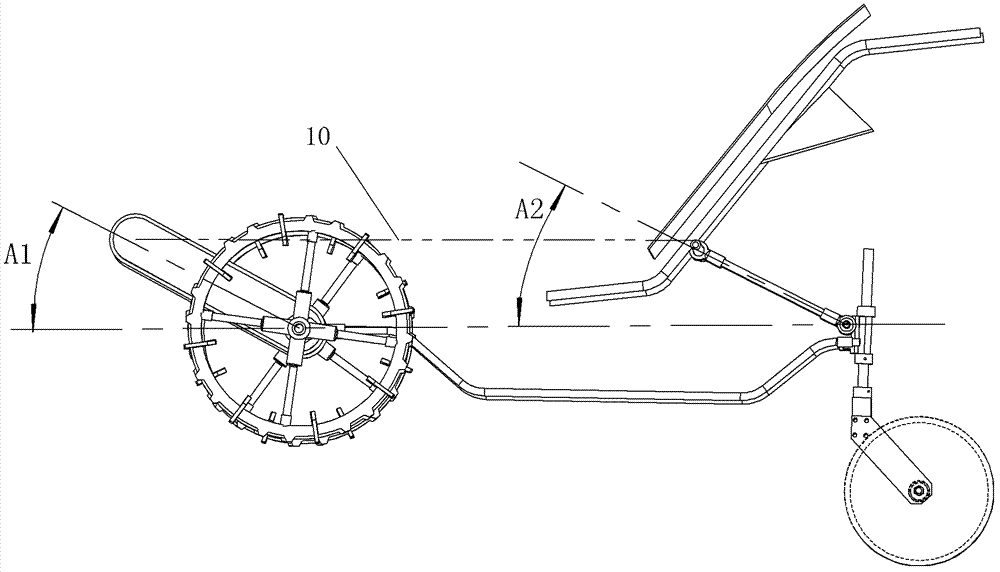

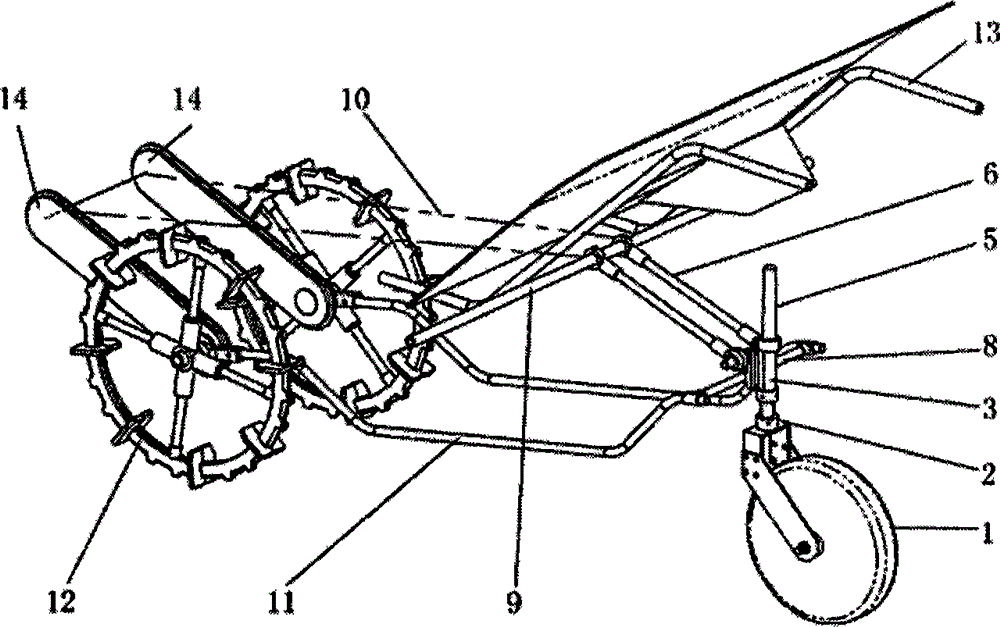

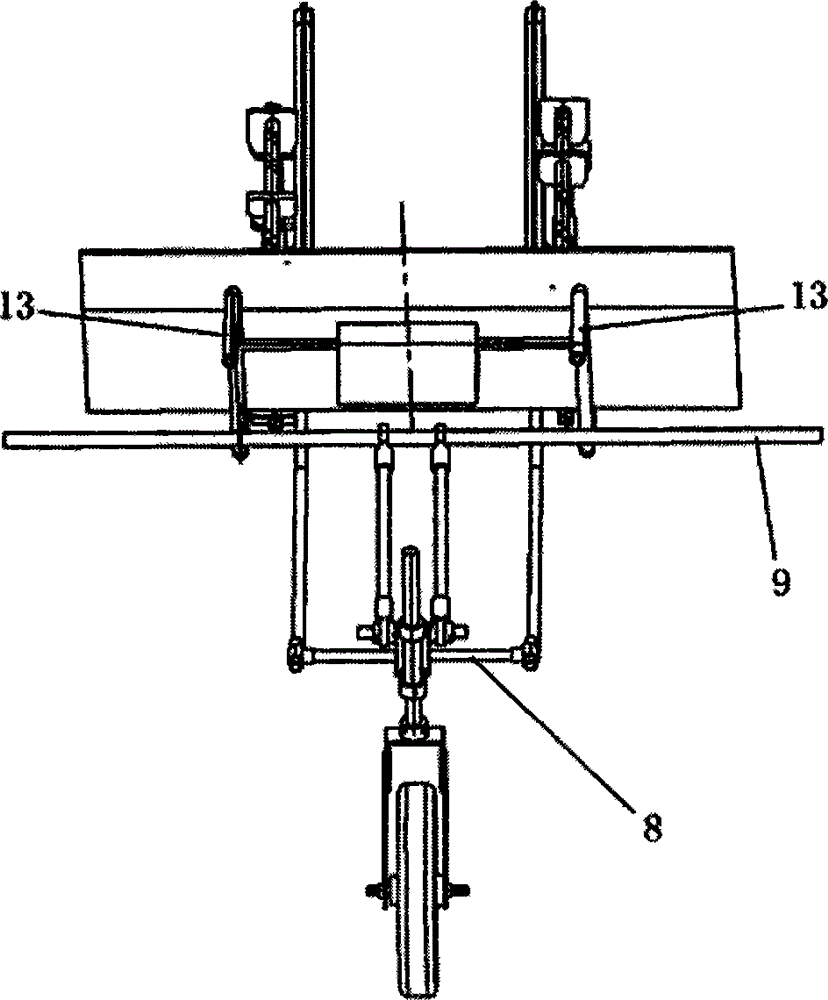

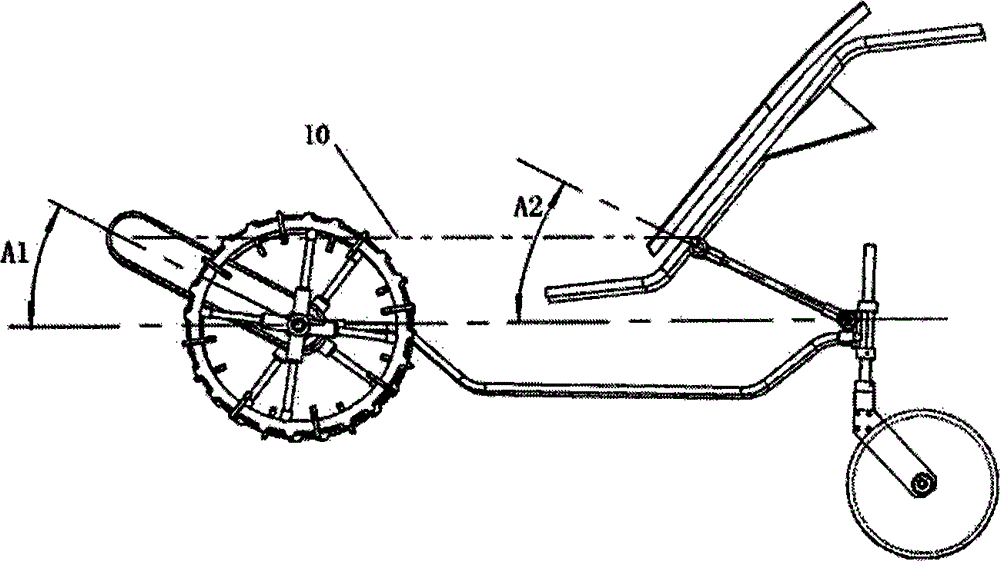

Walking type rice seedling planter traveling mechanism with machine frame capable of doing up-and-down movement

InactiveCN102379182ARealize continuous monitoringEfficient captureTransplantingEngineeringWheel and axle

The invention relates to a traveling mechanism of agricultural machinery and aims to solve the technical problem that the provided traveling mechanism can walk stably in an unmanned state, and the machine frame can do an up-and-down movement, so that the unmanned requirements can be met. The invention adopts the technical scheme that the walking type rice seedling planter traveling mechanism comprises traveling wheels respectively mounted on the left side and the right side of a rice seedling planter and is characterized in that a tail wheel for adjusting the direction is provided; the traveling wheels and the tail wheel are respectively hinged onto a curved bar in a four-bar mechanism, the curved bar is U-shaped, and the left side end parts of the two bar walls of the curved bar are fixed with the wheel shafts of the two traveling wheels respectively; a wheel stand shaft sleeve is fixed at the connecting end of the right sides of the two bar walls of the curved bar; and the wheel stand equipped with the tail wheel can be rotationally inserted in the wheel stand shaft sleeve.

Owner:ZHEJIANG SCI-TECH UNIV

Horizontal ring cutter numerical control cutting device

PendingCN110370362AAchieve individual rotationRotation effectMetal working apparatusNumerical controlEngineering

The invention relates to a horizontal ring cutter numerical control cutting device. The numerical control cutting device comprises a conveying mechanism, a gantry and a pressing support, wherein the conveying mechanism comprises a conveying support, and a working platform is arranged on the conveying support; the working platform is jointly composed of a rotating platform and a fixed platform which are distributed up and down, the rotating platform is driven by a rotating mechanism to rotate, and the fixed platform is driven by a horizontal moving mechanism to move; the gantry crosses the twosides in the width direction of the conveying support; and the pressing support comprises an upper pressing support, the upper pressing support is driven by a lifting mechanism to vertically ascend and descend, a plurality of pressing plates are arranged on the upper pressing support, and each pressing plate is driven by a following mechanism to move. The horizontal ring cutter numerical control cutting device has the advantages that due to the cooperation among the conveying mechanism, the gantry and the pressing support, not only can the deviation of sponge be avoided, but also the smooth rotation of the sponge can be ensured.

Owner:南通宏昇机械配件有限公司

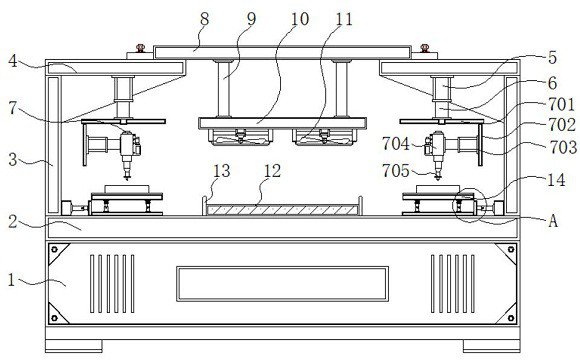

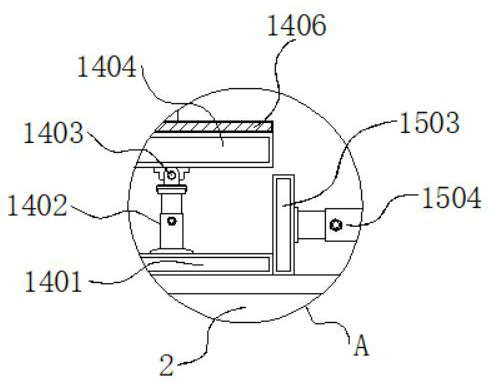

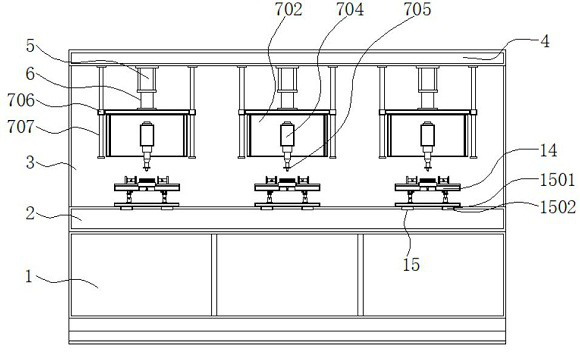

Positionable automatic welding device for machining cooling fin of computer CPU

InactiveCN112139716AAvoid offsetImprove cooling efficiencyWelding/cutting auxillary devicesAuxillary welding devicesPhysicsHeat sink

The invention discloses a positionable automatic welding device for machining a cooling fin of a computer CPU and relates to the technical field of cooling fin welding, the positionable automatic welding device comprises a machine body, a welding structure, a conveying belt and a positioning mechanism, a workbench is fixed above the machine body, back plates are installed on the two sides of the outer portion of the upper portion of the workbench, and a top plate is fixed to the upper sides of the back plates. An air cylinder is mounted below the middle of the top plate, a piston rod is arranged on the lower side of the air cylinder, the welding structure is mounted below the piston rod, an upper plate is mounted above the top plate, connecting rods are fixed to the two sides of the lowerportion of the upper plate, a mounting plate is fixed to the lower portions of the connecting rods, and cooling fans are mounted on the two sides of the lower portion of the mounting plate. The positionable automatic welding device has the beneficial effects that the height of a lifting plate can be conveniently adjusted in a rising and falling mode through the air cylinder and the piston rod so as to drive a welding gun and a welding head to descend, the position of the welding gun can be conveniently adjusted through an electric push rod, and a cooling fin main body can be conveniently welded through the welding gun and the welding head.

Owner:东莞市夯牛机电科技有限公司

Compression packaging machine for sofa accessories

Owner:HAINING GELIN FURNITURE +1

fur bleaching pool

ActiveCN108624728BReduce weightEasy accessLeather/skins/hides/pelt chemical treatment apparatusStructural engineeringMechanical engineering

The invention discloses a fur bleaching pool. The fur bleaching pool comprises a pool body which is provided with a bleaching tank, wherein a lifting basket used for holding fur is arranged in the bleaching tank; the lifting basket is provided with a plurality of filtering holes; the part, located above the lifting basket, of the pool body is provided with a frame; the frame is rotatably providedwith a rotating roller; a lifting rope is arranged between the rotating roller and the lifting basket; and the frame is provided with a first driving mechanism which drives the rotating roller to rotate so as to control the lifting basket to move up and down. The fur bleaching pool provided by the invention has the following advantages: through arrangement of the lifting basket on the pool body, bleached fur can be lifted for natural dewatering, so the weight of the fur is reduced, and a bleaching solution is not needed to be discharged; the cost of processing is reduced; and the fur is convenient to take by an operator.

Owner:桐乡市志强皮毛染色厂

A lifting divider

InactiveCN103692231BGuaranteed to work independentlyAdjust the range of up and downLarge fixed membersMetal working apparatusMechanical engineeringBearing capacity

The invention provides a lifting slicer, which belongs to the technical field of machinery and is used for solving the problem of poor bearing capacity of the conventional lifting slicer. The lifting slicer comprises a lifter and a slicer, wherein the slicer comprises a slicer box body, a rotating shaft and an input shaft which is inserted into the slicer box body and is connected with an external driving mechanism; an indexing mechanism is arranged in the slicer box body; the lifter comprises a lifter box body and an output shaft connected with the lifter box body in a sliding way; one end of the output shaft extends out of the lifter box body; the lifter box body is provided with a force input shaft; one end of the force input shaft extends out of the slicer box body and is connected with an input shaft through a transmission mechanism, and the other end of the force input shaft is connected with the output shaft through a lifting driving structure. The lifter slicer has the advantage of high bearing capacity.

Owner:TAIZHOU YONGFA MACHINE MFG

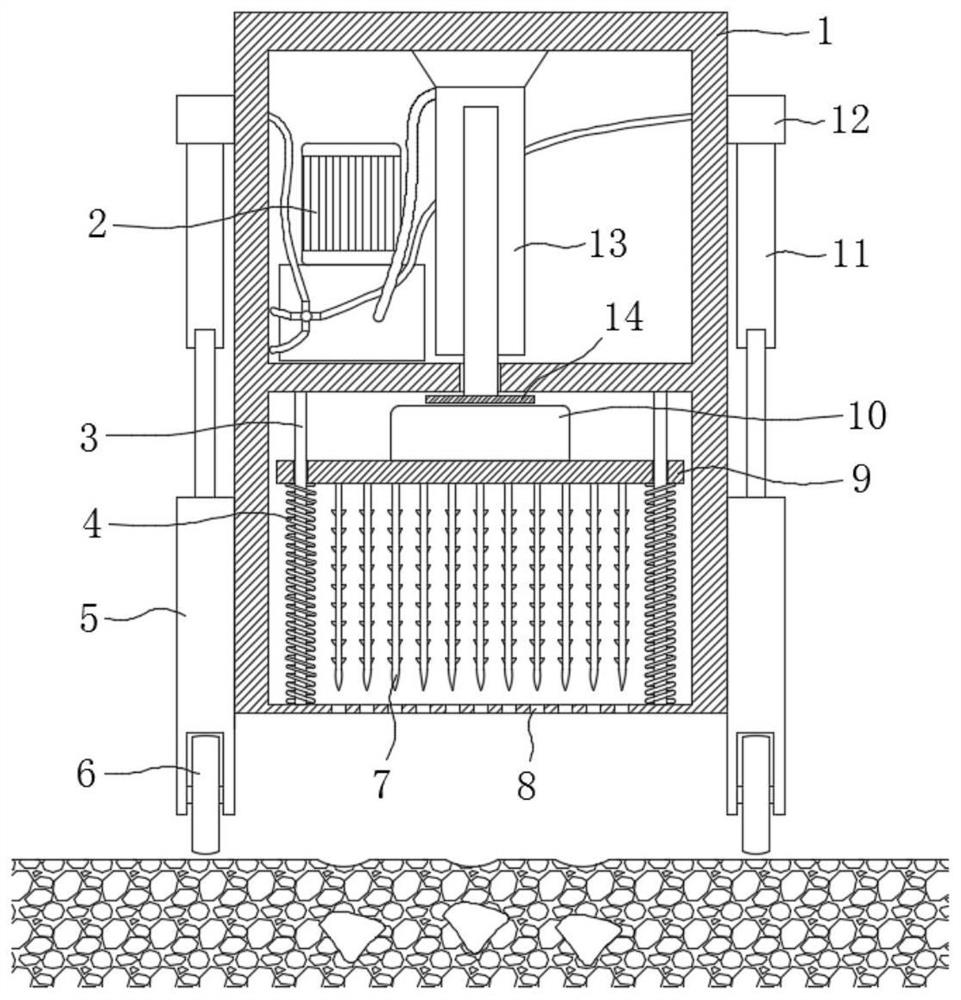

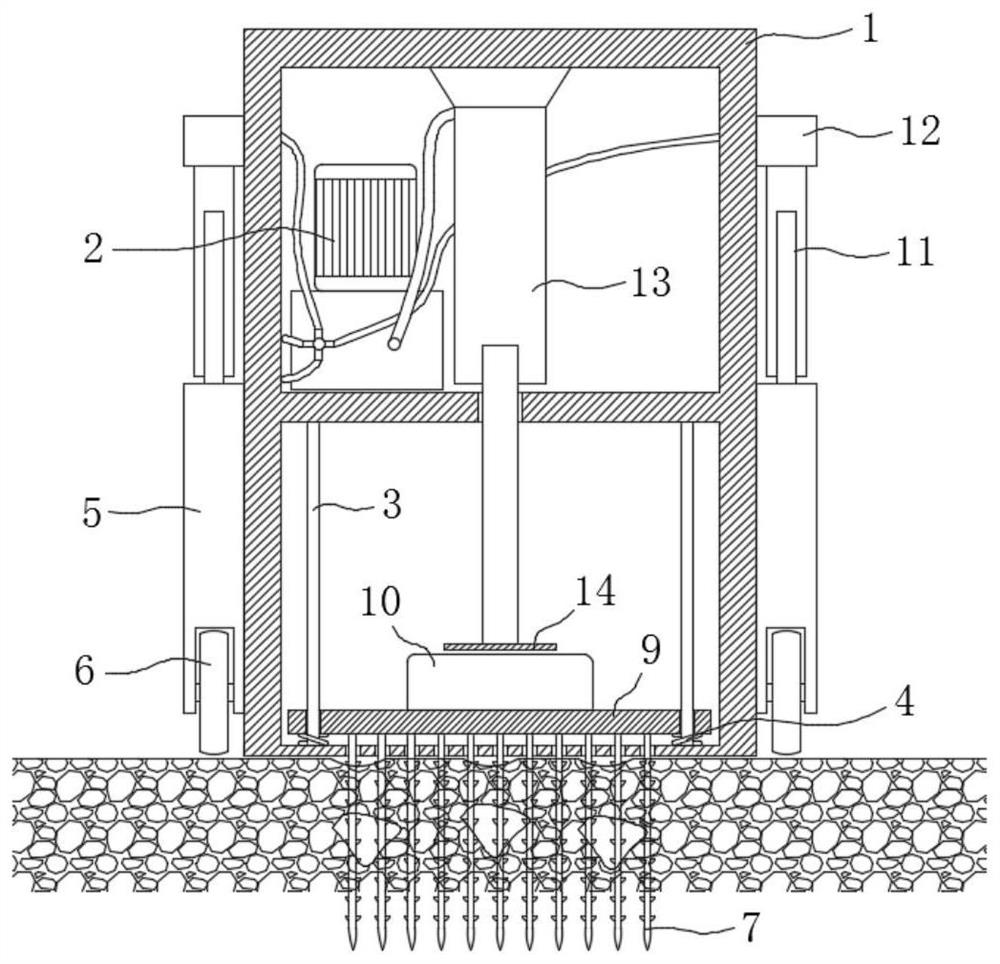

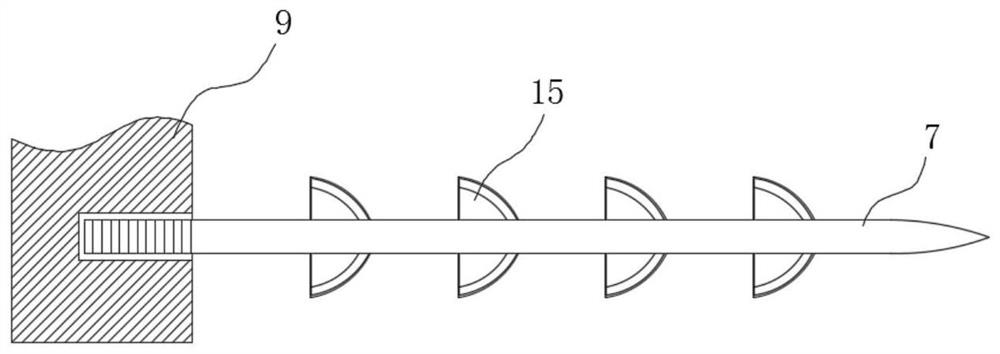

Road surface maintenance device for road and bridge construction

ActiveCN110331712BUp and down stableEasy to work on siteSoil preservationPavement maintenanceArchitectural engineering

The invention discloses a road surface maintenance device for road and bridge construction, which comprises a machine body, which is divided into a hydraulic chamber and a tamping chamber from top to bottom, and four hydraulic moving mechanisms are symmetrically installed on the side wall of the body. The inner bottom wall and the inner top wall of the tamping chamber are symmetrically and fixedly installed with a plurality of positioning columns, and a tamping plate is slidably installed on the plurality of positioning columns, and a return spring is installed on each of the positioning columns, and the return spring The upper end and the lower end are respectively fixed on the lower bottom surface of the tamping plate and the lower bottom wall of the tamping chamber. The invention uses a hydraulic moving mechanism to make the machine body more convenient to move and work at the construction site, and can easily move to any construction area, reducing labor force. The conical thorns and arc-shaped deflectors penetrate into the foundation to vibrate, so that the gaps in the foundation and The hollow layer is filled tightly by the surrounding vibrating and soft soil layer, which increases the firmness of the foundation, and there is no need to re-excavate the foundation for filling, reducing the labor and workload of the construction team.

Owner:中铁城乡环保工程有限公司 +1

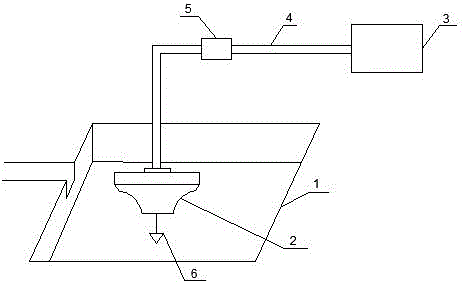

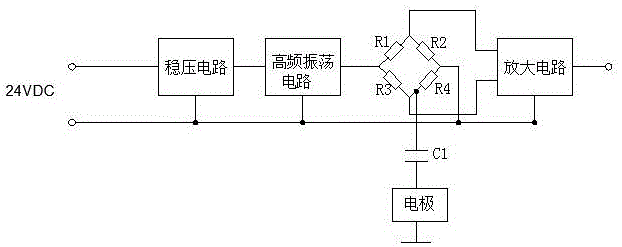

High-frequency oscillating wave capacitance method oil leakage detection and alarm device

PendingCN106802217AThe test results are safe and reliableImprove stabilityDetection of fluid at leakage pointCapacitanceAlarm device

The invention discloses a high-frequency oscillating wave capacitance method oil leakage detection and alarm device comprising a water tank, a detector and a converter. The water tank is arranged at the low position of the tank field of an oil storage tank. The detector is arranged on the water surface. The signal output end of the detector is connected with the signal input end of the converter through a cable. The power supply end of the detector is connected with a power supply through the converter. The detector comprises a shell and a detection circuit arranged in the shell. An electrode is arranged on the detection circuit. The upper end of the electrode is connected in series with the detection circuit, and the lower end is arranged under the water surface. The converter comprises a shell and a conversion circuit arranged in the shell. The input end of the conversion circuit is connected with the output end of the detection circuit. The output end of the conversion circuit is connected with an alerter. The phenomenon of oil leakage can be accurately detected in real time and alarming can be performed so as to be safe and reliable.

Owner:PINGDINGSHAN SHENMA WANLI CHEM

Walking type rice seedling planter traveling mechanism with machine frame capable of doing up-and-down movement

InactiveCN102379182BRealize continuous monitoringEfficient captureTransplantingEngineeringMechanical engineering

The invention relates to a traveling mechanism of agricultural machinery and aims to solve the technical problem that the provided traveling mechanism can walk stably in an unmanned state, and the machine frame can do an up-and-down movement, so that the unmanned requirements can be met. The invention adopts the technical scheme that the walking type rice seedling planter traveling mechanism comprises traveling wheels respectively mounted on the left side and the right side of a rice seedling planter and is characterized in that a tail wheel for adjusting the direction is provided; the traveling wheels and the tail wheel are respectively hinged onto a curved bar in a four-bar mechanism, the curved bar is U-shaped, and the left side end parts of the two bar walls of the curved bar are fixed with the wheel shafts of the two traveling wheels respectively; a wheel stand shaft sleeve is fixed at the connecting end of the right sides of the two bar walls of the curved bar; and the wheel stand equipped with the tail wheel can be rotationally inserted in the wheel stand shaft sleeve.

Owner:ZHEJIANG SCI-TECH UNIV

A processing device for ultrasonic grinding sapphire lens

InactiveCN108381376BHigh precisionImprove grinding efficiencyOptical surface grinding machinesGrinding drivesRotational axisTransmission belt

The invention discloses a machining device for ultrasonic grinding of a sapphire lens. The device comprises a support and an ultrasonic vibration loading system; a worktable and a machine tool lathe bed are fixedly arranged on the upper portion of the support, a grinding liquid box is fixedly arranged on the front side of the machine tool lathe bed, the middles of the upper end face and the lowerend face of the grinding liquid box are provided with first through holes, a vertical pipe is arranged in the first through holes through a seal bearing, the upper end and the lower end of the vertical pipe are closed, a driven belt wheel is fixedly arranged on the upper end of the vertical pipe, a vertical motor is fixedly arranged on the front side of the machine tool lathe bed, a driving belt wheel is fixedly arranged on an output shaft of the motor, and the driving belt wheel and the driven belt wheel are connected through a transmission belt. Compared with an existing lens machining device, the structure is simpler, multiple workpieces can be machined at the same time, a grinding liquid supply system is arranged, grinding liquid flowing out operation has the automatic rotating speed adjusting function, a rotating shaft of a grinding head can be automatically and slightly changed along with rotating speed changes of the motor, and the relative position of the grinding head can be changed at any time in the sapphire lens grinding process.

Owner:ZHONGBEI UNIV

A paper core lifting mechanism

Owner:湖南恒安生活用纸有限公司 +1

Large-scale lifting screen performance machine with long-span synchronous lifting arm

ActiveCN102168787BSmooth liftUp and down stableStands/trestlesIdentification meansFar distanceMechanical engineering

The invention relates to a large-scale lifting screen performance machine with a long-span synchronous lifting arm, which is mainly formed by a lifting screen, fixed arms, telescopic arms, a driving mechanism, transmission mechanisms and a balance weight mechanism, wherein the tops of both sides of the lifting screen are fixed to the top ends of the two telescopic arms respectively; the two telescopic arms are arranged in the two fixed arms longitudinally in a lifting way; a middle driving mechanism which corresponds to the top ends of the fixed arms is fixedly arranged on a fixture in the rear of the lifting screen; the synchronous transmission mechanisms are arranged on both sides in the lateral direction of the driving mechanism; the driving mechanism drives the telescopic arms to drive the lifting screen to lift by the transmission mechanisms; and the balance weight mechanism are connected to the bottom ends of the two telescopic arms and the lifting screen commonly. The large-scale lifting screen performance machine has scientific and reasonable structural design, runs stably and is safe and reliable and the design desire of the extra large-scale outdoor lifting screen is realized, so that audiences can enjoy the spectacular scene of lifting large-scale light-emitting diode (LED) display frames slowly at a far distance.

Owner:马超

A multi-terrain pump

ActiveCN107165851BStable jobExtended service lifePump componentsPump installationsTerrainEngineering

The invention relates to the technical field of mechanical electricity, and discloses a pump suitable for multiple terrains. The pump comprises a pump base, two position fixing grooves are formed in the pump base, sliding buckles are arranged on the inner sides of the position fixing grooves, a traction wire is welded to the bottoms of the sliding buckles, two clamping blocks are welded to one end of the traction wire, a gear is clamped to the bottom ends of the two clamping blocks, supporting columns are rotatably connected to the outer sides of the gears, racks are welded to the outer portions of the two sides of the supporting columns, a belt is rotatably connected to the outer sides of the gears, one end of the belt is in transmission connection with a rotating disc, and the front face of the rotating disc is rotatably connected with a rotating handle. In the running process of the pump suitable for the multiple terrains, the rotating handle is swung to drive the rotating disc to rotate, the rotating disc drives the gears to rotate through the belt, through cooperation of the gears and the racks, the supporting columns are adjusted to stretch out and draw back, the angle of a the pump base is adjusted, the pump and a motor can be kept horizontal at any place, and the pump can be suitable for the different terrains to telescopically work.

Owner:湖南天一奥星泵业有限公司

Paper core lifting mechanism

Owner:湖南恒安生活用纸有限公司 +1

Traveling device of rice transplanter

InactiveCN104782288AEfficient captureSmooth goingTransplantingAgricultural engineeringWheel and axle

The invention relates to a traveling device of a rice transplanter. The traveling device comprises traveling wheels mounted on the left and right sides of the rice transplanter; the traveling device is characterized by being further configured with a tail wheel used for direction adjustment; the two traveling wheels and the tail wheel are hinged to a cranked lever in a four-lever mechanism respectively; the cranked lever is U-shaped, the end parts of the left sides of two lever walls of the cranked lever are fixed with a wheel shaft of the two traveling wheels respectively, and a connecting end of the right sides of the two lever walls is fixed with a wheel frame shaft sleeve; a wheel frame configured with the tail wheel is rotatably inserted and mounted in the wheel frame shaft sleeve.

Owner:于维嘉

Overturning, adjusting and airing device for raisin airing

InactiveCN112984986APrevent hangingAvoid damageDrying chambers/containersDrying solid materialsBrakeChain link

The invention discloses an overturning, adjusting and airing device for raisin airing. The overturning, adjusting and airing device comprises a plurality of airing racks and an overturning main body, the overturning main body is erected between the airing racks, the airing racks are provided with airing main racks, the bottom ends of the airing main racks are provided with movable bases, the bottom ends of the movable bases are provided with movable wheels, the two sides of the movable bases are provided with base supports, an elastic base is arranged on one side of each movable base, a penetrating hole is formed in the center of the top end of each elastic base, a special-shaped brake rod is arranged in each penetrating hole, a special-shaped sliding groove is formed in the center of each airing main rack, the overturning main body comprises an overturning structure and a balance structure, the balance structure is arranged between a side overrunning body and the special-shaped sliding grooves in a penetrating mode, and the brake structure is arranged on one side of the top ends of the movable bases. The device has the advantages that an airing rope can move upwards by the distance of a plurality of chain pieces at a time, stooping work of people is reduced, the grape airing efficiency is improved, raisins can be collected in a unified mode, the trouble caused by building of an airing shed is reduced, and the grape bunch placing efficiency is effectively guaranteed.

Owner:濉溪初新工业设计有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com