Sr and Mg doped amorphous apatite material and crystalline apatite material

A technology of element doping and apatite, which is applied in the field of biomedical materials, can solve the problems of unfavorable new bone growth and poor biological activity of artificial bone scaffolds, and achieve the effect of high affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Raw materials and requirements: Ca(NO 3 ) 2 (analytical pure), (NH 4 ) 2 HPO 4 (analytical pure) and NH 3 ·H 2 O (analytically pure).

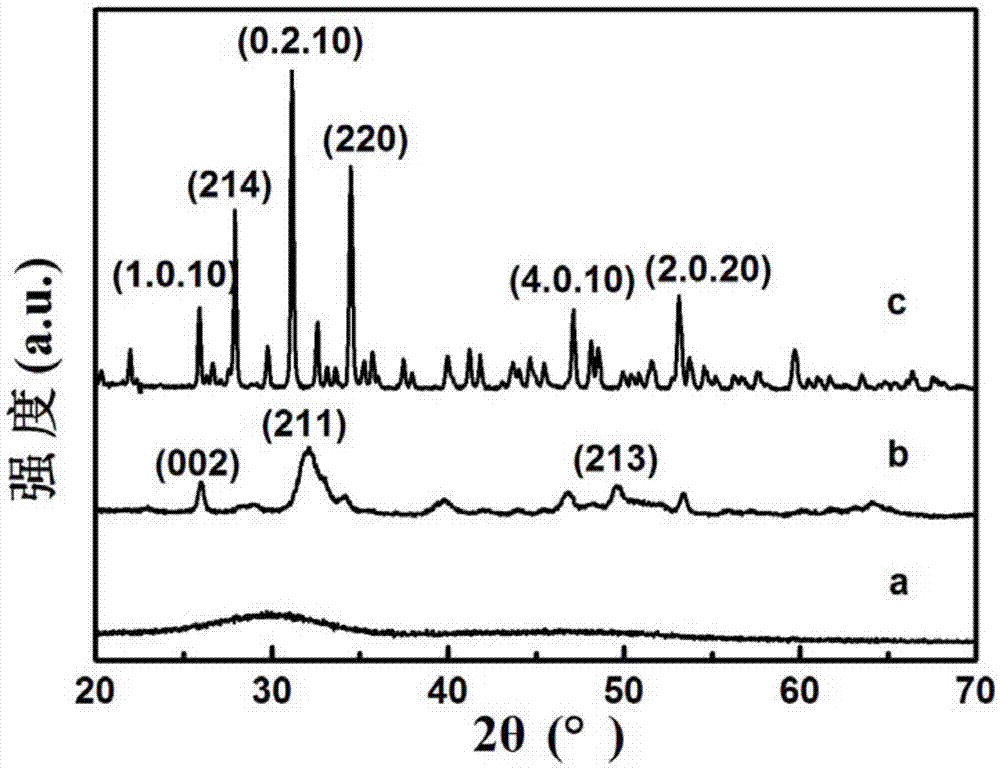

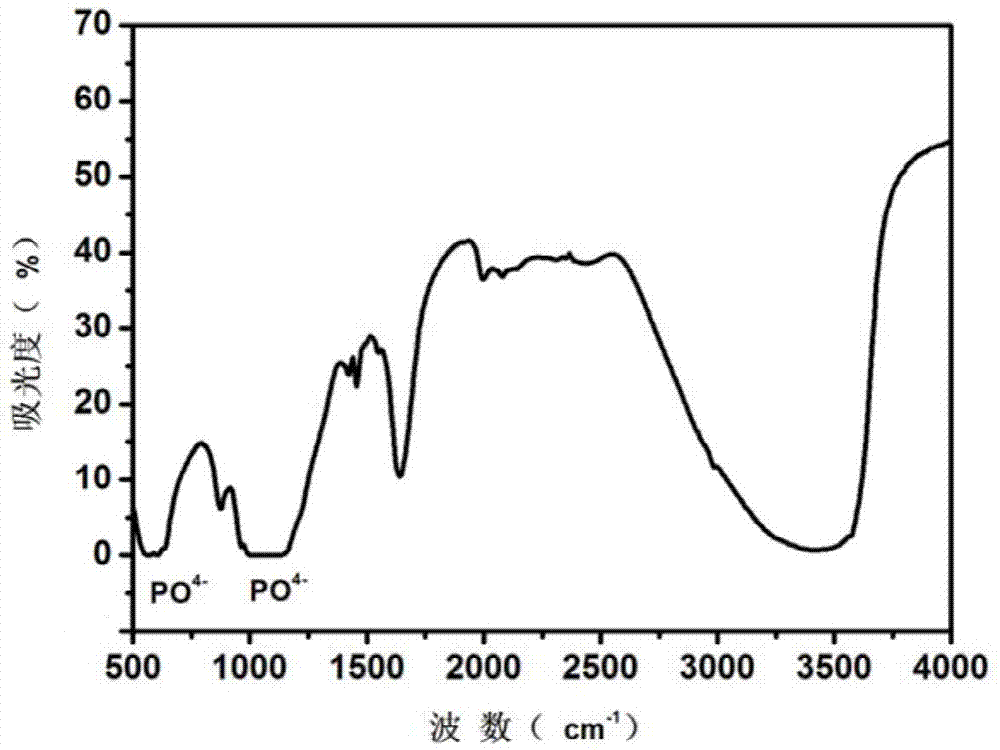

[0046] Rapid precipitation: 0.09mol of Ca(NO 3 ) 2 Dissolve in 1L deionized water to obtain solution A(Ca(NO 3 ) 2 Concentration is 0.09mol / L), with magnetic stirring 5min (500rpm), 0.06mol of (NH 4 ) 2 HPO 4 Dissolved in 1L deionized water to obtain solution B ((NH 4 ) 2 HPO 4 Concentration is 0.06mol / L), with magnetic stirring 5min (500rpm), the pH value of these two kinds of solutions is adjusted to 9-10 with the ammonia solution (analytical grade) of 25% by mass percent, then solution A is poured into solution rapidly In B, stir magnetically for 30s (500rpm), filter with a suction filter bottle, and wash with deionized water and alcohol three times respectively to obtain a milky white material. Freeze-dried for 24 hours to obtain non-doped amorphous apatite powder [Ca9(HPO 4 )(PO 4 ) 5 (OH)]( figure 1 (a), figu...

Embodiment 2

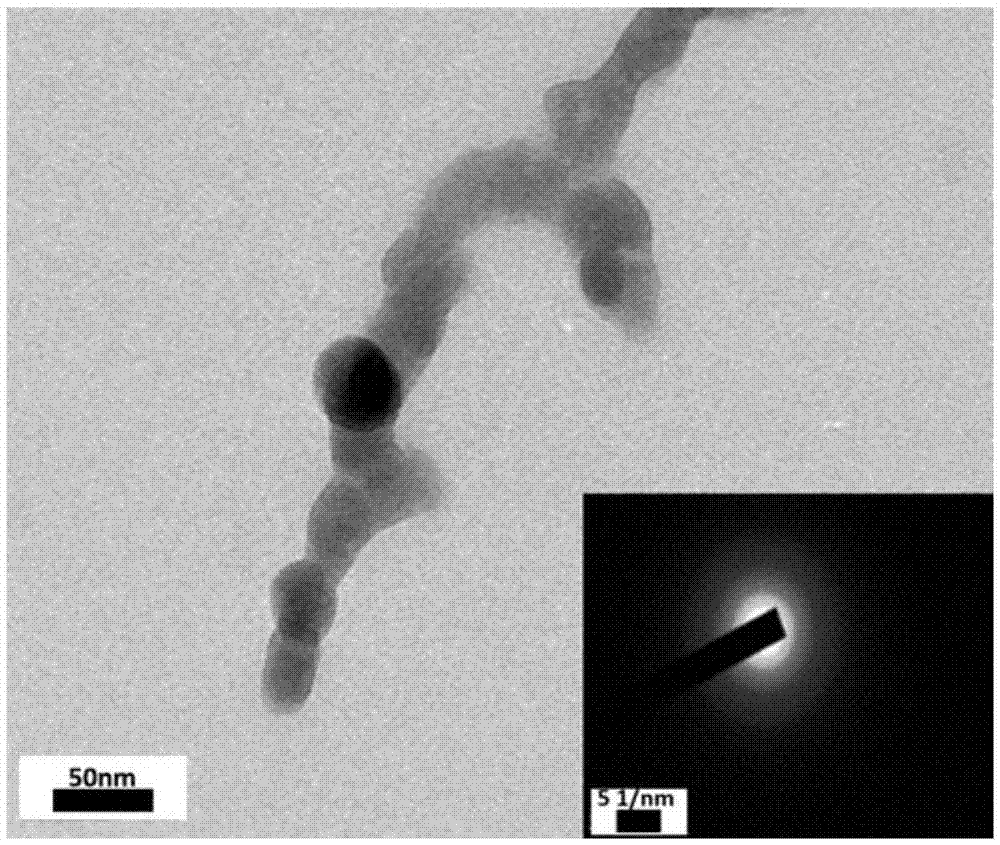

[0049] In this example, 0.0772mol of Ca(NO 3 ) 2 and 0.0128mol of Mg(NO 3 ) 2 Dissolve in 1L deionized water to obtain solution A(Ca(NO 3 ) 2 The concentration is 0.0772mol / L, Mg(NO 3 ) 2 Concentration is 0.0128mol / L), all the other parts are identical with embodiment 1, lyophilized 24 hours, obtain the (Mg / (Ca+Mg)=14.25%) amorphous apatite powder ( image 3 ). Carry out heat treatment in heat treatment furnace 800 ℃ for 3 hours to obtain the β-TCP crystal material ( Figure 5 (e)).

Embodiment 3

[0051] In this example, 0.0813mol of Ca(NO 3 ) 2 and 0.0087mol of Mg(NO 3 ) 2 Dissolve in 1L deionized water to obtain solution A(Ca(NO 3 ) 2 The concentration is 0.0813mol / L, Mg(NO 3 ) 2The concentration is 0.0087 mol / L), and the rest is the same as in Example 1, and freeze-dried for 24 hours to obtain amorphous apatite powder doped with 9.67% Mg molar percentage (Mg / (Ca+Mg)=9.67%). Carry out heat treatment at 120 ℃ in the heat treatment furnace for 3 hours to obtain the nano calcium-deficient hydroxyapatite crystal material ( Figure 4 (b)).

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com