Method for synthesizing selenium and bismuth selenide nano material by using lysinibacillus sp.

A technology of Bacillus lysinus and nanomaterials, applied in the field of environmental nanobiology, can solve the problems of no biological synthesis of bismuth selenide and no biosynthesis of bismuth selenide, and achieve easy expansion and cultivation, simple operation, and environmental protection. green friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

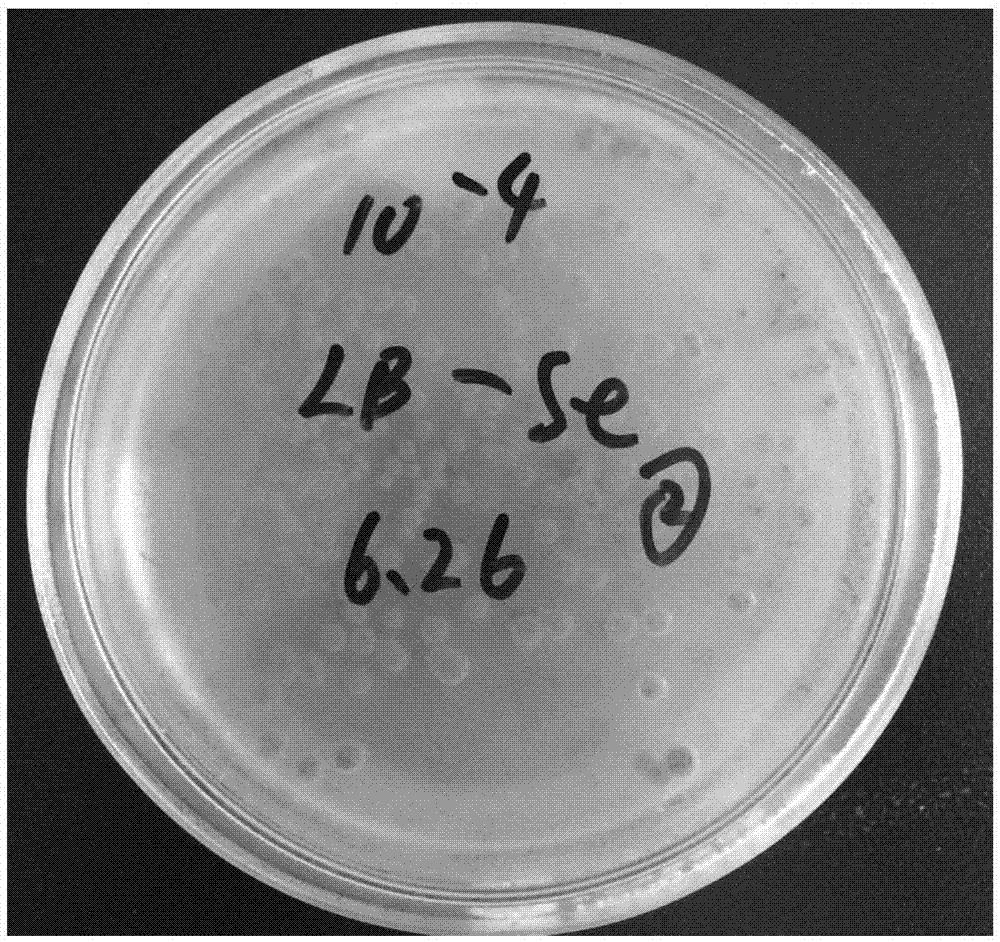

[0026] Example 1: Under plate coating culture conditions, strain ZYM-1 reduces selenite to synthesize selenium nanoparticles

[0027] Reaction system: After diluting the ZYM-1 bacterial solution in 20ml of LB liquid medium containing 0.5-25mM (mmol) sodium selenite for 8-12 hours to different times, spread it evenly on the surface containing 1 mM sodium selenite on LB solid medium. Incubate for 36 h in a constant temperature incubator at 30°C. The color of the colony changed from light yellow to red, revealing the generation of the reduction product selenium nanoparticles, and the photos of the cultivated plates were as follows: figure 1 shown.

Embodiment 2

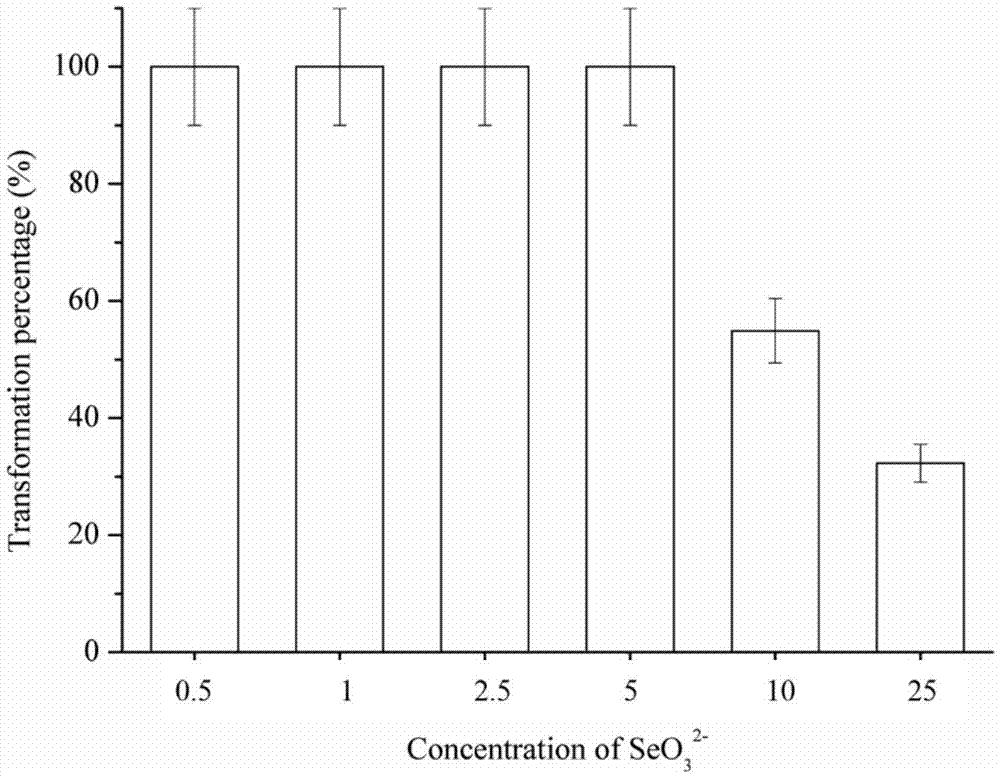

[0028] Example 2: The reduction degree of bacterial strain ZYM-1 to selenite under different sodium selenite concentrations

[0029] Add 0.5, 1, 2.5, 5, 10, and 25 mM sodium selenite to 20 mL of liquid LB medium respectively, and the inoculum amount of ZYM-1 bacteria solution is 1%, and the culture temperature is 30 ° C, pH is 5.5, 100 rpm Cultivate for 48 hours; the composition of the LB liquid medium is: sodium chloride 10g / L, peptone 10g / L, yeast powder 5g / L. The generated elemental selenium nanoparticles were treated with Na 2 S oxidation, calculation of selenium content, the specific method is as follows:

[0030] 1. Prepare 1M Na 2 S solution, add an appropriate amount of NaOH solid to suppress Na 2Autohydrolysis of S. Prepare 1M NaCl solution. Add different amounts of commercial selenium powder into 10ml test tubes, add 5mLNa 2 The S solution was fully shaken and dissolved so that the concentrations of selenium in the standard solution were 0.5, 1, 2, 3, 4, 5 mM r...

Embodiment 3

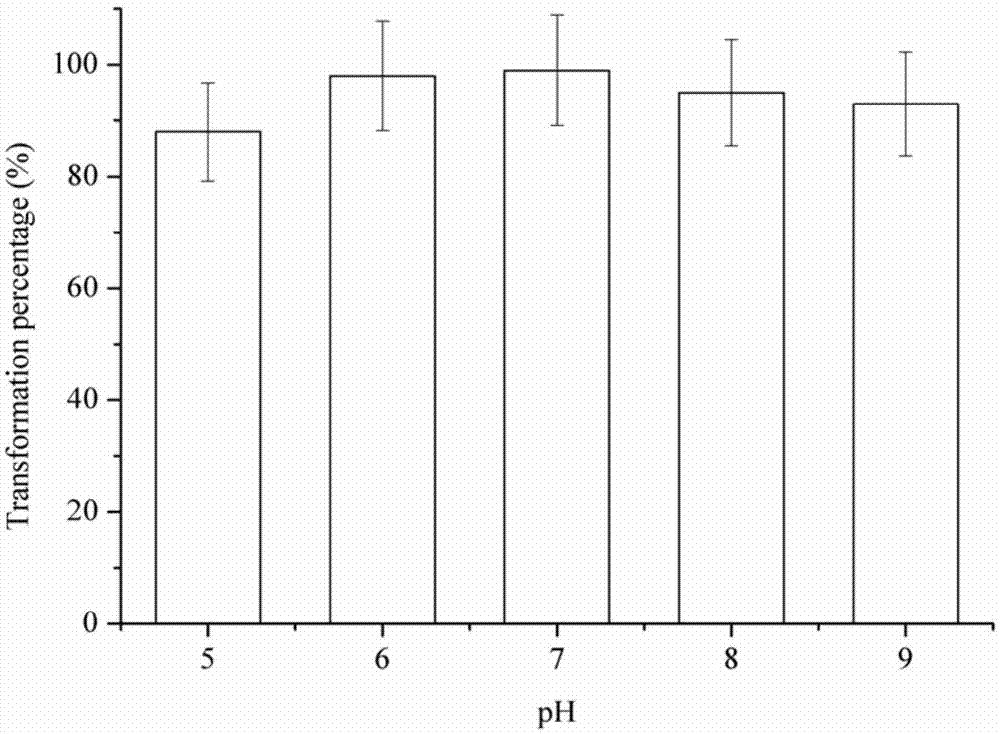

[0032] Example 3: Effects of different pH on reduction of selenite by bacterial strains.

[0033] Use HCl or NaOH to adjust the pH of the liquid LB medium to 4, 5, 6, 7, 8, 9, 10, 11, respectively, and ensure that the total volume of the culture system is 20 mL. The inoculation amount of the bacterial liquid ZYM-1 was 1%, the concentration of selenite was 5mM, the culture temperature was 30°C, and 200rpm was cultivated for 36h; the composition of the LB liquid medium was: sodium chloride 10g / L, peptone 10g / L, yeast Powder 5g / L. Utilize Na 2 The elemental selenium nanoparticles generated by S oxidation, the specific measurement method is as follows:

[0034] The sample containing bacteria and intracellular selenium nanoparticles was centrifuged at 10000rpm for 10min and separated from the supernatant. Rinse 2 times with 1M NaCl solution to remove residual selenite in the solution, and then wash the residual solid with 5mL of 1M NaCl 2 S was fully shaken to dissolve, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com