Preparation method of L-tyrosine

A tyrosine and supercritical technology, which is applied in the field of L-tyrosine preparation, can solve the problems that the extraction method needs to be improved and the extraction effect needs to be improved, so as to achieve high extraction capacity and separation efficiency, improve stripping efficiency, and water-soluble good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

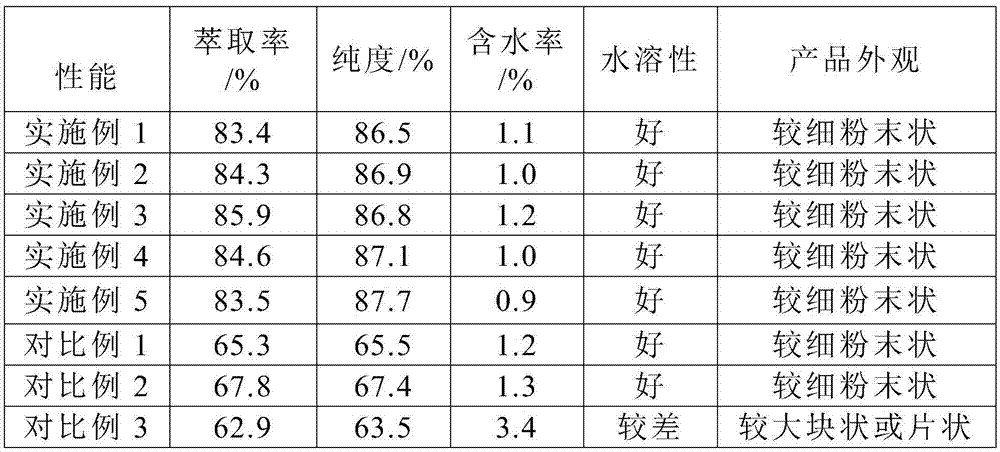

Examples

Embodiment 1

[0036] A preparation method of L-tyrosine, comprising the steps of:

[0037] Brevibacteria are inoculated on the medium, fermented and cultured to obtain a fermented liquid, the fermented liquid is centrifuged and ultrafiltered to obtain an ultrafiltrate, the ultrafiltration molecular weight cut-off is 1000-2000, the pH value of the ultrafiltrate is adjusted to 4.5, and NaCl is added to adjust The ionic strength is up to 0.30mol / L.

[0038] Add NaCl, buffer disodium hydrogen phosphate-citric acid, and 2.0% w / v porous silica gel to pure water to make a buffer solution with a pH value of 9.0 and an ionic strength of 1.4 mol / L, that is, back extraction water phase solution.

[0039] Add ultrafiltrate, surfactant and THF accounting for 13% v / v of surfactant into a supercritical extractor for supercritical extraction. The surfactant is a mixture of AOT and DTDPA with a molar ratio of 6:3. Surfactants and CO in supercritical extractors 2 Supercritical fluid forms supercritical fl...

Embodiment 2

[0042] A preparation method of L-tyrosine, comprising the steps of:

[0043] Inoculate the Brevibacterium on the culture medium, ferment and cultivate to obtain the fermentation liquid, centrifuge the fermentation liquid, and ultrafilter to obtain the ultrafiltrate, the ultrafiltration molecular weight cut-off is 1000-2000, adjust the pH value of the ultrafiltrate to 4.2, and add KCl to adjust The ionic strength is up to 0.23mol / L.

[0044] Prepare the stripping aqueous phase solution, add KCl, buffering agent citric acid-sodium citrate, and 0.5% w / v porous silica gel to pure water to make a buffer with a pH value of 8.5 and an ionic strength of 1.2 mol / L solution, that is, stripping the aqueous phase solution.

[0045] Add the ultrafiltrate, surfactant and THF accounting for 10% v / v of the surfactant into the supercritical extractor for supercritical extraction. The surfactant is a mixture of AOT and DTDPA with a molar ratio of 4:3. Surfactants and CO in supercritical extra...

Embodiment 3

[0048] A preparation method of L-tyrosine, comprising the steps of:

[0049] Brevibacteria are inoculated on the medium, fermented and cultivated to obtain a fermented liquid, the fermented liquid is centrifuged and ultrafiltered to obtain an ultrafiltrate, the ultrafiltration molecular weight cut-off is 1000-2000, the pH value of the ultrafiltrate is adjusted to 5.0, and NaCl is added to adjust The ionic strength is up to 0.35mol / L.

[0050] Prepare the back extraction aqueous phase solution, add KCl, buffer acetic acid-sodium acetate, and 4.0% w / v porous silica gel to pure water to make a buffer solution with a pH value of 9.0 and an ionic strength of 1.6 mol / L, That is, stripping the aqueous phase solution.

[0051] Add ultrafiltrate, surfactant and THF accounting for 15% v / v of surfactant into a supercritical extractor for supercritical extraction. The surfactant is a mixture of AOT and DTDPA with a molar ratio of 7:3. Surfactants and CO in supercritical extractors 2 Su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| ionic strength | aaaaa | aaaaa |

| ionic strength | aaaaa | aaaaa |

| ionic strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com