Clutch face plate for heavy goods vehicle

A technology for clutch facings and trucks, which is applied in clutches, friction clutches, mechanically driven clutches, etc., and can solve the problem of reduced selectivity of frictional working layer components and formulas, difficulty in meeting performance indicators, balance of cost and application, and difficult performance of clutches. Index and other issues, to achieve the effect of reduced thermal recession index, good toughness, and reduced friction noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

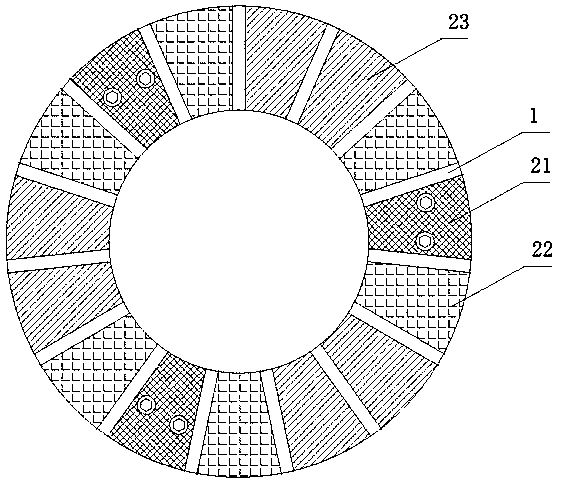

[0042] In terms of structure, such as figure 1 As shown, the clutch face sheet of the present invention is composed of a friction working layer and a structural layer 1. The structural layer 1 is formed in a ring shape, and its thickness is equal to the friction working layer; the friction working layer is staggered by friction linings of three different materials. Become. The friction linings of three different materials include a rubber-based friction lining 23, a rubber FA friction lining 22 and a ceramic fiber friction lining 21 with the same thickness.

[0043] Such as figure 1 As shown, the number of rubber-based friction linings 23 is six, the number of replacement FA friction linings 22 is six, and the number of ceramic fiber friction linings 21 is three; the three ceramic fiber friction linings 21 are regularly distributed at 120 degrees apart In the ring-shaped structural layer 1, each ceramic fiber friction lining 21 is equipped with rubber-replacement FA friction li...

Embodiment 2

[0072] The difference from the first embodiment is:

[0073] The present invention takes into account the limitation of the composition of the ceramic fiber friction lining 21. In the manufacturing process of the finished clutch face, the ceramic fiber friction lining 21 and the structural layer 1 are the most difficult to bond well, so it can be used in the ceramic fiber friction lining. There are recessed fixing through holes on 21, and the corresponding structural layer 1 is provided with mounting holes corresponding to the fixing through holes. The fasteners fix the ceramic fiber friction lining 21 to the structural layer through the fixing through holes and mounting holes. On 1, the fastener can be a hexagon socket bolt as shown in the figure.

Embodiment 3

[0075] The difference from the first embodiment is:

[0076] The rubber raw material consists of the following parts by weight: 12 parts of high nitrile nitrile rubber, 11 parts of carboxyl styrene butadiene latex, 3.5 parts of basic zinc carbonate, 0.5 part of accelerator DM, 0.4 part of antioxidant 1010, zonyl®FSA 0.2 parts of water-soluble carboxylate anionic fluorocarbon surfactant, 4 parts of calcium carbonate, 5 parts of talc, 9 parts of kaolin, 2 parts of dioctyl maleate, 6 parts of quartz powder, 0.4 parts of vulcanized powder, weight 11 parts of spar, 8 parts of emery, 16 parts of carbon black, 2 parts of alumina, 2 parts of cyclohexyl phthalate, 9 parts of aluminum hydroxide; go through the following steps:

[0077] a. Immerse the glass fiber bundle in the prepared water-soluble phenolic resin solution, and then pass the drying tower to dry it;

[0078] b. The tensioned glass fiber bundle is obtained by mechanical tensioning;

[0079] c. Put the above-mentioned rubber raw m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com