Preparation method of carbon-based quantum dot/nano-silver surface enhanced raman base

A surface-enhanced Raman and carbon-based quantum dot technology, applied in Raman scattering, measurement devices, instruments, etc., to achieve the effects of strong Raman signal, uniform size, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Weigh 20 mg of carbon-based quantum dots and 60 mg of silver nitrate and dissolve them in 50 mL of deionized water, then add 20 mg of sodium borohydride, the solution instantly turns black and viscous, and continues to stir for 30 minutes. After stopping the reaction, take out the solution in the beaker, centrifuge at a centrifugal force of 13000g for 5min, and repeat centrifugation and cleaning 5 times until the centrifugation supernatant is clear; Materials; store in the refrigerator at 4°C, away from light.

Embodiment 2

[0025] Weigh 200 mg of carbon-based quantum dots and 6 mg of silver nitrate and dissolve them in 50 mL of deionized water, then add 0.2 mg of sodium borohydride, the solution instantly turns black and viscous, and continues to stir for 5 hours. After stopping the reaction, take out the solution in the beaker, centrifuge for 30min under the centrifugal force of 7000g, and repeat the centrifugation and washing for 5 times until the centrifugation supernatant is clear. The obtained precipitate was dissolved in 10 mL of twice-distilled water to obtain a carbon-based quantum dot / nano-silver composite material. Store in the refrigerator at 4°C, away from light.

Embodiment 3

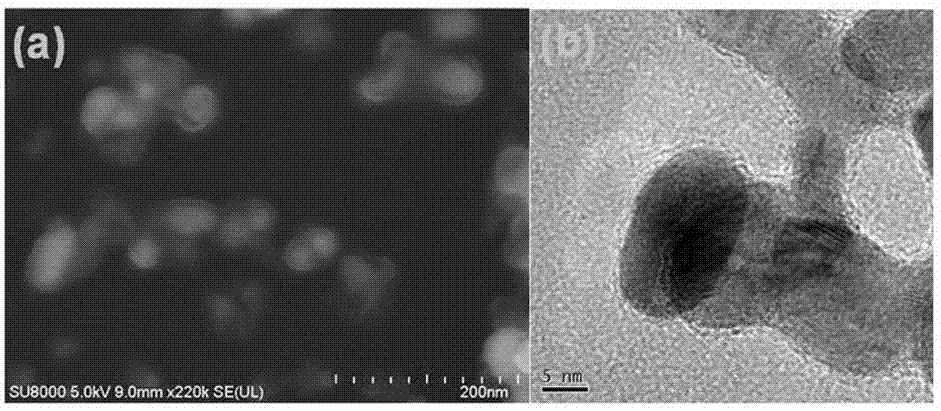

[0028] figure 1 Scanning electron micrograph (a) and transmission electron micrograph (b) of the prepared carbon-based quantum dots / nanosilver composite. figure 1 It shows that the silver nanoparticles prepared by this method are surrounded by a layer of carbon-based quantum dots with a thickness of about 1 to 2 nm, and the average particle size is about 20 nm.

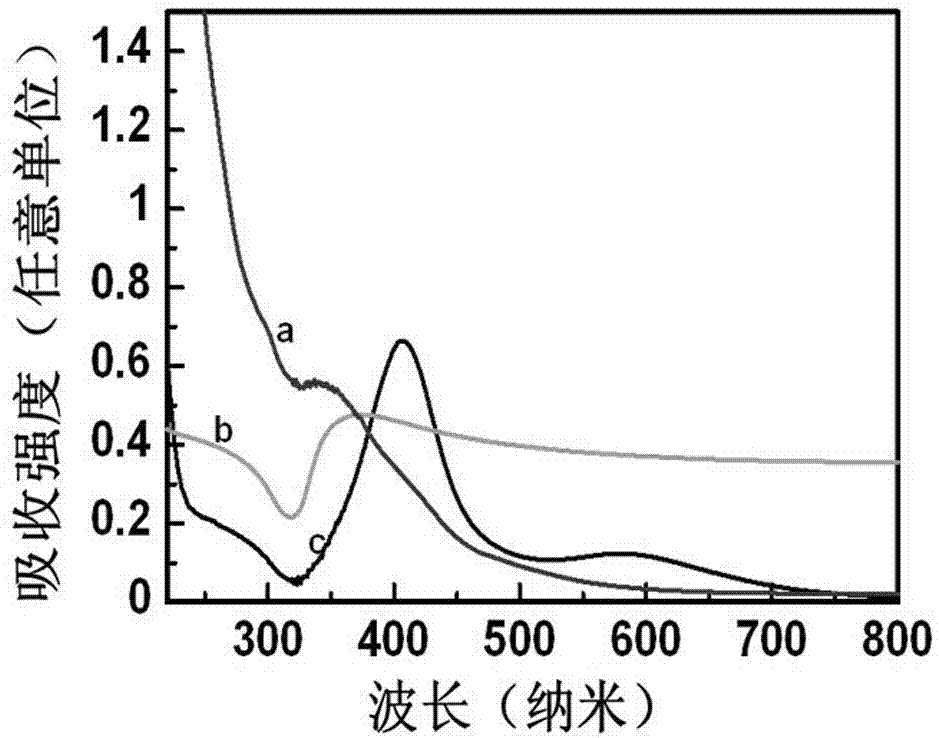

[0029] figure 2 The ultraviolet absorption peak of the carbon-based quantum dot / nano-silver composite material prepared for this method (a is the ultraviolet absorption peak of the carbon-based quantum dot; b is the ultraviolet absorption peak of the composite material itself; c is the ultraviolet absorption peak of the silver nanoparticle) . From figure 2 It can be seen that compared with carbon-based quantum dots and silver nanoparticles, the ultraviolet absorption peak of the carbon-based quantum dot / nano-silver composite material has a broad ultraviolet absorption peak between 320nm and 500nm. Combined w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Scale | aaaaa | aaaaa |

| Scale | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com