Novel three-dimensional electrode material for lithium air battery and preparation method for novel three-dimensional electrode material

A lithium-air battery and three-dimensional electrode technology, applied in battery electrodes, nanotechnology for materials and surface science, circuits, etc., can solve problems such as energy loss, porosity reduction, oxygen channel blockage, etc., to save the preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A piece of carbon paper with a size of 2*5cm and a mass of 44.6mg was anodized in dilute sulfuric acid for 3 minutes, in which the carbon paper was used as the anode and the titanium plate was used as the cathode, washed with deionized water, dried and put into NiCl 2 ·6H 2 Soak in ethanol solution of O for 5min, take it out and dry it at 80°C to get NiCl 2 / CFP.

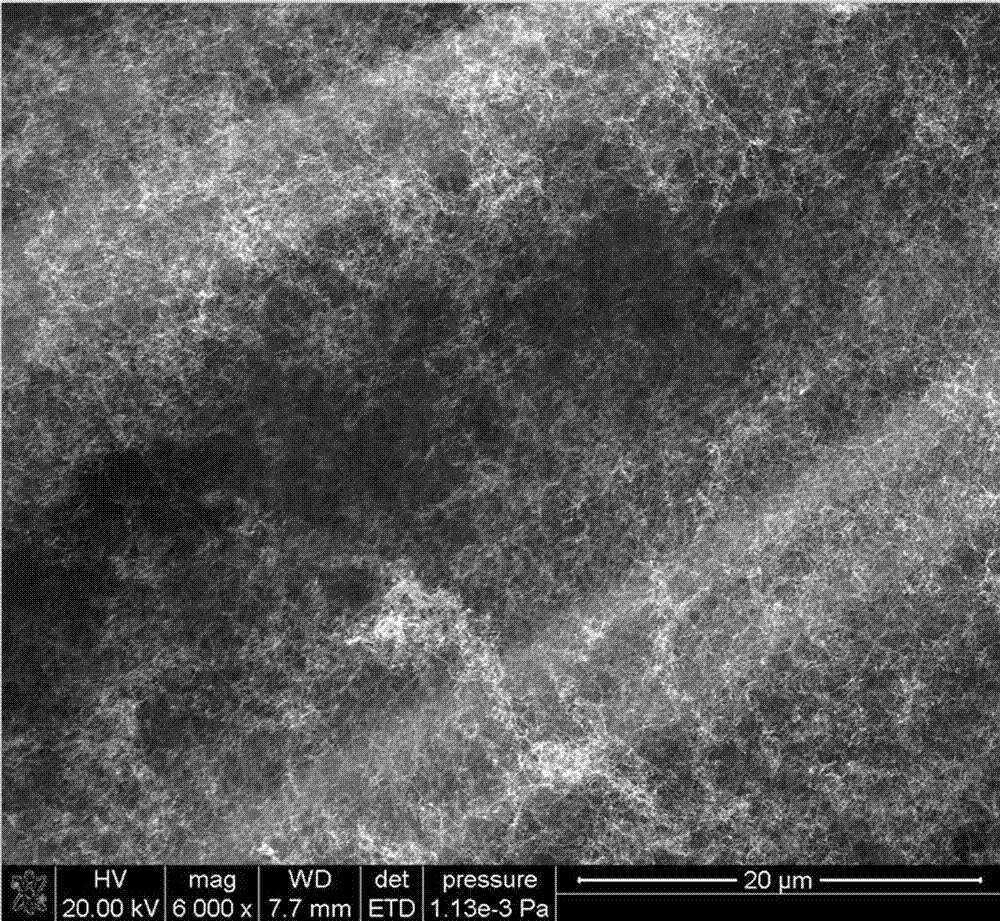

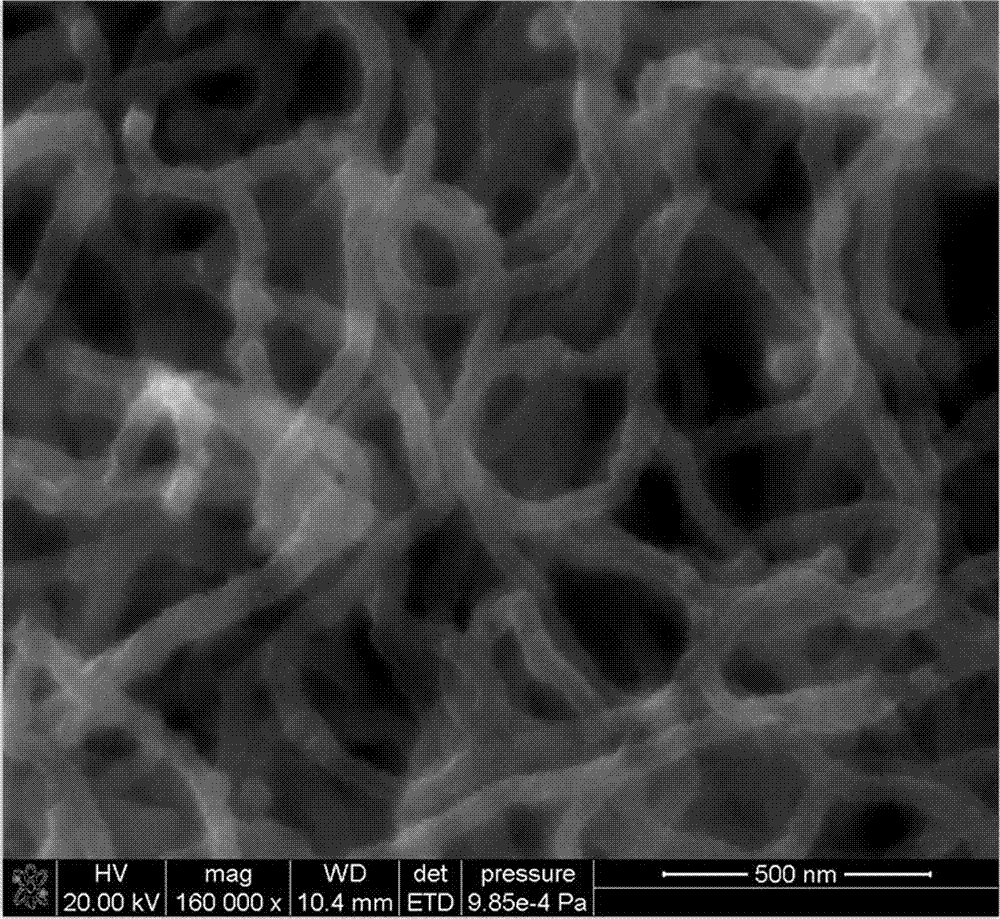

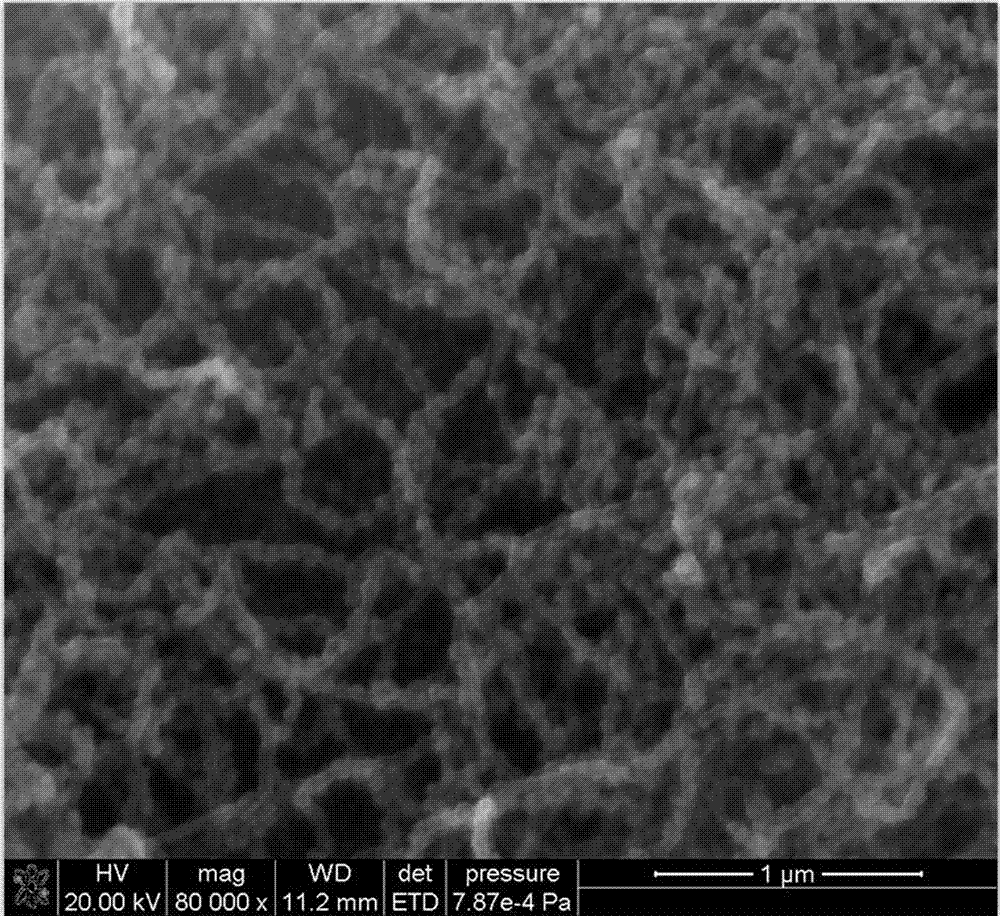

[0028] NiCl obtained above 2 / CFP is placed in a quartz reactor, and the temperature is raised at a heating rate of 10K / min. During the heating process, argon gas is introduced at a rate of 100mL / min as a protective gas, and ethylene is used as a carbon source. Argon, the rate of feeding is 200mL / min, after 20min, change to the mixed gas of hydrogen and argon, where hydrogen: argon = 8:5, the rate of passing the mixed gas is 130mL / min, after 40min in the argon atmosphere cooling down to room temperature naturally to obtain a multi-walled carbon nanotube / carbon paper three-dimensional composite material, th...

Embodiment 2

[0031] A piece of carbon paper with a size of 2*5cm and a mass of 45.5mg was anodized in dilute sulfuric acid for 3 minutes, in which the carbon paper was used as the anode and the titanium plate was used as the cathode, washed with deionized water, dried and put into NiCl 2 ·6H 2 Soak in ethanol solution of O for 5min, take it out and dry it at 80°C to get NiCl 2 / CFP.

[0032] NiCl obtained above 2 / CFP is placed in a quartz reactor, and the temperature is raised at a heating rate of 10K / min. During the heating process, argon gas is introduced at a rate of 100mL / min as a protective gas, and ethylene is used as a carbon source. Argon, the rate of feeding is 200mL / min, after 20min, change to the mixed gas of hydrogen and argon, where hydrogen: argon = 8:5, the rate of passing the mixed gas is 130mL / min, after 40min in the argon atmosphere Naturally cooling to room temperature, the multi-walled carbon nanotube / carbon paper three-dimensional composite material is obtained, an...

Embodiment 3

[0035] A piece of carbon paper with a size of 2*5cm and a mass of 45.3mg was anodized in dilute sulfuric acid for 3 minutes, in which the carbon paper was used as the anode and the titanium plate was used as the cathode, washed with deionized water, dried and put into NiCl 2 ·6H 2 Soak in ethanol solution of O for 5min, take it out and dry it at 80°C to get NiCl 2 / CFP.

[0036] NiCl obtained above 2 / CFP is placed in a quartz reactor, and the temperature is raised at a heating rate of 10K / min. During the heating process, argon gas is introduced at a rate of 100mL / min as a protective gas, and ethylene is used as a carbon source. Argon, the rate of feeding is 200mL / min, after 20min, change to the mixed gas of hydrogen and argon, where hydrogen: argon = 8:5, the rate of passing the mixed gas is 130mL / min, after 40min in the argon atmosphere Naturally cooling to room temperature, the multi-walled carbon nanotube / carbon paper three-dimensional composite material is obtained, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com