High toughness and abrasion resistant PVC resin cable material and preparation method thereof

A PVC resin and cable material technology, applied in the direction of plastic/resin/wax insulators, organic insulators, etc., can solve the problems of not resistant to scratches and folding, poor flame retardant performance, not resistant to humidity, cold and heat, etc., to achieve fine surface and wear resistance , Improved processing performance, good chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

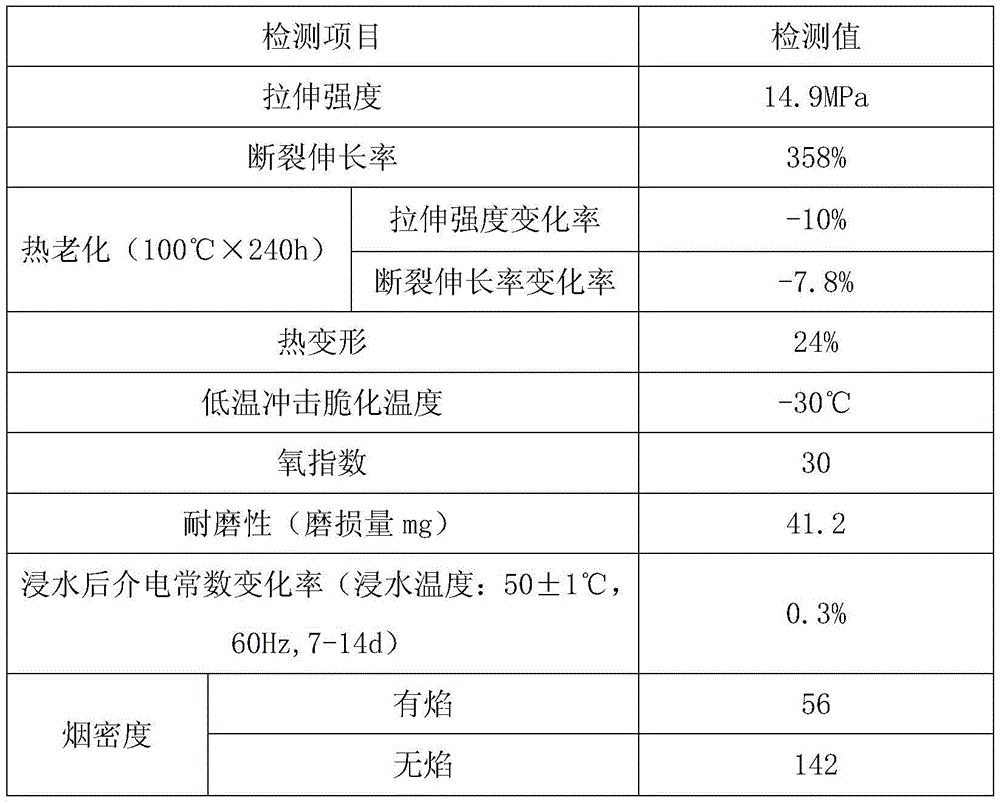

Examples

Embodiment

[0012] The cable material of this embodiment is made of the following raw materials in parts by weight: cerium oxide 0.2, tetraethyl orthosilicate 5, calcium-based bentonite 25, stannous pyrophosphate 2, zinc stearate 3, PVC resin 60, polyethylene Wax 8, coumarone 3, isotactic polypropylene 20, trioctyl trimellitate 12, color masterbatch 8, aluminum hydroxide 18, polytetrafluoroethylene powder 6, additive 3.

[0013] The auxiliary agent is made of the following raw materials in parts by weight: absolute ethanol 8, aluminum nitride powder 15, zinc stannate 3, vinyl silane coupling agent 2, triethanolamine borate 3, the preparation method is: first Mix and disperse zinc stannate, vinyl silane coupling agent, triethanolamine borate and absolute ethanol evenly, then put aluminum nitride powder into the mixed solution, grind and disperse for 30 minutes, dry the powder at room temperature, remove anhydrous Ethanol, additives.

[0014] Described a kind of high toughness wear-resisti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com