Composite membrane for in-situ simultaneous monitoring of labile phosphorus and dissolved oxygen and preparation method thereof

A composite membrane, active phosphorus technology, applied in measurement devices, fluorescence/phosphorescence, instruments, etc., can solve problems that have not been reported in public, and achieve the effect of optimal machinery and high phosphorus adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

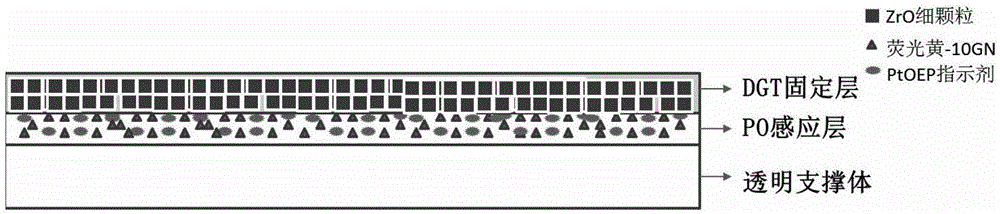

[0028] A DGT-PO composite membrane for in-situ simultaneous monitoring of active phosphorus and dissolved oxygen and its preparation, using the following methods:

[0029] (1) Take 10mg, 10mg, 500mg of PtOEP dye, fluorescent yellow 10-GN dye and polyethylene particles respectively, dissolve in 10mL of toluene, after ultrasonic dissolution, take 200μL of the mixed solution, and use the method of 100μm scraping film to mix the The solution was uniformly coated on a transparent PET film substrate, and after drying at room temperature for 30 minutes, the fluorescent sensing layer (PO) of the composite film was formed; it was stored in a dark place away from light and sealed until use.

[0030] (2) Prepare submicron ZrO ultrafine particle slurry according to the method described by Kreuzeder, A, etc.; weigh the ultrafine particle slurry containing 8.0g ZrO, and then mix it with 16mL of polyurethane hydrogel HYD4 (polyurethanehydrogel, typeD4, purchased from AdvanSource Biomaterials, U...

Embodiment 2

[0034] Test the DGT-PO composite membrane of the present invention to the fixing performance of phosphorus, carry out according to the following steps:

[0035] (1) Prepare the DGT-PO composite membrane according to Example 1, then place the composite membrane in denitrogenated, ultrapure water for at least 4 hours and set aside for later use.

[0036] (2) The composite membrane treated in step (1) is cut with a stainless steel circular cutter to obtain a composite membrane disc with a diameter of 2.5 cm, and the obtained composite membrane disc and 0.45 μm filter membrane are stacked in sequence and assembled into a DGT device.

[0037] (3) Put the DGT device assembled in step (2) into deionized water and perform nitrogen filling for 12 hours to remove oxygen (to exclude the influence of DO on the PO layer).

[0038] (4) Put the DGT device in step (3) into 1mg / L phosphate-containing mother liquor (pH=7.0±0.2; 0.03MNaCl)), place 2, 4, 6, 8, 12, 16, 22 , After 24 hours, the a...

Embodiment 3

[0040] Test the DGT-PO composite membrane of the present invention to the fixed capacity of phosphorus, concrete steps are as follows:

[0041] (1) The composite membrane disc obtained in step (2) in Example 2 was put into deionized water, and inflated with pure nitrogen for 12 hours to remove the oxygen in the membrane, and set aside.

[0042] (2) The obtained composite membrane disc and the 0.45 μm filter membrane are sequentially stacked and then assembled into a DGT device.

[0043] (3) Put the DGT device assembled in step (2) into 8 different phosphate-containing mother solutions of 0.5-10mg / L (0.001mgP / L-20mgP / L, pH=7.0±0.2; 0.03MNaCl) , for 6h adsorption, and each group had 3 parallel samples.

[0044] (4) After the adsorption is completed, take out the DGT device, recover the composite membrane, then rinse with ultrapure water and put it into 5mL 1.0M NaOH solution for 24h to fully extract, and then use microcolorimetry to measure the phosphorus concentration in the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com