A kind of silicon carbon composite negative electrode material and preparation method thereof

A negative electrode material and silicon-carbon composite technology, which is applied in the preparation/purification of carbon, battery electrodes, electrical components, etc., can solve the problems of cycle performance degradation and function reduction, and achieve the effect of improving performance and reducing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

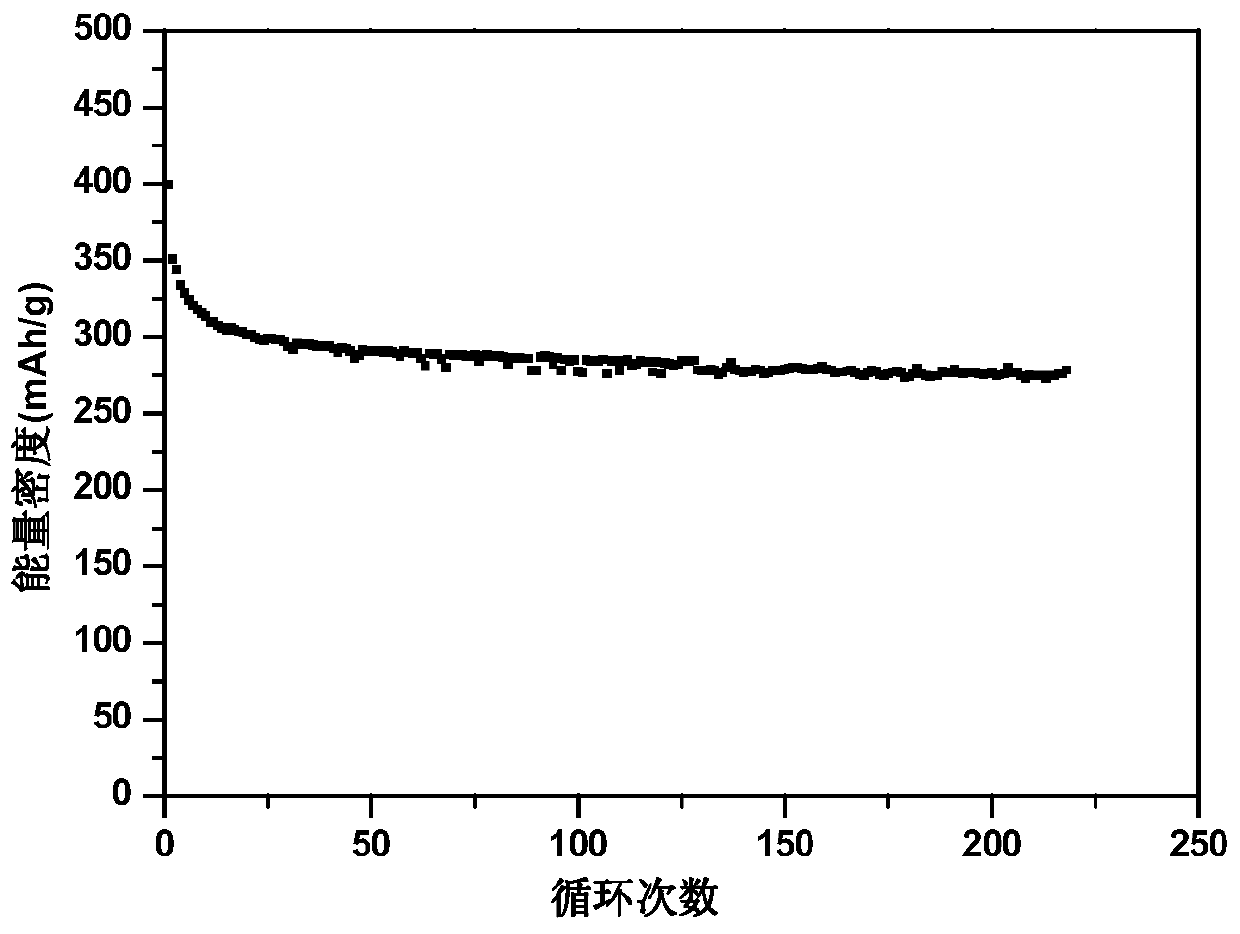

Embodiment 1

[0037] Dissolve 95.232g of naphthalene in 500ml of ethylene glycol dimethyl ether, add 20.5356g of sodium block, and dissolve into a green-black solution. Stirring overnight, then 30.35g SiCl 4 It was added to the above green-black solution and stirred vigorously for 4 hours. Subsequently, the ethylene glycol dimethyl ether solution in which 25.29 g of polyvinyl butyral was dissolved was added to the suspension, and stirred for 2 h. Distill under reduced pressure to remove ethylene glycol dimethyl ether, then add cyclohexane to remove naphthalene. A tan solid was obtained. The above solid was raised to 800°C at a heating rate of 5 minutes and kept at 5 hours, then cooled naturally. Take out and wash away the sodium chloride in the product with distilled water, and dry to obtain the final product.

Embodiment 2

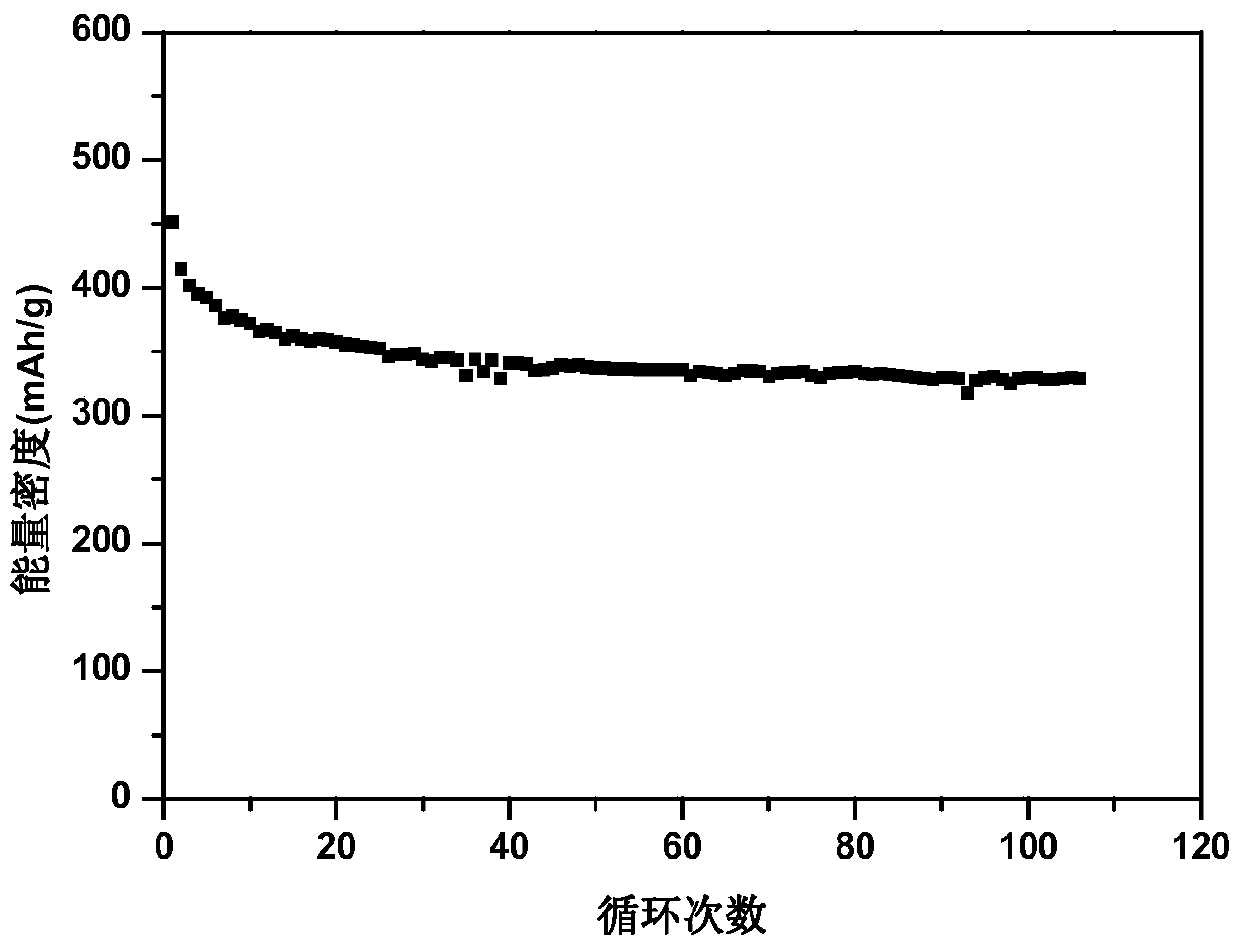

[0039] Dissolve 95.232g of naphthalene in 500ml of ethylene glycol dimethyl ether, add 20.5356g of sodium block, and dissolve into a green-black solution. After stirring overnight, 30.35 g of SiCl4 was added to the above green-black solution and stirred vigorously for 4 hours. Subsequently, the ethylene glycol dimethyl ether solution in which 8.56 g of phenolic resin was dissolved was added to the suspension, and stirred for 2 h. Distill under reduced pressure to remove ethylene glycol dimethyl ether, then add cyclohexane to remove naphthalene. A tan solid was obtained. The above-mentioned solid was raised to 450°C at a heating rate of 2°C / min and kept at 5 hours, then cooled naturally. Take out and wash away the sodium chloride in the product with distilled water, and dry it. Take 4.0 g of the above-mentioned product, add it into deionized water together with 0.4 g of polyethyleneimine, grind it with a planetary ball for 1.5 hours, and spray dry it. The obtained material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com