Hydrotreatment catalyst and application thereof

A hydrogenation treatment and catalyst technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, organic compound/hydride/coordination complex catalysts, etc., can solve the problem of low reaction performance problem, to achieve high hydrodesulfurization activity and performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Weigh 900.0 grams of Changling dry rubber powder, mix it with 898 ml of 1% nitric acid aqueous solution, knead it into a plastic body on a twin-screw extruder, extrude it into a clover-shaped strip of ф1.6 mm, and dry it at 120 ° C for 3 hours , take 300 grams of dried strips and bake them at 700°C for 3 hours to obtain S 1 carrier.

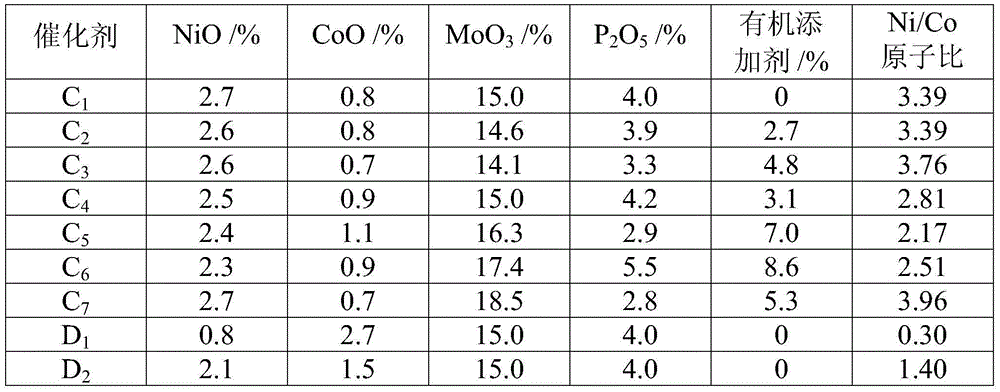

[0039] Weigh S 1 Carrier 100.0 g, impregnated with 95 ml of aqueous solution containing 6.8 g of basic nickel carbonate, 1.8 g of basic cobalt carbonate, 19.4 g of molybdenum trioxide and 7.1 g of phosphoric acid for 2 hours, dried at 120°C for 2 hours, and calcined at 550°C for 2 hours to obtain Catalyst C 1 . Catalyst C 1 NiO, CoO, MoO in 3 and P 2 o 5 See Table 1 for weight content, atomic ratio of nickel and cobalt.

Embodiment 2

[0041] Weigh S 1 100.0 g of carrier was impregnated with 95 ml of aqueous solution containing 6.8 g of basic nickel carbonate, 1.8 g of basic cobalt carbonate, 19.4 g of molybdenum trioxide and 7.1 g of phosphoric acid for 2 hours, dried at 120°C for 2 hours, and calcined at 550°C for 2 hours. After being cooled to room temperature, continue to impregnate with the aqueous solution containing 68 milliliters and 3.6 grams of glycerol for 2 hours, and dry at 150° C. for 2 hours to obtain catalyst C 2 . Catalyst C 2 NiO, CoO, MoO in 3 ,P 2 o 5 See Table 1 for the weight content of organic additives and the atomic ratio of nickel and cobalt.

Embodiment 3

[0043] Take by weighing 300 grams of dried bars in Example 1, and bake them at 600° C. for 6 hours to obtain S 2 . Carrier.

[0044] Weigh S 2 100.0 g of the carrier was impregnated with 95 ml of aqueous solution containing 6.7 g of phosphoric acid for 2 hours, dried at 110° C. for 6 hours, and calcined at 420° C. for 4 hours. Then impregnate 1.5 hours with 92 milliliters of aqueous solutions containing 15.6 grams of nickel nitrate, 4.1 grams of cobalt nitrate, 25.9 grams of ammonium paramolybdate and 7.2 grams of aminotriacetic acid, and dry at 180° C. for 4 hours to obtain catalyst C 3 . Catalyst C 3 NiO, CoO, MoO in 3 ,P 2 o 5 See Table 1 for the weight content of organic additives and the atomic ratio of nickel and cobalt.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com