Composition of scintillating glass for preparing scintillation fiber optic panels and its preparation method

A technology of scintillation glass and scintillation optical fiber, applied in glass manufacturing equipment, glass furnace equipment, optics, etc., can solve problems such as affecting the transmittance of ultraviolet and visible light of glass, sensitivity to light alkalinity of glass, affecting luminous intensity, etc., and achieve good application. Prospect, effect of excellent anti-devitrification performance and strong glass forming ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

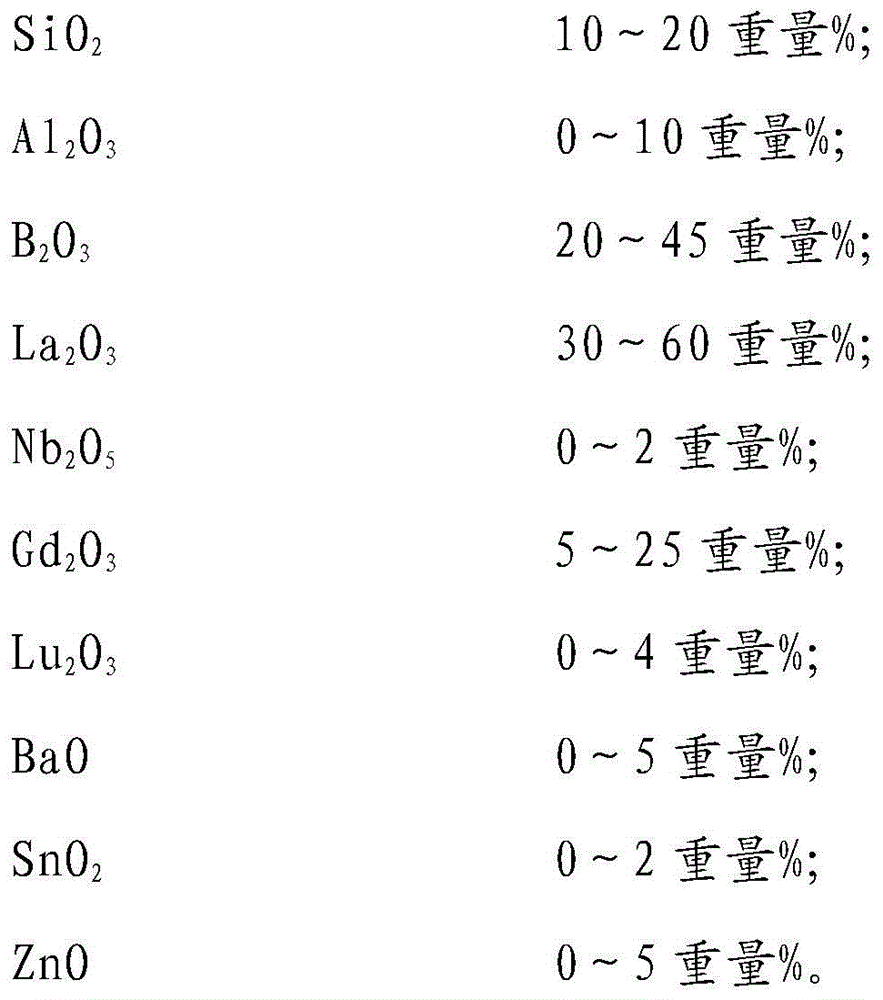

[0039] The invention provides a kind of scintillation glass for preparing scintillation optical fiber panels and a preparation method thereof, which consists of the following components by weight ratio:

[0040]

[0041] In the present invention, SiO 2 It is the main body of glass forming the skeleton and the main component of the glass skeleton. SiO 2If the content is less than 10% by weight, it is difficult to obtain glass with excellent optical properties, and at the same time it will reduce the chemical resistance of the glass; SiO 2 When the content is higher than 20% by weight, the high-temperature viscosity of the glass will increase, causing the glass melting temperature to be too high. Therefore, SiO 2 The percentage by weight of is 10-20 weight%, preferably 12-15 weight%.

[0042] Al 2 o 3 Intermediate oxides belonging to glass, Al 3+ There are two coordination states, which are located in tetrahedron or octahedron. When there is enough oxygen in the glass,...

Embodiment 1

[0065]First, select the raw materials according to the glass composition of Example 1 in Table 1, so that the ingredients meet the chemical composition of the glass in Table 1. After thorough mixing and grinding, the glass batch is prepared, and then poured into a platinum crucible, at a temperature of 1450 ° C. Melt in a glass melting furnace in a reducing atmosphere, directly pass the mixed gas of nitrogen and hydrogen into the crucible equipped with batch materials to obtain a reducing atmosphere, heat it for 8 hours after melting, and manually stir the glass liquid 3 times during the heat preservation period. Improve the melting quality and clarification quality of the glass liquid. After the glass batch is melted into a homogeneous glass melt, pour the glass melt into a heat-resistant steel mold with a size of 70mm×10mm×10mm preheated at 500°C and cast it into shape. , and then move the solidified glass sample to a muffle furnace at 600°C for annealing treatment. After 3 h...

Embodiment 2

[0067] Select raw materials according to the glass composition of Example 2 in Table 1, so that the ingredients meet the chemical composition of the glass in Table 1. After thorough mixing and grinding, the glass batch is prepared, then poured into a platinum crucible, and reduced with carbon monoxide at a temperature of 1400 ° C. It is melted in the glass melting furnace in the atmosphere, and the process of obtaining the carbon monoxide gas reducing atmosphere is to place a small crucible with carbon powder or graphite powder in the melting furnace for 2 hours to keep warm. After melting, heat preservation for 9 hours. During the heat preservation period, artificially stir the molten glass for 3 times to improve the melting quality and clarification quality of the glass liquid. After the glass batch material is melted into a homogeneous glass melt, pour the glass melt into the preheating Cast into a heat-resistant steel mold with a size of 70mm×10mm×10mm at 400°C, and then mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com