A method and device for synchronous oil production, carbon fixation, desulfurization, and denitrification using microalgae

A technology of microalgae and algae species, which is applied in the fields of bioenergy and environmental protection, and can solve the problems of high operating costs and inability to fully realize the economic and environmental benefits of cultivating oil-producing microalgae with industrial waste gas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] The method for synchronous oil production, carbon fixation, desulfurization and denitrification provided by microalgae provided by the present invention will be described in detail below in conjunction with specific examples.

[0088] A method for synchronous oil production, carbon fixation, desulfurization, and denitrification using microalgae, the steps of which are:

[0089] 1. Selection of microalgae species:

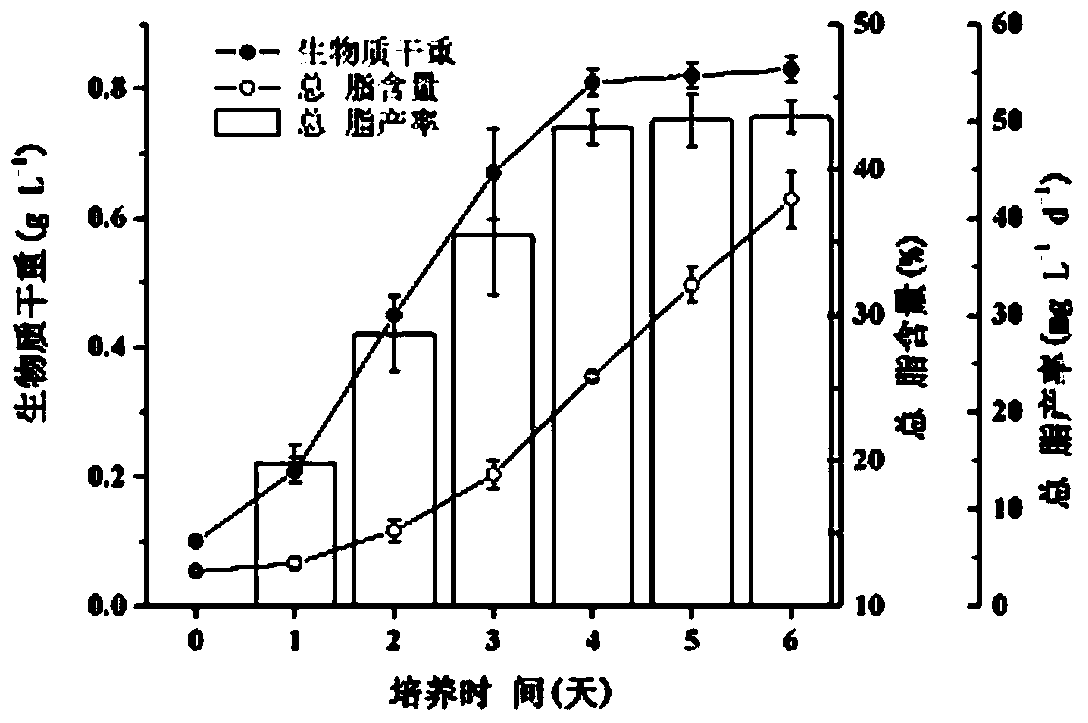

[0090] The selected microalgae is Chlorella pyrenoidosa, which is an excellent oleaginous microalgae selected from the Wuhan Botanical Garden of the Chinese Academy of Sciences (Liang et al., 2014. Chinese Journal of Oceanology and Limnology, 32, 1288-1296; Wen et al., 2014. Bioresource Technology, 161, 297-303; Wen et al., 2014. Fresenius Environmental Bulletin., 23, 2253-2258), capable of accumulating up to 55.0% of total lipids in cells. The microalgae here can also be selected from other oil-producing microalgae, and the effect may not be as good as Chlo...

Embodiment 2

[0156] The device for synchronous oil production, carbon fixation, desulfurization and denitrification provided by microalgae provided by the present invention will be specifically described below in conjunction with specific drawings.

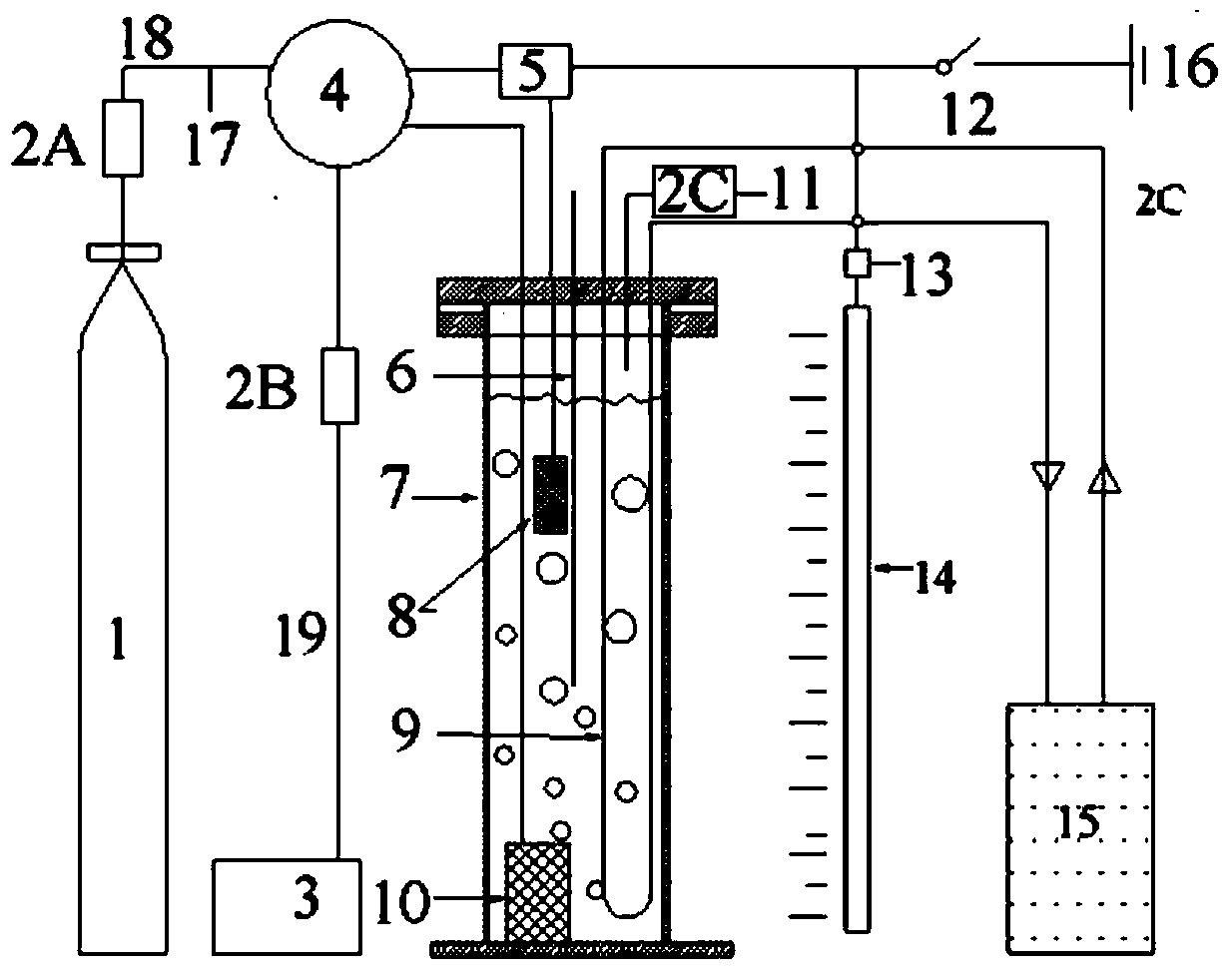

[0157] The device provided by the present invention utilizes microalgae to simultaneously produce oil, fix carbon, desulfurize, and remove nitrate, such as figure 1 As shown, the device includes a photobioreactor 7, an illumination system, a temperature control system, a pH and flue gas control system, a main power switch 12, an AC power supply 16, and a sampling system. The main power switch 12 is electrically connected with the AC power source 16, and controls the switching of the AC power source.

[0158] Photobioreactor 7 is a column photobioreactor, the side wall of the reactor is made of plexiglass tube, the bottom plate and top cover of the reactor are made of plexiglass plate, and the bottom plate of the reactor is bonded to the side w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com