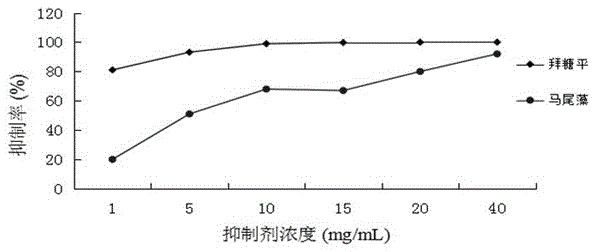

Preparation method of sargassum oligosaccharide and application of sargassum oligosaccharide in hypoglycemic drugs

A technology of sargassum and oligosaccharides, applied in the direction of drug combinations, medical preparations containing active ingredients, pharmaceutical formulas, etc., to achieve the effects of good inhibition of activity, promotion of glucose consumption, and reduction of enzyme dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

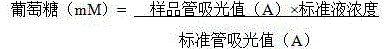

[0025] (1) Dried and pulverized Sargassum, added 95% ethanol to the dry powder of Sargassum and refluxed for 2 hours, the ratio of the weight of the dry powder to the volume of ethanol was 1:20, removed the ethanol after the reflux, and dried to obtain the dried and degreased Sargassum powder Distilled water is added to the Sargassum powder, wherein the mass of Sargassum and the volume ratio of distilled water are 1:30, and the water extraction method is used to extract for 2 hours at 90 ° C. After the extraction is completed, filter, and the filter residue is extracted twice by repeating the above steps. The obtained filtrate was mixed, concentrated, added 3 times the volume of 95% ethanol, left to settle at 4°C for 12 hours, centrifuged to collect the precipitate, vacuum freeze-dried and pulverized the crude polysaccharide of Sargassum;

[0026] (2) Adding distilled water to the crude polysaccharide of Sargassum obtained in step (1), wherein the mass ratio of the crude polysa...

Embodiment 2

[0068] (1) Dried and pulverized Sargassum, added 95% ethanol to the dry powder of Sargassum and refluxed for extraction for 1 hour. The ratio of dry powder weight to ethanol volume was 1:15. After the reflux was completed, the ethanol was removed and dried to obtain dry degreased Sargassum powder Distilled water is added to the Sargassum powder, wherein the mass of Sargassum and the volume ratio of distilled water are 1:25, and the water extraction method is used to extract for 2 hours at 85 ° C. After the extraction is completed, filter, and the filter residue is extracted twice by repeating the above steps. The obtained filtrate was mixed, concentrated, added 3 times the volume of 95% ethanol, left to settle at 4°C for 8 hours, centrifuged to collect the precipitate, vacuum freeze-dried and pulverized the Sargassum crude polysaccharide;

[0069] (2) Add distilled water to the Sargassum crude polysaccharide obtained in step (1), wherein the mass ratio of the Sargassum crude po...

Embodiment 3

[0079] (1) Dried and crushed Sargassum, added 95% ethanol to the dry powder of Sargassum and refluxed for 2 hours, the ratio of the weight of the dry powder to the volume of ethanol was 1:17, removed the ethanol after the reflux, and dried to obtain dry and defatted Sargassum powder Distilled water is added to the Sargassum powder, wherein the mass of Sargassum and the volume ratio of distilled water are 1:27, and the water extraction method is used to extract at 90° C. for 2 hours. After the extraction is completed, filter, and the filter residue is extracted 3 times by repeating the above steps. The obtained filtrate was mixed and then concentrated, and 4 times the volume of 95% ethanol was added. After standing at 7°C for 10 hours, the precipitate was collected by centrifugation, and the crude polysaccharide of Sargassum sargassum was pulverized after vacuum freeze-drying;

[0080] (2) Adding distilled water to the Sargassum crude polysaccharide obtained in step (1), wherein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com