Method for preparing monocrystal double-layer graphene

A double-layer graphene, single crystal technology, applied in the field of graphene, can solve the problems of unstable electronic properties of graphene, defects at the grain boundary of polycrystalline thin film graphene transport properties, etc., and achieves less defects, large size, and operation. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

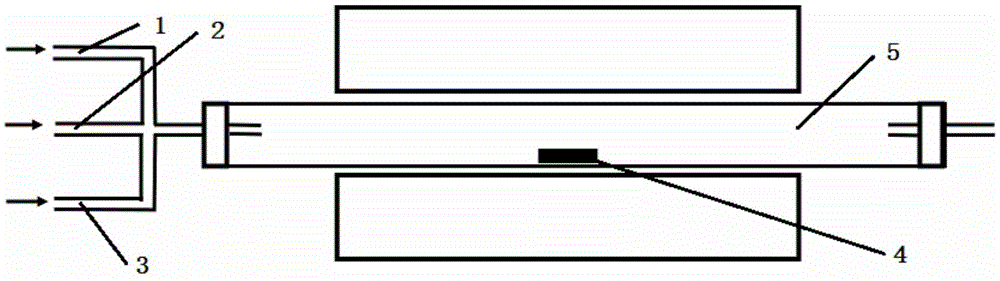

[0034] like figure 1 As shown, the carbon source is methane, of course it can also be acetylene, the copper catalyst is single crystal copper foil, the reactor is a quartz tube, the No. 1 tube is an argon tube, the No. 2 tube is a hydrogen tube, and the No. 3 tube is a methane gas tube.

[0035] A method for preparing single-crystal double-layer graphene, comprising the following steps:

[0036] a) Place the single crystal copper foil in the middle of a clean quartz tube, evacuate the quartz tube, then pass in argon gas, evacuate, pass in hydrogen gas, evacuate again, and repeat three times to remove the Air, then pass 500-1000sccm argon-hydrogen mixed gas into the quartz tube;

[0037] b) heating the single crystal copper foil so that the temperature in the central area of the quartz tube reaches 1000°C, and then keeping the temperature constant for 60 minutes, annealing the surface of the single crystal copper foil;

[0038] c) Continue to keep the temperature at 1000°C ...

Embodiment 2

[0042] like figure 1 As shown, the carbon source is methane, of course it can also be acetylene, the copper catalyst is single crystal copper foil, the reactor is a quartz tube, the No. 1 tube is an argon tube, the No. 2 tube is a hydrogen tube, and the No. 3 tube is a methane gas tube.

[0043] A method for preparing single-crystal double-layer graphene, comprising the following steps:

[0044] a) Place the single crystal copper foil in the middle of a clean quartz tube, evacuate the quartz tube, then pass in argon gas, evacuate, pass in hydrogen gas, evacuate again, and repeat three times to remove the Air, then pass 500-1000sccm argon-hydrogen mixed gas into the quartz tube;

[0045] b) heating the single crystal copper foil so that the temperature in the central area of the quartz tube reaches 1000°C, and then keeping the temperature constant for 90 minutes, annealing the surface of the single crystal copper foil;

[0046] c) Slowly cool down the central area of the ...

Embodiment 3

[0050] like figure 1 As shown, the carbon source is methane, the copper catalyst is polycrystalline copper foil, the reactor is a quartz tube, the No. 1 tube is an argon tube, the No. 2 tube is a hydrogen tube, and the No. 3 tube is a methane gas tube.

[0051] A method for preparing single-crystal double-layer graphene, comprising the following steps:

[0052] a) The polycrystalline copper foil is ultrasonically cleaned with deionized water, ethanol, acetone, and isopropanol in sequence, then blown dry with nitrogen, and then placed in the middle of the quartz tube of the chemical vapor deposition system, vacuumizes the quartz tube, and blows it to the quartz tube. Introduce argon and hydrogen into the tube to fill the reactor with argon-hydrogen mixed gas, repeat vacuuming three times to completely remove the air in the tube, and then inject argon-hydrogen mixed gas into the quartz tube again;

[0053] b) Heating the polycrystalline copper foil so that the temperature in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com