Method and device for removing nitrogen oxide in waste gas of marine diesel engine by use of sodium chlorite seawater solution

A technology using sodium chlorite and marine diesel engines, applied in the direction of using liquid separating agents, chemical instruments and methods, separation methods, etc., can solve the problem that the pH value of the solution is difficult to meet the discharge requirements, increase the initial investment cost of the equipment, and increase the area of the equipment. Area and other issues, to achieve the effect of reducing equipment costs and drug costs, facilitating flexible layout and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A method of using sodium chlorite seawater solution to remove nitrogen oxides in marine diesel engine exhaust gas has the following steps:

[0040] S1. Desulfurization and dust removal treatment: pump seawater into the desulfurization spray tower, and perform desulfurization and dust removal treatment on the exhaust gas from the diesel engine;

[0041] S2. Denitrification treatment: mix sodium chlorite aqueous solution with a solute mass fraction of 10%-40% with seawater to obtain sodium chlorite seawater solution, and then treat the obtained sodium chlorite seawater solution with desulfurization and dust removal to obtain The mixed reaction of exhaust gas, the NO in the obtained exhaust gas x Discharge when the content is lower than 2.0g / (kW h);

[0042] S3. Waste liquid treatment: The waste liquid obtained after desulfurization and dust removal treatment is subjected to solid-liquid separation treatment, and the obtained waste liquid is mixed with the waste liquid ob...

Embodiment 2

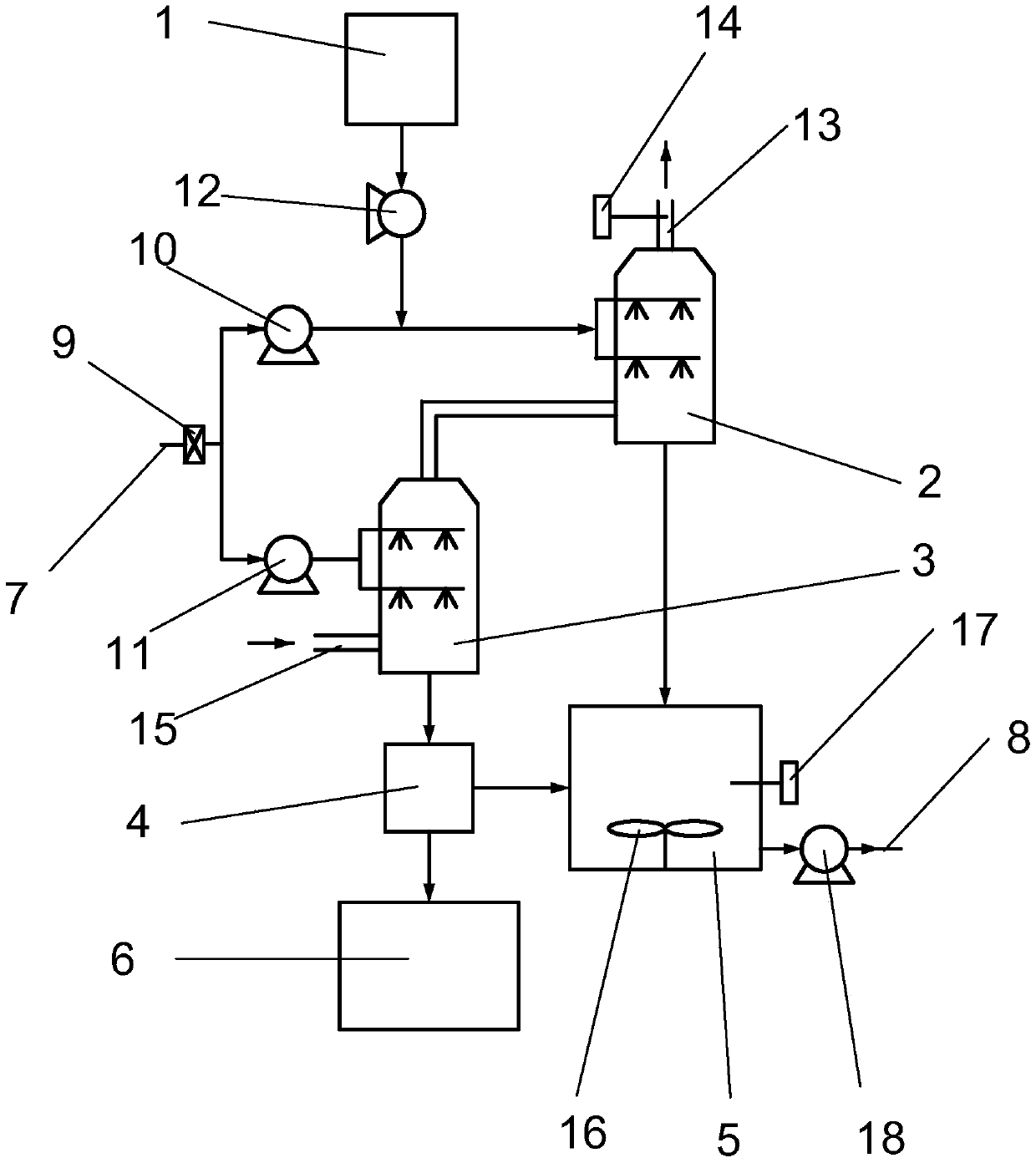

[0047] Such as figure 1 As shown, a device using sodium chlorite seawater solution to remove nitrogen oxides in marine diesel engine exhaust gas, including sodium chlorite solution water tank 1, denitrification spray tower 2, desulfurization spray tower 3, hydrocyclone 4. The mixing water tank 5, the sludge tank 6, the seawater inlet pipe 7 and the seawater drain pipe 8, the seawater inlet pipe 7 communicates with the spraying device of the denitrification spray tower 2 through the filter 9 and the seawater pump I10 in turn, The seawater inlet pipe 7 communicates with the spraying device of the desulfurization spray tower 3 through the filter 9 and the seawater pump II11 in turn, and a liquid dosing metering is provided between the seawater pump I10 and the denitrification spray tower 2 Pump 12, the liquid-adding metering pump 12 communicates with the sodium chlorite solution water tank 1, the top of the denitrification spray tower 2 is provided with a waste gas outlet 13, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com