A kind of preparation method of red copper and nickel base superalloy laminated composite component

A technology for nickel-based superalloys and composite components, applied in metal processing equipment, manufacturing tools, welding equipment, etc., can solve the problems of low material utilization rate and dust pollution, and achieve high-quality connection, high production efficiency, and joint interface stress. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the purpose, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

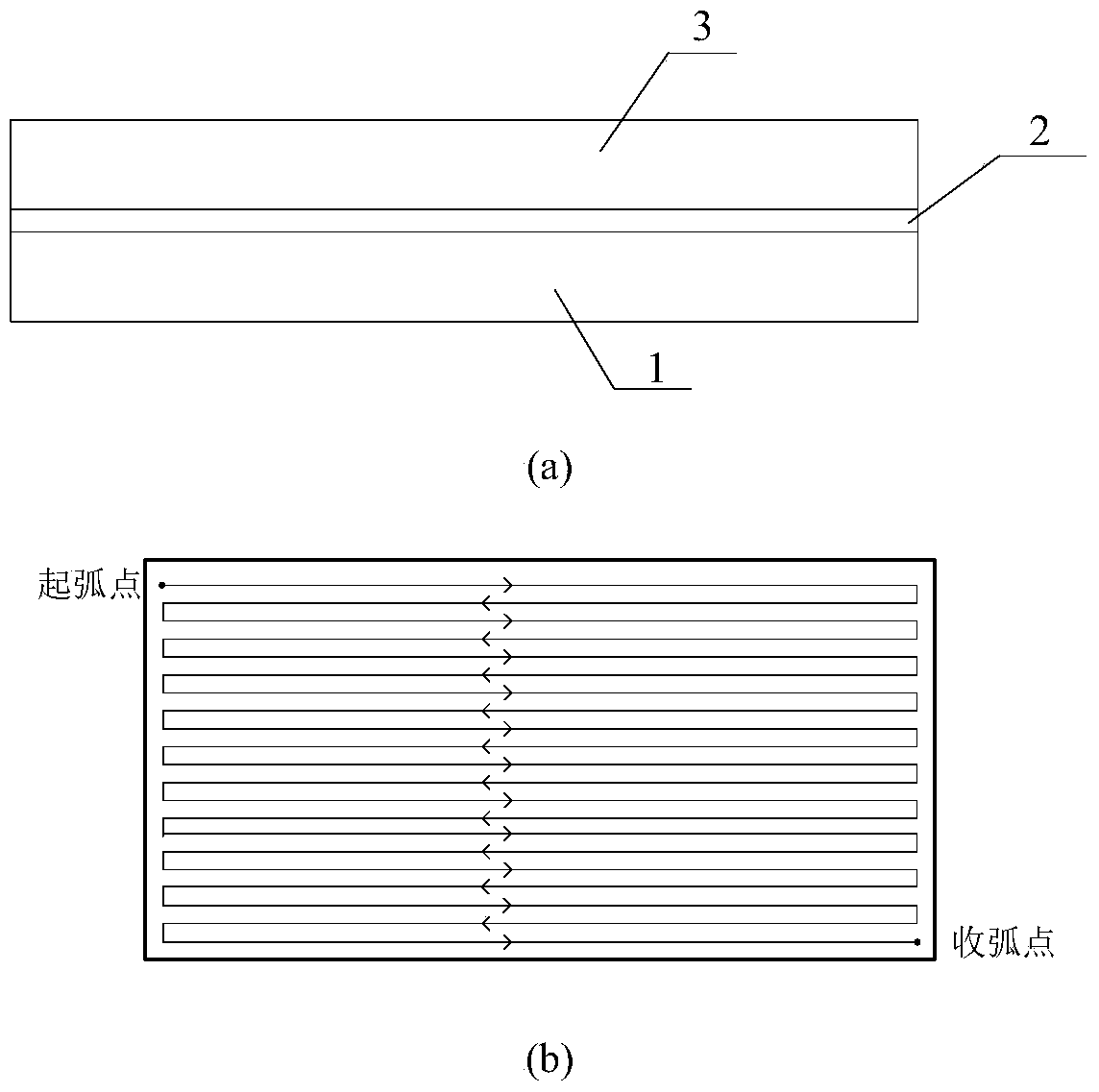

[0024] Such as figure 1 The size of the red copper and nickel-based superalloy composite component shown is 100mm×100mm×20mm, of which the copper component 1 (copper plate) is 12mm thick and the grade is T1; the nickel-based superalloy component 3 is GH3030, the thickness is 6mm, and the transition layer 2 is about 2mm thick.

[0025] Welding process platform: The processing device is composed of Fronius TPS400TIG power supply, IPG company YLS-6000 fiber laser heat source, Fronius wire feeder and KUKA robot; during processing, the heat source head and wire feeder tip are fixed on the KUKA robo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com