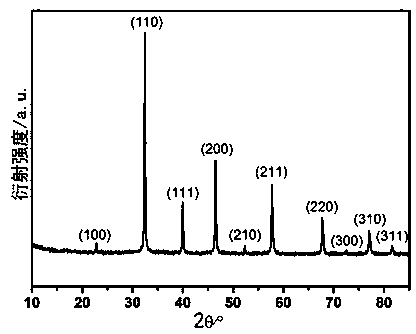

Hydrangea-like strontium titanate nano powder preparation method

A technology of nano-powder and hydrangea, which is applied in the direction of titanate, nanotechnology, alkaline earth metal titanate, etc., can solve the problems of troublesome product cleaning and great influence on use, and achieve high purity and crystallinity, dispersibility and Good particle size uniformity, convenient cleaning and post-application effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1) Dissolve 5mmol tetrabutyl titanate in 3mL ethylene glycol methyl ether, add ammonia water dropwise under stirring to form a gel, wash the resulting gel with deionized water until neutral, and obtain a titanium precursor Gel; dissolve 5mmol strontium nitrate in 10mL deionized water, stir and mix with the titanium precursor gel to obtain a suspension;

[0019] 2) Add 10 mL of an aqueous solution in which 0.107 mol of potassium hydroxide is dissolved in the suspension obtained in step 1), and stir to obtain a uniform suspension;

[0020] 3) Add the suspension in step 2) into the inner tank of the reactor, adjust the liquid volume in the inner tank of the reactor with deionized water to 7 / 8 of the volume of the inner tank, place the inner tank of the reactor in the reactor, and After being kept at 140° C. for 10 h, it was naturally cooled to room temperature, and the obtained product was washed with deionized water until neutral, then washed with absolute ethanol, and dr...

Embodiment 2

[0022] 1) Dissolve 5mmol tetrabutyl titanate in 2mL ethylene glycol methyl ether, add ammonia water dropwise under stirring to form a gel, wash the resulting gel with deionized water until neutral, and obtain a titanium precursor Gel; dissolve 5mmol strontium nitrate in 10mL deionized water, stir and mix with the titanium precursor gel to obtain a suspension;

[0023] 2) Add 10 mL of an aqueous solution in which 0.071 mol of potassium hydroxide is dissolved in the suspension obtained in step 1), and stir to obtain a uniform suspension;

[0024] 3) Add the suspension in step 2) into the inner tank of the reactor, adjust the liquid volume in the inner tank of the reactor with deionized water to 4 / 5 of the volume of the inner tank, place the inner tank of the reactor in the reactor, and After being kept at 140° C. for 10 h, it was naturally cooled to room temperature, and the obtained product was washed with deionized water until neutral, then washed with absolute ethanol, and dr...

Embodiment 3

[0026] 1) Dissolve 5 mmol tetrabutyl titanate in 2.5 mL ethylene glycol methyl ether, add ammonia water dropwise under stirring to form a gel, wash the resulting gel with deionized water until neutral, and obtain a titanium precursor body gel; dissolve 5mmol strontium nitrate in 10mL deionized water, stir and mix with the titanium precursor gel to obtain a suspension;

[0027] 2) Add 10 mL of an aqueous solution dissolved with 0.143 mol of potassium hydroxide to the suspension obtained in step 1), and stir to obtain a uniform suspension;

[0028] 3) Add the suspension in step 2) into the inner tank of the reactor, adjust the liquid volume in the inner tank of the reactor with deionized water to 4 / 5 of the volume of the inner tank, place the inner tank of the reactor in the reactor, and After being kept at 140° C. for 10 h, it was naturally cooled to room temperature, and the obtained product was washed with deionized water until neutral, then washed with absolute ethanol, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com