Preparation method of crosslinking poly(p-phenylenebenzobisoxazole) film

A technology of polyphenylene benzene and dioxazole, which is applied in the field of preparation of cross-linked polyphenylene benzobisoxazole films, can solve the problems of difficulty in controlling film thickness and shape, large shrinkage and the like, and achieves no The effect of complex residue, small shrinkage and controllable shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1: Synthesis of aromatic polyamide precursors with side methyl groups and phenolic hydroxyl groups

[0031] Into a 250ml three-neck flask, under nitrogen protection, first add 2.28g of 2-methyl-4,6-diaminoresorcinol dihydrochloride (0.01mol), 100ml of dry N-methylpyrrolidone and 2.5ml of dry pyridine After stirring for 10 minutes at 15°C, add 2.03g of terephthaloyl chloride, stir for 1 minute, then add 1.6ml of dry pyridine, stir for 2 hours at 15°C, pour into 200ml of water, filter, and dry to obtain 2.87g of yellow-green Solid (100% yield). n is 58.

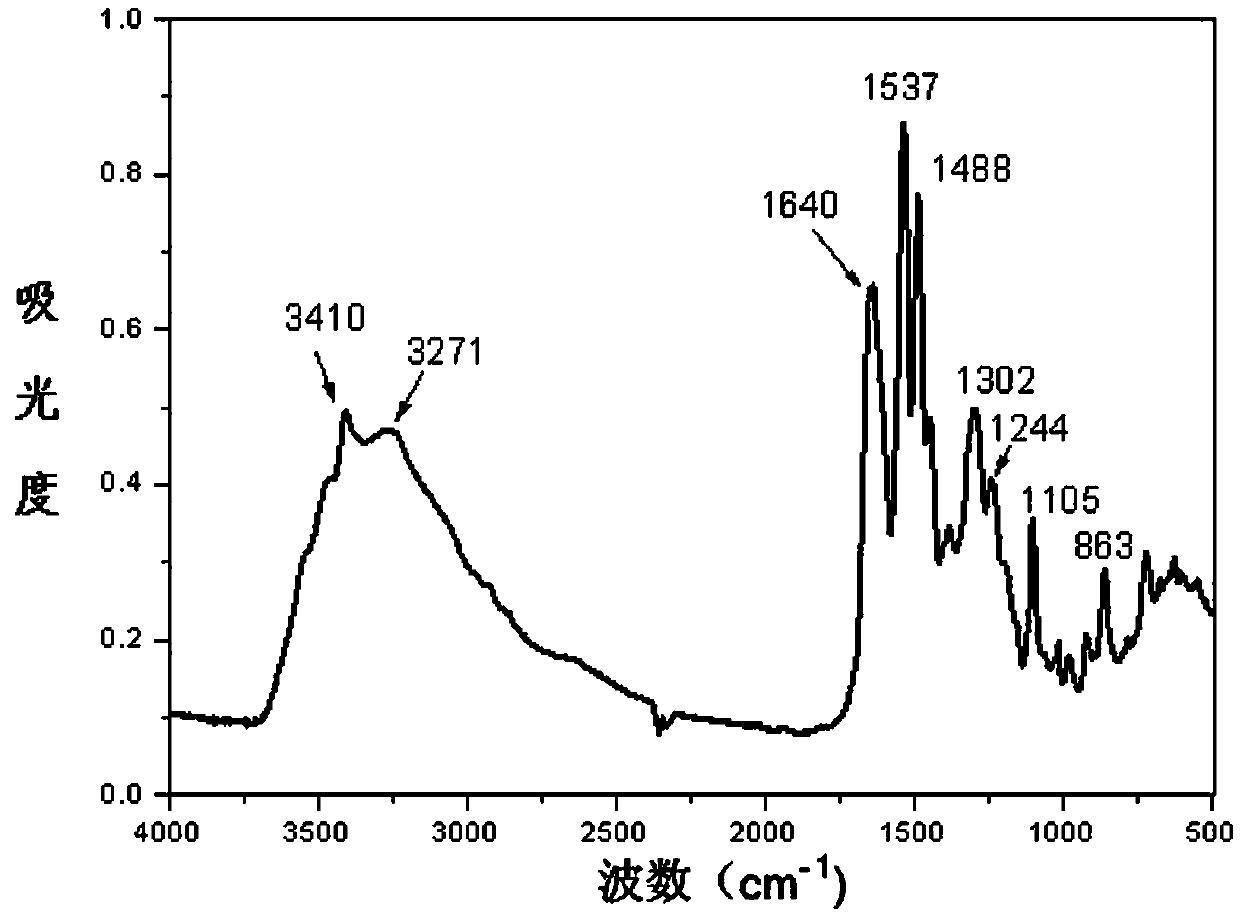

[0032] The polyamide precursor synthesized above was tested by IR and 1 HNMR detection, for the target product, IR and 1 HNMR analysis result is as follows:

[0033] IR (KBr, cm -1 ): 3410, 3271, 1640, 1537, 1244, 863; 1 HNMR (CDCl 3 , 400MHz, δ(ppm)): 10.06(s, 2H), 8.97(s, 2H), 8.10(m, 4H), 7.38(s, 1H), 2.16(s, 3H).

Embodiment 2

[0034] Embodiment 2: the preparation of cross-linked polyamide film

[0035] The polyamide synthesized above was stirred and dissolved in dimethyl sulfoxide at 100°C to prepare a solution with a concentration of 5%, and was coated on a glass plate or an aluminum plate by a solution casting method, or coated on a glass plate by a spin coating method The quartz plate was then continuously treated at 60° C., 70° C., 80° C., 100° C. and 120° C. for 1 hour each to obtain a polyamide film.

[0036] The polyamide film was placed on a hot stage at 350° C. for 1 hour in a nitrogen atmosphere to obtain a cross-linked PBO film, which was insoluble in non-cross-linked PBO solvents, such as methanesulfonic acid and concentrated sulfuric acid.

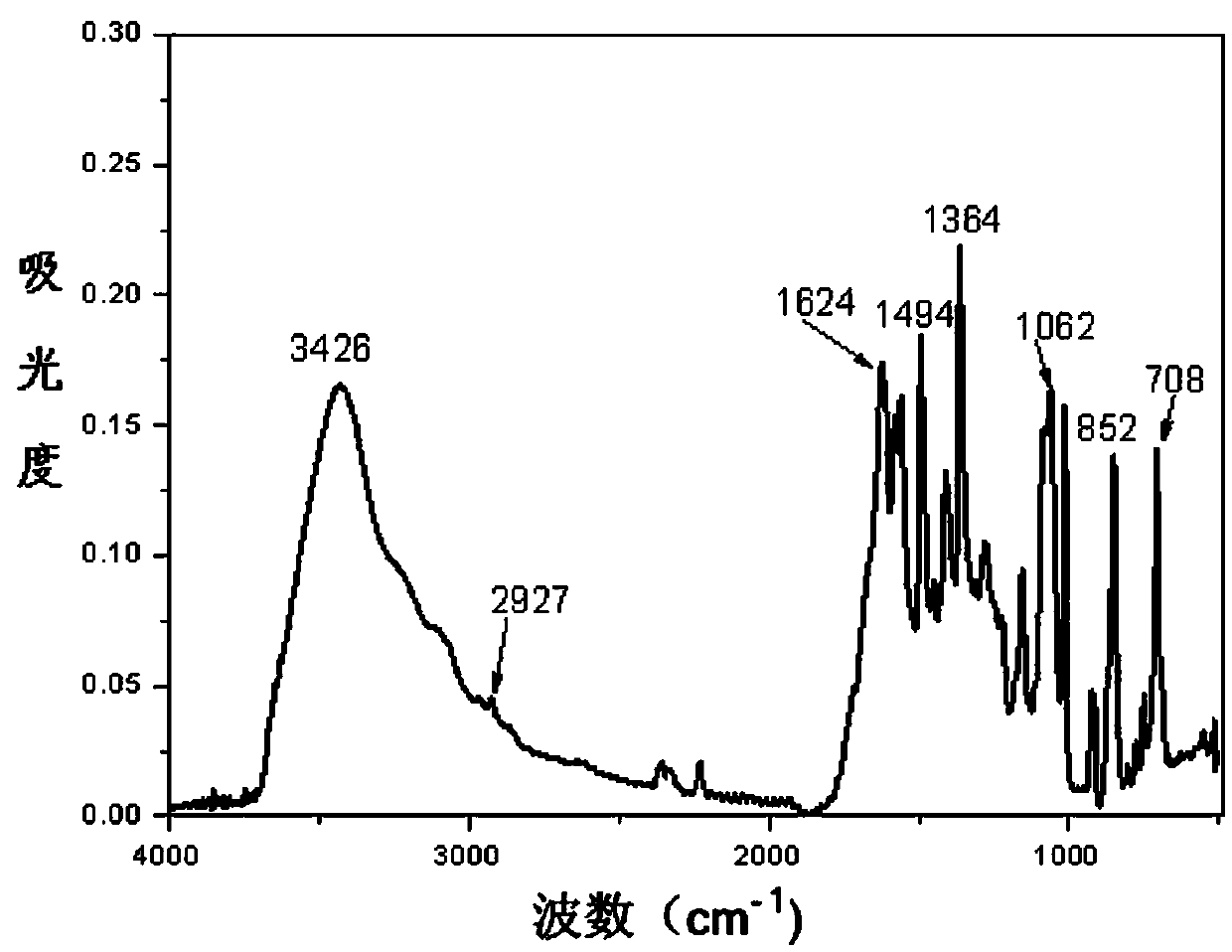

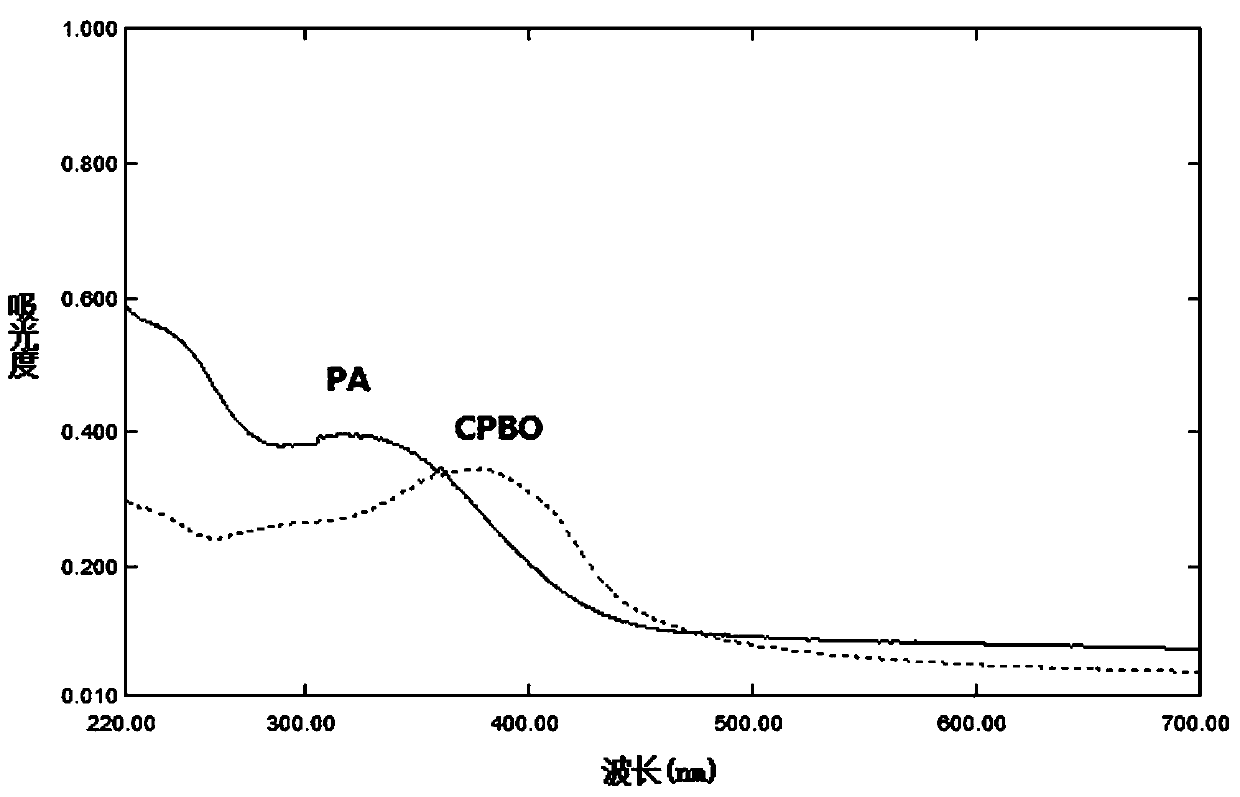

[0037] The cross-linked PBO film prepared above was detected by IR and ultraviolet-visible light. IR analysis results are as follows: IR (KBr, cm -1 ): 3427, 2927, 1624, 1364, 1062; in the ultraviolet-visible light absorption spectrum, the absorpt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com