A high-strength joining process of w‑cu alloy and the same material

A high-strength technology of the same material, applied in metal processing equipment, welding/cutting media/materials, welding media, etc., can solve the problems of cumbersome and complicated manufacturing processes, low connection strength, and large cost investment, and achieve convenience and wide application Popularization and application, fine joint structure and excellent plastic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

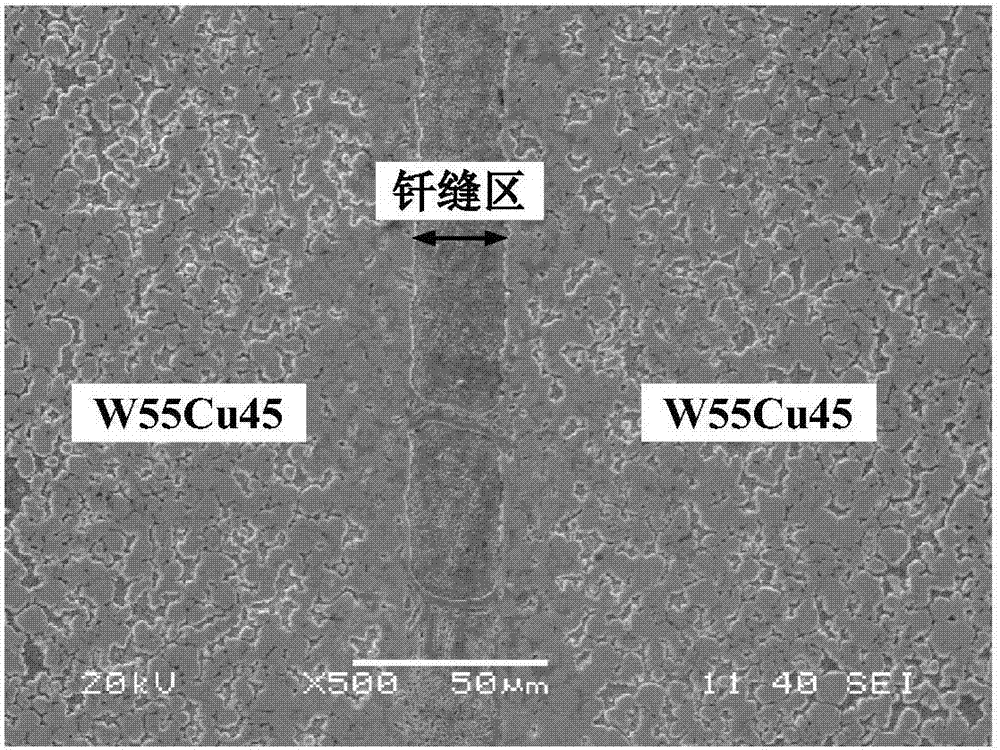

[0022] The W-Cu alloy (W55Cu45, wt%) is butt vacuum brazed. The size of the two W-Cu alloy samples is 20mm×20mm×5mm, and the surface to be brazed is 20mm×5mm.

[0023] The composition and mass percentage of the solder are: Cu78.8%, Mn7.8%, Co4.7%, Ni2.4%, Zr3.5%, Ti2.8%, and the thickness of the solder is 150 μm.

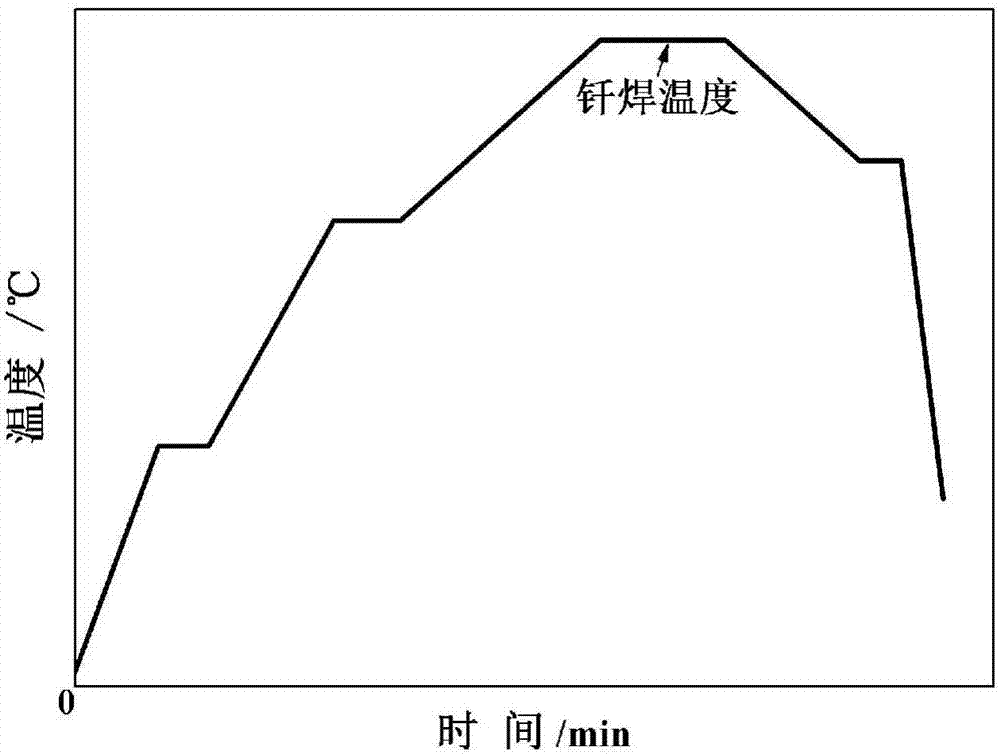

[0024] The brazing process steps are:

[0025] (1) Preparation: Clean up the W-Cu alloy and solder to be brazed, using 5% HF, 20% HNO 3 and 75%H 2 Pickling with O solution, cleaning the W-Cu alloy surface for 5 minutes, using W28, W14, W7, W3.5 metallographic sandpaper to polish the surface of the W-Cu alloy to be welded smooth and W5, W3.5 metallographic sandpaper for brazing Polish the surface of the material foil to remove impurities, oil stains and oxide films on the surface, place the W-Cu composite material and the solder foil in acetone, use ultrasonic cleaning for 15 minutes, and perform drying treatment;

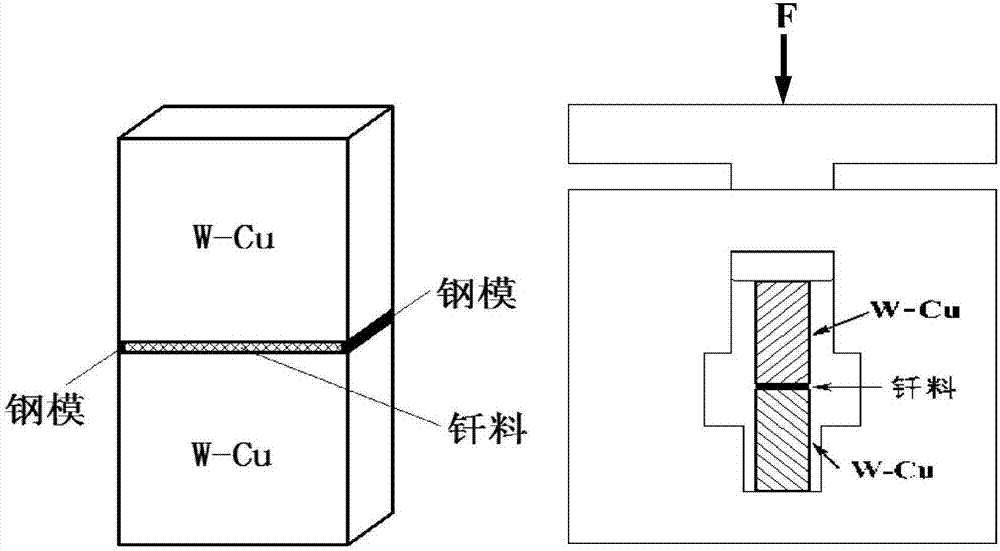

[0026] (2) Assembly: Place the cleaned brazing m...

Embodiment 2

[0030] The W-Cu alloy (W55Cu45, wt%) is butt vacuum brazed. The size of the two W-Cu alloy samples is 20mm×20mm×5mm, and the surface to be brazed is 20mm×5mm.

[0031] The composition and mass percentage of the solder are: Ag70.5%, Cu23%, Ti3.8%, Ni2.5%, B0.2%, and the thickness of the solder is 100 μm.

[0032] The brazing process steps are:

[0033] (1) Preparation: Clean up the W-Cu alloy and solder to be brazed, using 5% HF, 20% HNO 3 and 75%H 2 Pickling with O solution, cleaning the W-Cu alloy surface for 5 minutes, using W28, W14, W7, W3.5 metallographic sandpaper to polish the surface of the W-Cu alloy to be welded smooth and W5, W3.5 metallographic sandpaper for brazing Polish the surface of the material foil to remove impurities, oil stains and oxide films on the surface, place the W-Cu composite material and the solder foil in acetone, use ultrasonic cleaning for 10 minutes, and perform drying treatment;

[0034] (2) Assembly: Place the cleaned brazing material fo...

Embodiment 3

[0038] The W-Cu alloy (W75Cu25, wt%) is butt vacuum brazed. The size of the two W-Cu alloy samples is 20mm×20mm×6mm, and the surface to be brazed is 20mm×6mm.

[0039] The composition and mass percentage of the solder are: Cu78.8%, Mn7.8%, Co4.7%, Ni2.4%, Zr3.5%, Ti2.8%, and the thickness of the solder is 150 μm.

[0040] The brazing process steps are:

[0041] (1) Preparation: Clean up the W-Cu alloy and solder to be brazed, using 5% HF, 20% HNO 3 and 75%H 2 Pickling with O solution, cleaning the surface of W-Cu alloy for 10min, using W28, W14, W7, W3.5 metallographic sandpaper to polish the surface of W-Cu alloy to be welded smooth and W5, W3.5 metallographic sandpaper for soldering Polish the surface of the material foil to remove impurities, oil stains and oxide films on the surface, place the W-Cu composite material and the solder foil in acetone, use ultrasonic cleaning for 15 minutes, and perform drying treatment;

[0042] (2) Assembly: Place the cleaned brazing mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com