Graphene-wrapped ultra-dispersed nanomolybdenum carbide electrocatalytic hydrogen production catalyst and preparation method thereof

A graphene-wrapped, molybdenum carbide technology, applied in circuits, electrical components, battery electrodes, etc., can solve problems such as difficulty in achieving highly uniformly dispersed ultra-fine nanostructures, affecting the activity of electrocatalysts, and collapse of catalyst pore structures. Achieve the effect of improving the activity and stability of electrocatalytic hydrogen production, reducing overpotential, and abundant sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

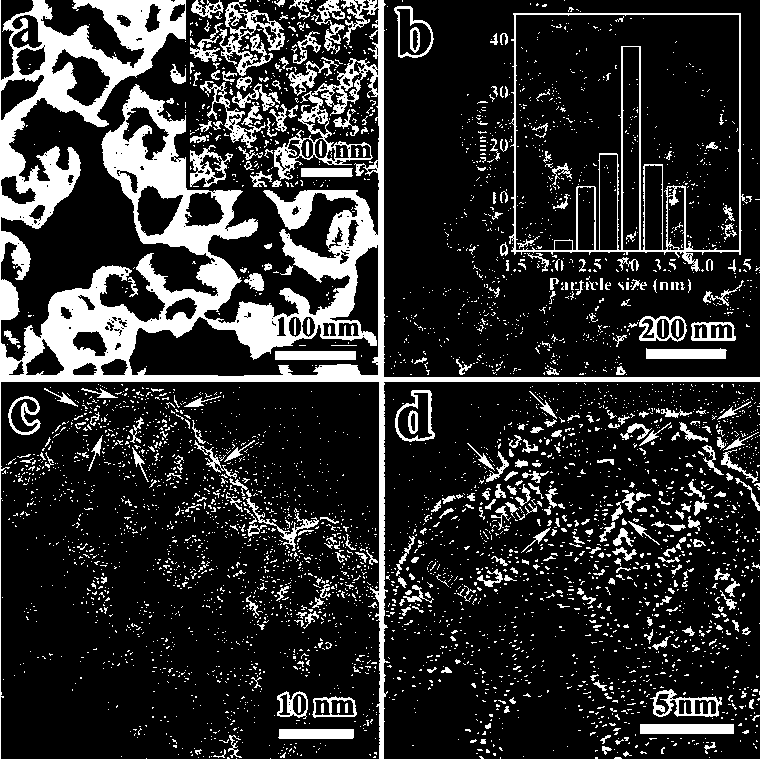

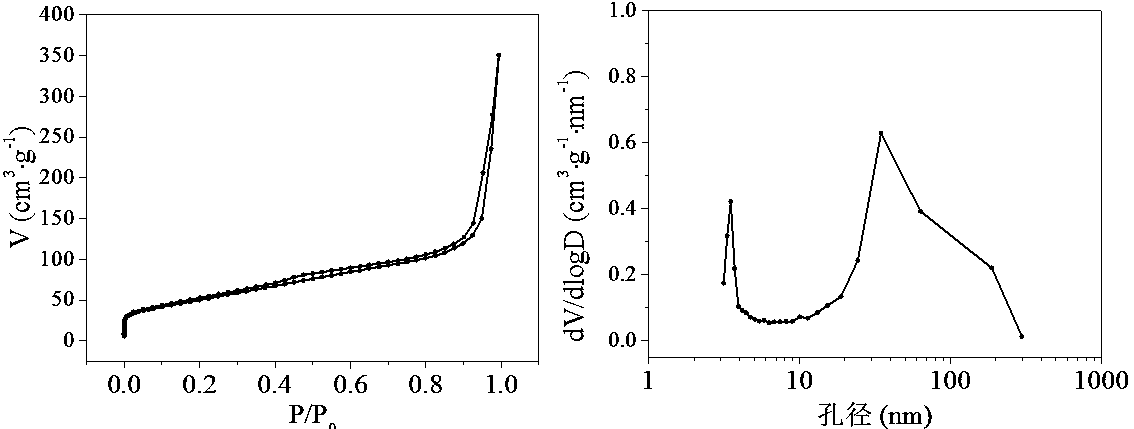

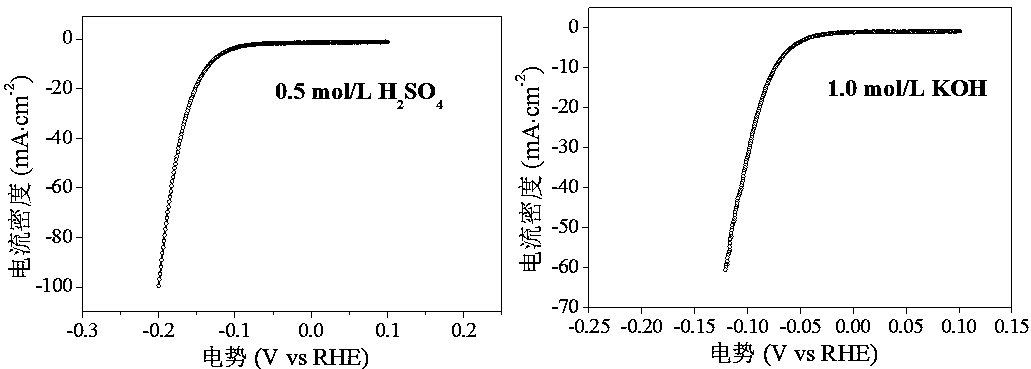

[0021] Example 1, Mo 3 (BTC) 2 (Mo-MOFs) As for the tube furnace, under the protection of argon, the temperature was programmed to 700 ℃ for carbonization for 5 hours, and the heating rate was controlled at 5 ℃ / min to prepare the graphene-wrapped ultra-dispersed nanomolybdenum carbide electrocatalyst Hydrogen production catalyst. Such as figure 1 Shown: The as-prepared electrocatalytic hydrogen production catalyst consists of ultra-dispersed nano-MoC (~3 nm) wrapped by 1~3 layers of graphene; as figure 2 Shown: the catalyst has a large specific surface area (187 m 2 / g) and abundant dual-pore structure (3~4 nm and 20~300 nm).

[0022] The electrochemical test of the ultra-dispersed nano-molybdenum carbide electrocatalytic hydrogen production catalyst wrapped by graphene is carried out in the following steps:

[0023] (a) Weigh 15 mg of the graphene-wrapped ultra-dispersed nanomolybdenum carbide electrocatalytic hydrogen production catalyst and disperse it in a solution c...

Embodiment 2

[0026] Embodiment 2, Mo 3 (BTC) 2 (Mo-MOFs) As for the tube furnace, under the protection of argon, the temperature was programmed to 800 ℃ for 5 hours, and the heating rate was controlled at 5 ℃ / min, and the graphene-wrapped ultra-dispersed nanomolybdenum carbide electrocatalyst Hydrogen production catalyst.

[0027] The electrochemical test of the prepared graphene-wrapped ultra-dispersed nanomolybdenum carbide electrocatalytic hydrogen production catalyst is the same as the steps (a) and (b) of the implementation case 1.

[0028] The electrocatalyst exhibited high hydrogen evolution activity in acidic conditions with a current density of -10 mA / cm 2 The overpotential under the conditions is 159 mV.

Embodiment 3

[0029] Embodiment 3, Mo 3 (BTC) 2 (Mo-MOFs) As for the tube furnace, under the protection of argon, the temperature was programmed to 900 °C for 5 hours, and the heating rate was controlled at 5 °C / min, and the graphene-wrapped ultra-dispersed nanomolybdenum carbide electrocatalyst Hydrogen production catalyst.

[0030] The electrochemical test of the prepared graphene-wrapped ultra-dispersed nanomolybdenum carbide electrocatalytic hydrogen production catalyst is the same as the steps (a) and (b) of the implementation case 1.

[0031] The electrocatalyst exhibited high hydrogen evolution activity in acidic conditions with a current density of -10 mA / cm 2 The overpotential under the conditions is 185 mV.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com