852nm ultra-narrow line width external-cavity semiconductor laser

An ultra-narrow linewidth, laser technology, applied in the field of 852nm ultra-narrow linewidth external cavity semiconductor lasers, can solve problems such as unfavorable laser frequency stabilization, grating vibration sensitivity, affecting frequency stability and linewidth of external cavity lasers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

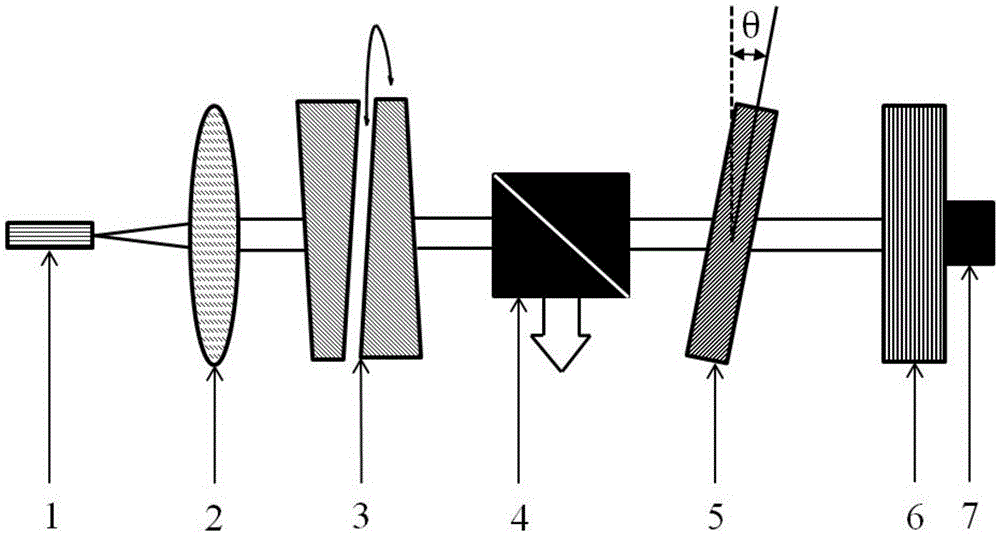

[0019] Such as figure 2 As shown, an 852nm ultra-narrow linewidth external cavity semiconductor laser mainly includes a semiconductor laser gain chip 1 and a collimator lens 2 sequentially placed on the light emitting direction of the semiconductor laser gain chip 1, a rotatable wedge prism pair 3, and a cubic split Beamer 4, rotatable all-dielectric film Fabry-Perot filter 5, total reflection mirror 6 and piezoelectric actuator 7;

[0020] Combine below figure 2 Introduce the method of realizing 852nm ultra-narrow linewidth external cavity semiconductor laser;

[0021] Step 1. Use Metal Organic Chemical Vapor Deposition (MOCVD) epitaxy to grow the epitaxial structure of the semiconductor gain chip, and combine photolithography, etching, oxidation, sputtering, coating and other processes to prepare the gain die. The gain die is at room temperature The lasing wavelength is 852nm, and the light-emitting surface is coated with Al with a reflectivity of less than 0.01%. 2 o ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Full width at half height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com