A preparation method of an adsorbent for removing heavy metals and ammonia nitrogen in wastewater

An adsorbent and heavy metal technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, ion-exchanged water/sewage treatment, etc., can solve the problems of occupying land and polluting the environment, reducing treatment costs and achieving high impurity removal rate , the effect of simple processing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

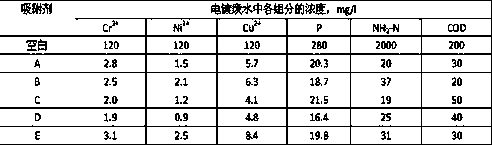

Examples

Embodiment 1

[0022] (1) Add 40 g of magnesium carbonate and 47 g of kaolin to 240 g of catalyst filter residue, stir for 2 hours, spray and granulate the uniform slurry, and the median diameter of the sprayed microspheres is 55 μm;

[0023] (2) Roast the spray material in (1) at 500 °C for 5 hours;

[0024] (3) Add 25 ml of water, 16 g of magnesium carbonate, 47 g of kaolin, and 4 g of potassium acetate to the roasted material in (2), stir well, extrude and shape the material, and dry the formed material at 100°C for 24 hours to obtain Adsorbent A.

Embodiment 2

[0026] (1) Add 30 g of calcium borate and 43 g of bentonite to 1920 g of catalyst filter residue, stir for 4 hours, spray and granulate the uniform slurry, and the median diameter of the sprayed microspheres is 50 μm;

[0027] (2) Roast the spray material in (1) at 1000°C for 0.5 hours;

[0028] (3) Add 100 ml of water, 18 g of calcium borate, 36 g of kaolin, and 12 g of ethylene glycol to the roasted material in (2), stir well, roll into a ball, and dry the formed material at 150°C for 10 h to produce into adsorbent B.

Embodiment 3

[0030] (1) Add 13 g of aluminum chloride and 18 g of attapulgite to 232 g of catalyst filter residue, stir for 2 hours, spray and granulate the uniform slurry, and the median diameter of the sprayed microspheres is 60 μm;

[0031] (2) Roast the spray material in (1) at 800 °C for 2.5 hours;

[0032] (3) Add 30 ml of water, 7 g of aluminum chloride, and 15 g of attapulgite to the roasted material in (2), stir well, press into tablets, and dry the formed material at 120°C for 19 hours to make an adsorbent c.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com