A kind of preparation method of highly selective palladium catalyst

A palladium catalyst and high-selectivity technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, inorganic chemistry, etc., to achieve the effects of simple process operation, improved adsorption capacity, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

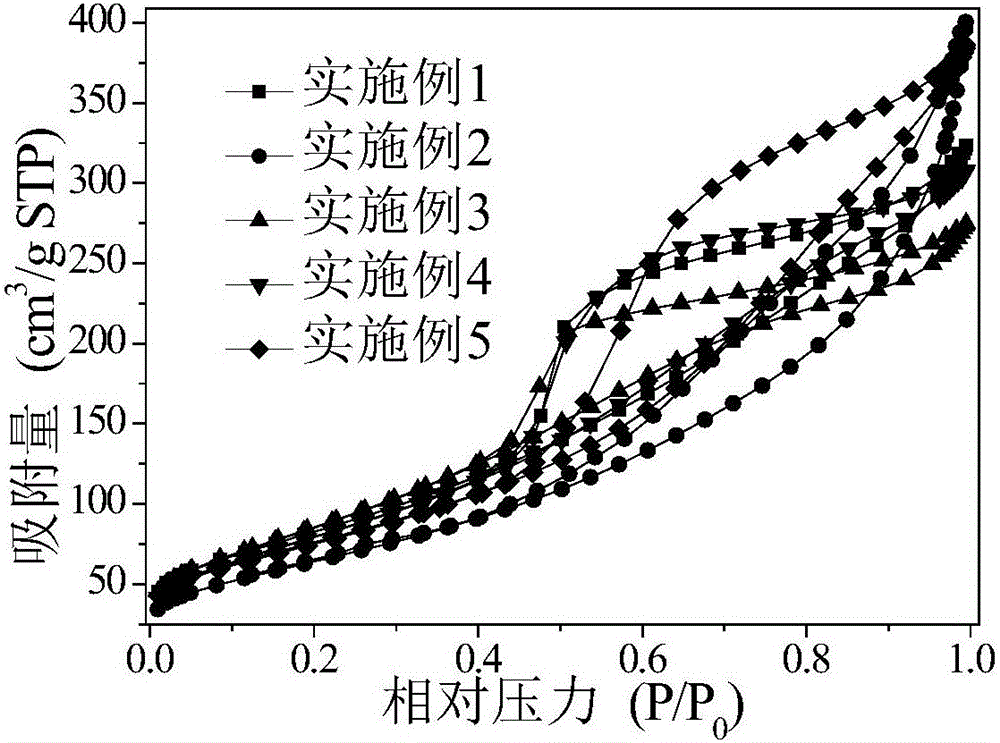

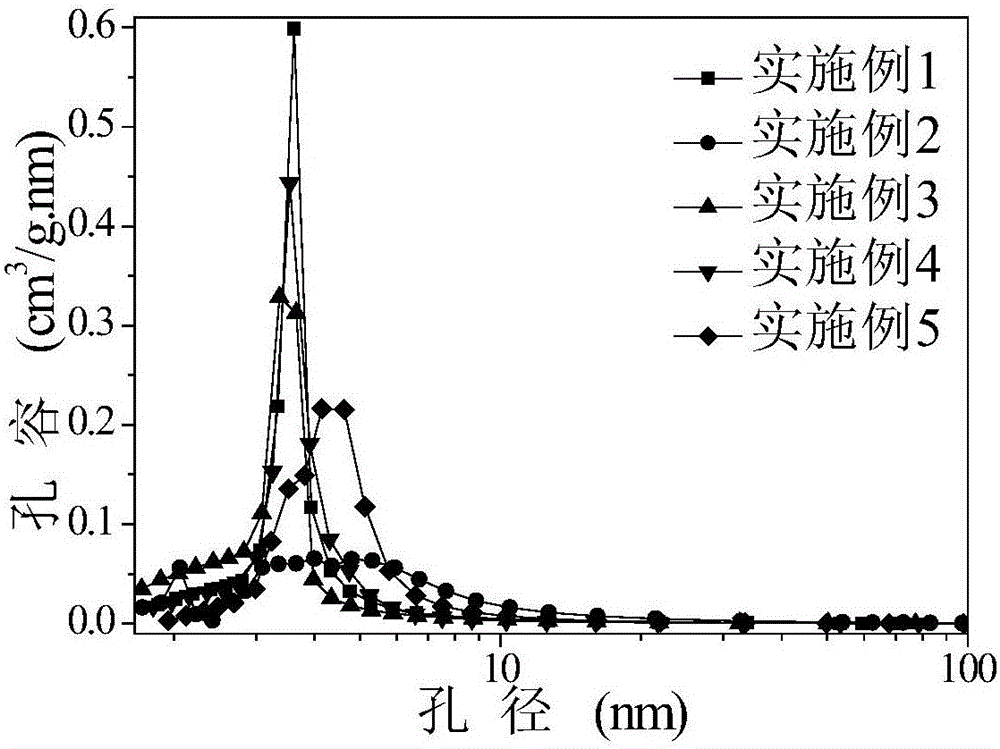

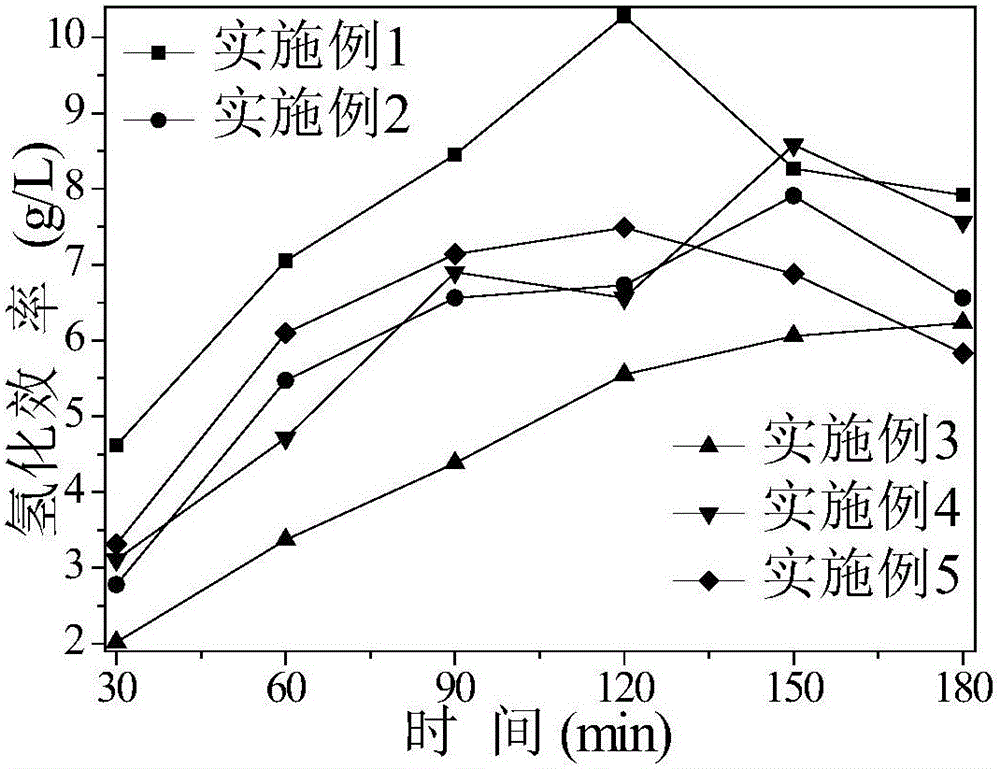

[0028] First, 0.048 g of 2-ethylanthraquinone (4 wt %) was dissolved in 45 mL of isopropanol with sufficient stirring at room temperature. Next, 4.8 g of aluminum isopropoxide was added, stirred at 72° C., and fully dissolved. Then, a mixed solution prepared by 1.27mL of water and 0.67mL of acetic acid (molar ratio water: acetic acid=6:1) was added dropwise thereto, and fully stirred at room temperature for 0.5h to obtain a sol, which was put into an oven and heated at 80 Aging at constant temperature for 20 hours at ℃, the gel obtained after aging was centrifuged and washed 3 times with isopropanol; finally, γ-Al 2 o 3 .

[0029] Take the above 1.2g γ-Al 2 o 3 , impregnated with an equal volume of aqueous solution prepared by 0.0060g palladium chloride and 0.0040g sodium chloride at 60°C for 2h, washed with distilled water, and suction filtered until there was no Cl in the filtrate - , and then dried in an oven at 120°C for 2h, further calcined at 450°C for 4h, and final...

Embodiment 2

[0032] First, 0.168 g of 2-ethylanthraquinone (14 wt %) was thoroughly stirred and dissolved in 45 mL of isopropanol at room temperature. Next, 4.8 g of aluminum isopropoxide was added, stirred at 72° C., and fully dissolved. Then, a mixed solution prepared by 0.85mL of water and 0.67mL of acetic acid (molar ratio water: acetic acid=4:1) was added dropwise thereto, and fully stirred at room temperature for 1.5h to obtain a sol, which was put into an oven and heated at 80 Aging at constant temperature for 20 hours at ℃, centrifuging and washing the gel obtained after aging for 3 times with isopropanol; finally, vacuum drying at 80℃ for 6 hours and roasting at 700℃ for 3 hours to obtain γ-Al 2 o 3 .

[0033] Take the above 1.2g γ-Al 2 o 3 , impregnated with an equal volume of aqueous solution prepared by 0.0040g palladium chloride and 0.0026g sodium chloride at 60°C for 2h, washed with distilled water, and suction filtered until there was no Cl in the filtrate - , and then ...

Embodiment 3

[0036] First, 0.108 g of 2-ethylanthraquinone (9 wt %) was thoroughly stirred and dissolved in 45 mL of isopropanol at room temperature. Next, 4.8 g of aluminum isopropoxide was added, stirred at 72° C., and fully dissolved. Then, a mixed solution prepared by 2.12 mL of water and 0.67 mL of acetic acid (molar ratio water: acetic acid = 10:1) was added dropwise thereto, and stirred thoroughly at room temperature for 3 hours to obtain a sol, which was put into an oven and heated at 80° C. After aging at constant temperature for 20 hours, the aged gel was centrifuged and washed 3 times with isopropanol; finally, it was vacuum-dried at 80°C for 9 hours and calcined at 400°C for 5 hours to obtain γ-Al 2 o 3 .

[0037] Take the above 1.2g γ-Al 2 o 3 , impregnated with an equal volume of aqueous solution prepared by 0.0020g palladium chloride and 0.0013g sodium chloride at 60°C for 2h, washed with distilled water, and suction filtered until there was no Cl in the filtrate - , an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com