A kind of isobutane dehydrogenation catalyst and preparation method thereof

A dehydrogenation catalyst and isobutane technology, applied in the direction of catalyst carrier, chemical instrument and method, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problem of deep dehydrogenation and cracking of isobutane, mechanical strength and Unsatisfactory high temperature stability, platinum dispersion, particle size distribution and surface morphology are not easy to control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

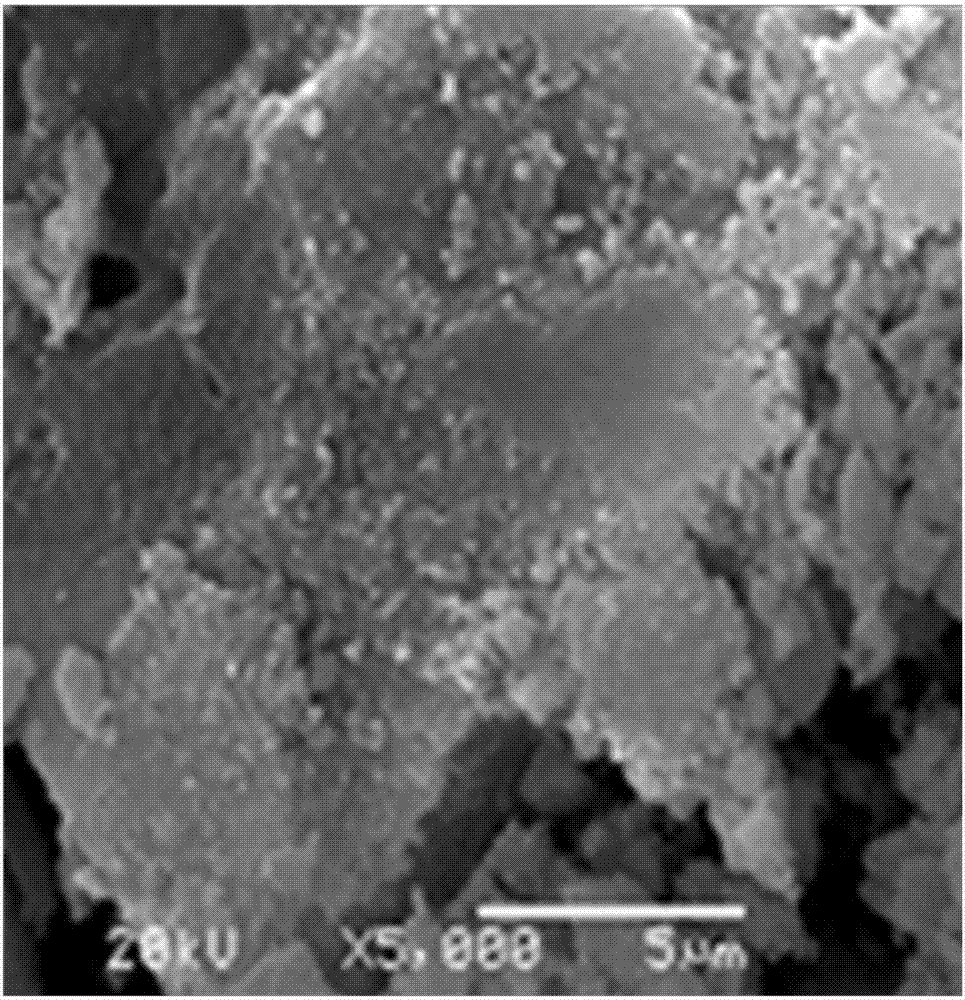

Image

Examples

Embodiment 1

[0088] Embodiment 1: Preparation of isobutane dehydrogenation catalyst

[0089] The implementation steps of this embodiment are as follows:

[0090] A. Catalyst carrier preparation

[0091] According to NH 4 VO 3 , Al(NO 3 ) 3 9H 2 O and Fe(NO 3 ) 3 9H 2 The mass ratio of O is 19:60:2, and NH 4 VO 3 Dissolved in saturated oxalic acid solution to obtain ammonium metavanadate solution; Al(NO 3 ) 3 9H 2 O and Fe(NO 3 ) 3 9H 2 O was dissolved in deionized water, and then added 4% ethylene glycol dispersant based on the total equivalent of metal ions to obtain a solution with a total equivalent concentration of iron and aluminum metal ions of 0.1 mol / L;

[0092] The above two solutions were slowly added to the deionized water in parallel, and then the precipitant was slowly added dropwise until it was in the form of a sol, and then transferred to an autoclave for 12 hours at a temperature of 200 ° C, and then heated to a pressure of 3.0MPa, and maintained at this p...

Embodiment 2

[0101] Embodiment 2: Preparation of isobutane dehydrogenation catalyst

[0102] The implementation steps of this embodiment are as follows:

[0103] A. Catalyst carrier preparation

[0104] According to NH 4 VO 3 , Al(NO 3 ) 3 9H 2 O and Fe(NO 3 ) 3 9H 2 The mass ratio of O is 23:50:5, and NH 4 VO 3 Dissolved in saturated oxalic acid solution to obtain ammonium metavanadate solution; Al(NO 3 ) 3 9H 2 O and Fe(NO 3 ) 3 9H 2 O is dissolved in deionized water, and then added with 1% ethanol dispersant based on the total equivalent of metal ions to obtain a solution with a total equivalent concentration of iron and aluminum metal ions of 0.5 mol / L;

[0105] The above two solutions were slowly added to the deionized water in parallel, and then the precipitant was slowly added dropwise until it was in the form of a sol, and then transferred to an autoclave for 24 hours at a temperature of 160°C, and then heated to a pressure of 2.0MPa, and maintained at this pressur...

Embodiment 3

[0114] Embodiment 3: Preparation of isobutane dehydrogenation catalyst

[0115] The implementation steps of this embodiment are as follows:

[0116] A. Catalyst carrier preparation

[0117] According to NH 4 VO 3 , Al(NO 3 ) 3 9H 2 O and Fe(NO 3 ) 3 9H 2 The mass ratio of O is 20:55:3, and NH 4 VO 3 Dissolved in saturated oxalic acid solution to obtain ammonium metavanadate solution; Al(NO 3 ) 3 9H 2 O and Fe(NO 3 ) 3 9H 2 O was dissolved in deionized water, and then added 2.5% isopropanol dispersant based on the total equivalent of metal ions to obtain a solution with a total equivalent concentration of iron and aluminum metal ions of 0.3 mol / L;

[0118] The above two solutions were slowly added to the deionized water in parallel, and then the precipitant was slowly added dropwise until it was in the form of a sol, and then transferred to an autoclave for 18 hours at a temperature of 180°C, and then heated up to a pressure of 2.5MPa, and maintained at this pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com