A method and device for realizing short-cut nitrification and denitrification in constructed wetland

A short-range nitrification and artificial wetland technology, applied in the field of environmental engineering, can solve the problems of few reports on the application of artificial wetlands and difficult adjustment of operating conditions, and achieve the effect of promoting denitrification reaction and improving denitrification efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

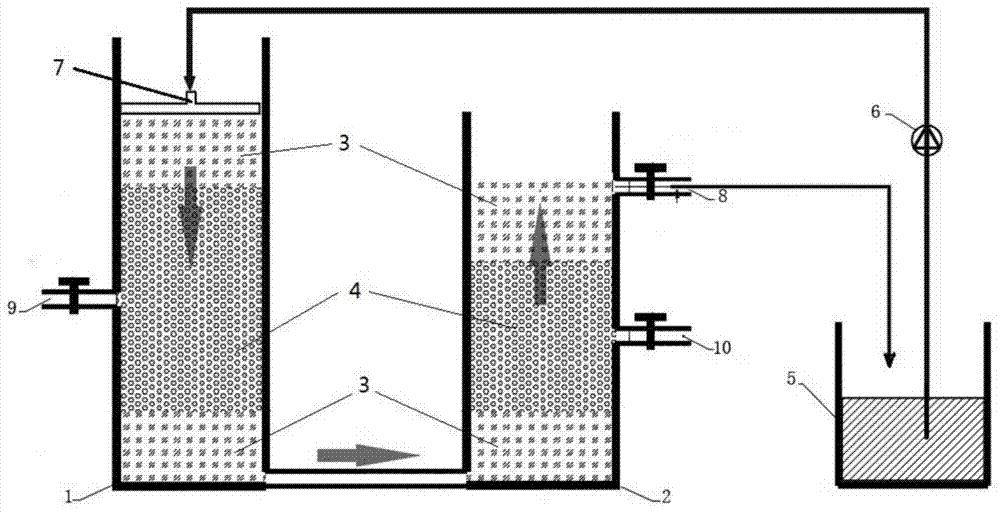

[0035] Such as figure 1As shown, a device for realizing a short-range nitrification and denitrification method in a constructed wetland includes a constructed wetland system I pool 1 and II pool 2, and the constructed wetland system also includes a water storage tank 5 and an aeration pump 6, and the I pool 1 The bottom of the bottom is connected with the bottom of II pool 2, and the top of said II pool 2 is connected with water storage tank 5, and the outlet pipe of said water storage tank 5 is connected with the top of I pool 1 through aeration pump 6; Limestone 3 and sand 4 with The limestone-sand-limestone gradation filling system, the inlet pipe 7 is located above the I pool, and the outlet pipe 8 is located above the II pool. Fill the lower layer and the upper layer of the I pond 1 into the limestone 3 with 10% volume of the I pond 1 and an average particle diameter of 1 mm; after mixing the activated sludge and the sand 4 less than 10 mesh according to the mass ratio of...

Embodiment 2

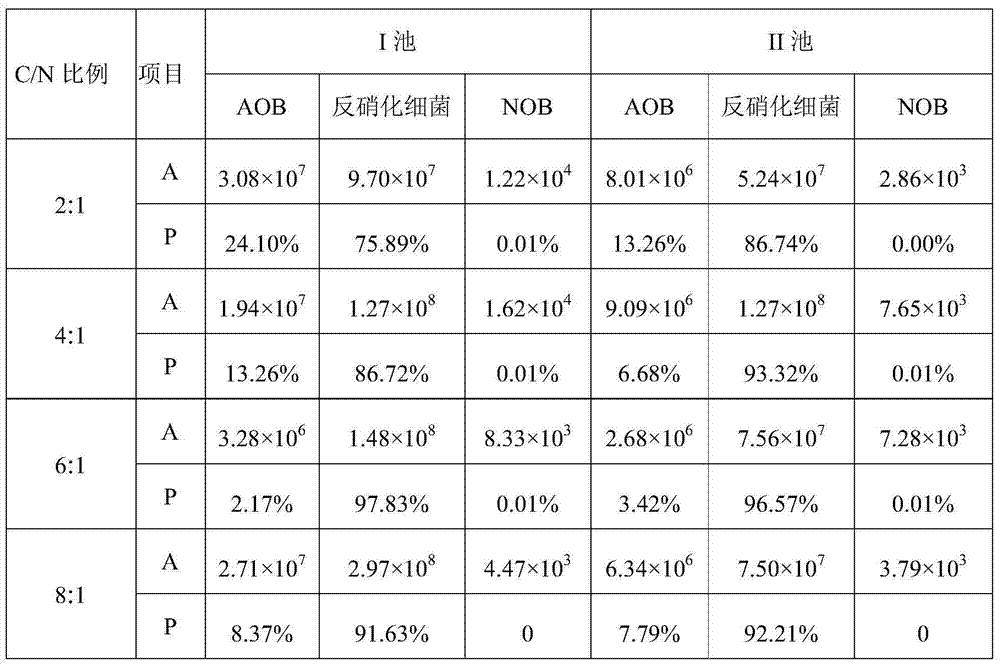

[0049] Adopt the method of embodiment 1 to carry out short-range nitrification and denitrification in artificial wetland, when implementing, adjust influent water quality to be: NH 4 + -N concentration is 20mg / L, H 2 PO 4 - -P concentration is 8mg / L, by adding 1.8g~3.6g glucose as carbon source to achieve organic carbon (OC) concentration of 80~160mg / L, so as to adjust the carbon-nitrogen ratio between 4~8.

[0050] After 30 days of continuous operation, the removal efficiency of TN in the constructed wetland system reached over 94%. 4 + The removal rate of -N reaches 90% to 99.6%, and the removal rate of organic carbon reaches 96% to 99%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com