Preparation method for mullite in-situ reinforced silicon carbide porous ceramic sintered at low temperature

A technology of low-temperature sintering and porous ceramics, which is applied in ceramic products, applications, household appliances, etc., to achieve the effects of improving high-temperature mechanical properties, improving oxidation resistance, and good mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

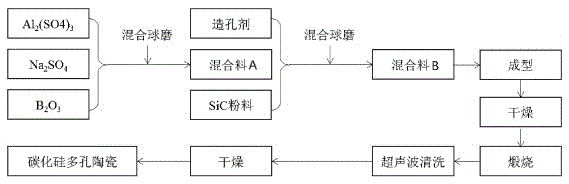

Method used

Image

Examples

Embodiment 1

[0025] First, the Al 2 (SO 4 ) 3 、Na 2 SO 4 and B 2 o 3 The raw materials are compounded according to the molar ratio of 1:4:1 / 6, and the mixture A is obtained through a 120-mesh sieve after mixing and ball milling; then, the mixture A, SiC powder, and carbon powder are mixed in a mass ratio of 8:100 : The ratio of 20 is carried out batching, crosses 120 mesh sieves and obtains mixture B after mixing ball milling; Adopting dry pressing method is that 200Mpa is at pressure, and pressure-holding time is that under the pressing condition of 120s, above-mentioned mixture B is pressed into green body; Then After drying it, place it in an electric furnace, and heat it up to 900°C at a rate of 5°C / min for calcination. After reaching the calcination temperature, it is kept for 3 hours, and then cooled with the furnace; finally, the sample is heated at 80°C. Ultrasonic cleaning with tap water under certain conditions, until the Na in the liquid after cleaning + The content does ...

Embodiment 2

[0028] First, the Al 2 (SO 4 ) 3 、Na 2 SO 4 and B 2 o 3 The raw materials are compounded according to the molar ratio of 1:4:1 / 6, and mixed with ball milling and passed through a 120-mesh sieve to obtain the mixture A; then, the mixture A, SiC powder and graphite powder are mixed in a mass ratio of 10:100 : The ratio of 100 is carried out batching, crosses 120 mesh sieves and obtains mixture B after mixing ball milling; Adopting dry pressing method is that 200Mpa is at pressure, and under the pressing condition that holding time is 90s, above-mentioned mixture B is pressed into green body; Then After drying it, place it in an electric furnace, and heat it up to 1000°C at a rate of 3°C / min for calcination. After reaching the calcination temperature, it is kept for 5 hours, and then cooled with the furnace; finally, the sample is heated at 80°C. Ultrasonic cleaning with tap water under certain conditions, until the Na in the liquid after cleaning + The content does not ex...

Embodiment 3

[0031] First, the Al 2 (SO 4 ) 3 、Na 2 SO 4 and B 2 o 3The raw materials are compounded according to the molar ratio of 1:4:1 / 6, and the mixed material A is obtained by passing through a 120-mesh sieve after mixing and ball milling; then, the mixed material A is mixed with SiC powder and graphite powder in a mass ratio of 2:100 : 0 ratio is carried out batching, crosses 120 mesh sieves and obtains mixture B after mixing ball milling; Adopt dry pressing method to be 150Mpa at pressure, under the pressing condition that holding pressure time is 60s, above-mentioned mixture B is pressed into green body; Then again After drying it, place it in an electric furnace, and heat it up to 1200°C at a rate of 8°C / min for calcination. After reaching the calcination temperature, keep it warm for 5 hours, and then cool it with the furnace; finally, the sample is heated at 80°C. Ultrasonic cleaning with tap water under certain conditions, until the Na in the liquid after cleaning + The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com