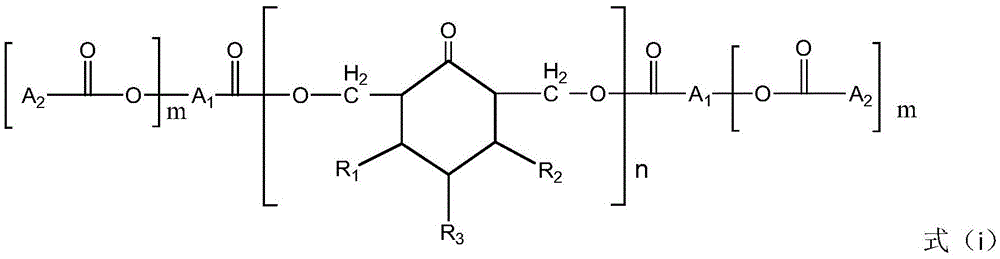

Modified aldehyde-ketone resin as well as preparation method and application thereof

A technology of aldehyde and ketone resin and aldehyde and ketone resin, applied in the field of aldehyde and ketone resin, to achieve high economic benefits, excellent comprehensive performance, and excellent initial drying effect

- Summary

- Abstract

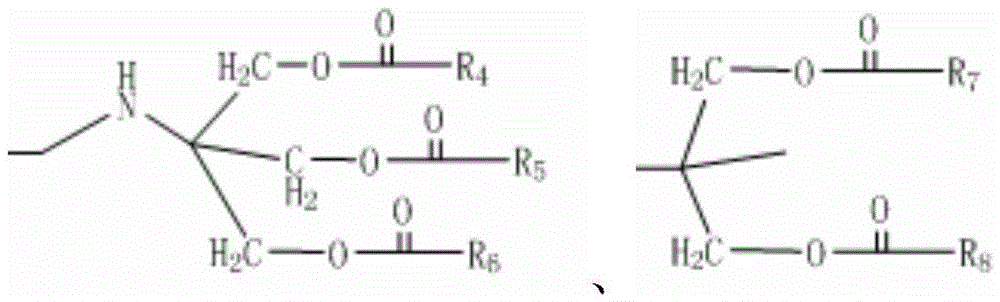

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

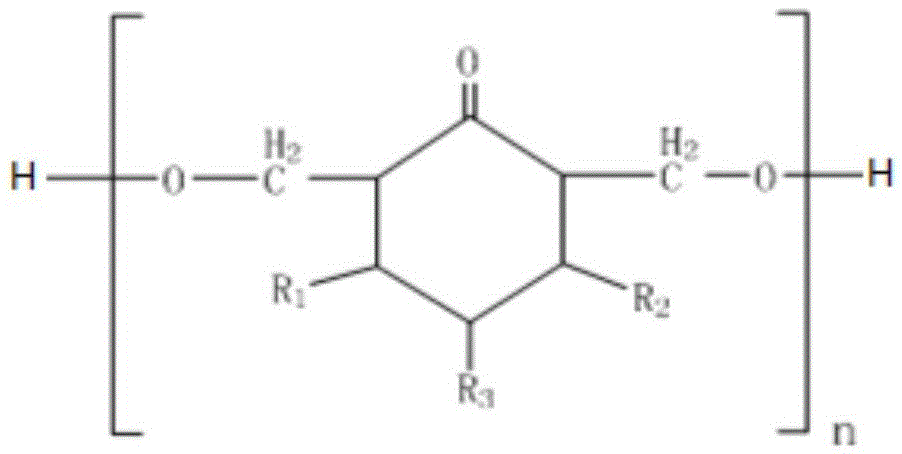

Embodiment 1

[0047] In the reactor, drop into 43.05 parts of methacrylic acid, 2.58 parts of p-toluenesulfonic acid, 84.93 parts of dichloromethane, hydroquinone, gac and 50 parts of silica gel (Guangzhou Chemical Reagent Factory), obtain mixture, control hydroquinone and The contents of activated carbon in the mixture are 200ppm and 150ppm respectively; and fully mixed and stirred evenly; slowly start steam heating, control the heating speed to make the vapor pressure at 0.3Mpa, raise the temperature to 85°C within 1.5h, and maintain this temperature and stir for 20 Minutes; gradually add 33.53 parts of dimethylol propionic acid into the reactor, complete feeding within 3 hours and reflux reaction for 3.5 hours; continue steam heating, keep the steam pressure of the reactor at 0.4Mpa, raise the temperature to 110°C within 1 hour, and mix thoroughly Stir for 30 minutes; dissolve the aldehyde and ketone resin solution with dichloromethane in advance (the aldehyde and ketone resin is KR-120 f...

Embodiment 2

[0053] Put 36.03 parts of acrylic acid, 2.40 parts of methanesulfonic acid, 92.14 parts of toluene, 300 ppm of p-hydroxyanisole, 200 ppm of activated carbon and 40 parts of silica gel (Guangzhou Chemical Reagent Factory) into the reaction kettle, and fully mix and stir; slowly start steam heating , control the heating rate so that its vapor pressure is at 0.5Mpa, raise the temperature to 90°C within 1.5h, and keep stirring at this temperature for 40 minutes; gradually add 29.86 parts of N-[tris(hydroxymethyl)methyl]glycine to the reaction kettle In the middle, the feeding is completed within 3 hours and the reaction is refluxed for 3 hours; the steam heating is continued to keep the vapor pressure of the reactor at 0.7Mpa, and the temperature is raised to 120°C within 1 hour, and fully mixed and stirred for 35 minutes; the aldehyde and ketone resin solution (aldehyde The ketone resin is KR-130 of Changsha Changtai Company; the hydroxyl value is 104mgKOH / g, Mn~1400g / mol; in the ...

Embodiment 3

[0059] Put 36.03 parts of acrylic acid, 1.44 parts of methanesulfonic acid, 73.10 parts of dimethylformamide, 150 ppm of hydroquinone, 350 ppm of activated carbon and 50 parts of silica gel (Guangzhou Chemical Reagent Factory) into the reaction kettle, and fully mix and stir; Start steam heating, control the heating speed so that the vapor pressure is 0.3Mpa, raise the temperature to 90°C within 1.5h, and keep stirring at this temperature for 40 minutes; gradually add 33.53 parts of dimethylolpropionic acid into the reaction kettle, within 3h Complete the feeding and reflux reaction for 5 hours; continue steam heating to keep the vapor pressure of the reactor at 0.5Mpa, raise the temperature to 105°C within 1 hour, and fully mix and stir for 35 minutes; dissolve the aldehyde and ketone resin solution (aldehyde The ketone resin is KR-130 of Changsha Changtai Company; hydroxyl value 104mgKOH / g, Mn~1400g / mol; in the structural formula, R1, R2, R3 are all H, and n is 9; the solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com