Culture method of Aspergillus niger seeds

A culture method and a technology for Aspergillus niger spores are applied in the field of biological fermentation, which can solve the problems that the growth stage cannot be guaranteed, it is difficult to truly reflect the growth state of Aspergillus niger, and the fermentation results are affected, and the invention achieves good timeliness, simple and convenient measurement, and consumption. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

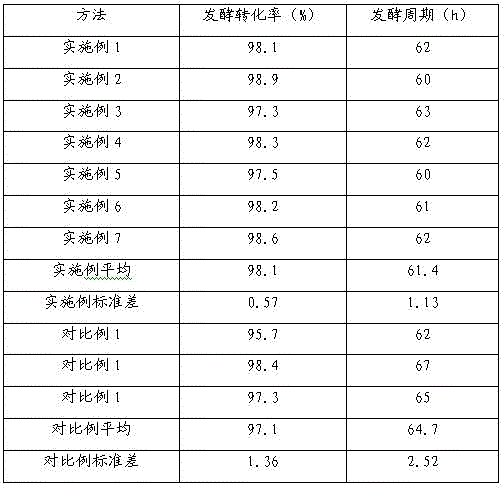

Examples

Embodiment 1

[0033] After the corn is crushed, pass through an 80-mesh sieve; the obtained corn flour and tap water are mixed evenly at a material-to-water ratio of 1:3, the slurry pH is adjusted to 5.8, and the high temperature α-amylase is added at the addition amount of 20U / g corn flour; The obtained slurry was sprayed twice, and a qualified liquefied liquid was obtained after the iodine test was light brown.

[0034] The liquefied liquid is diluted with tap water, and ammonium sulfate is added to prepare a seed culture medium with a total sugar of 10% and a total nitrogen of 0.2%. After sterilizing at 121°C for 20 minutes and cooling to 37°C, insert the Aspergillus niger CICC40021 spore suspension (strain source: CICC preserved strain) to make the concentration of spores 300,000 / ml after inoculation.

[0035] The seed culture conditions are: the temperature is 37℃, the dissolved oxygen concentration and the stirring speed are coupled with feedback control, and the dissolved oxygen solubilit...

Embodiment 2

[0038] After the corn is crushed, pass through an 80-mesh sieve; the obtained corn flour and tap water are mixed evenly at a material-to-water ratio of 1:3, the slurry pH is adjusted to 5.8, and the high temperature α-amylase is added at the addition amount of 20U / g corn flour; The obtained slurry was sprayed twice, and a qualified liquefied liquid was obtained after the iodine test was light brown.

[0039] The liquefied liquid is diluted with tap water, and ammonium sulfate is added to prepare a seed culture medium with a total sugar of 10% and a total nitrogen of 0.2%. After sterilizing at 121°C for 20 minutes and cooling to 37°C, insert the Aspergillus niger CICC40021 spore suspension (strain source: CICC preserved strain) to make the concentration of spores 300,000 / ml after inoculation.

[0040] The seed culture conditions are: the temperature is 37℃, the dissolved oxygen concentration and the air volume are coupled with feedback control, and the dissolved oxygen solubility is...

Embodiment 3

[0043] After the corn is crushed, pass through an 80-mesh sieve; the obtained corn flour and tap water are mixed evenly at a material-to-water ratio of 1:3, the slurry pH is adjusted to 5.8, and the high temperature α-amylase is added at the addition amount of 20U / g corn flour; The obtained slurry was sprayed twice, and a qualified liquefied liquid was obtained after the iodine test was light brown.

[0044] The liquefied liquid is diluted with tap water, and ammonium sulfate is added to prepare a seed culture medium with a total sugar of 12% and a total nitrogen of 0.4%. After sterilization at 121°C for 20 minutes and then cooling to 38°C, the Aspergillus niger CICC40021 spore suspension (strain source: CICC preserved strain) was inserted to make the concentration of spores 400,000 / ml after inoculation.

[0045] The seed culture conditions are: temperature 38°C, dissolved oxygen concentration and stirring speed coupled feedback control, by adjusting the stirring speed to control t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com