Preparation method of instant canned asparagus

A technology for canned asparagus and asparagus, which is applied to the field of preparation of ready-to-eat canned asparagus, can solve the problems of damage and loss of nutrients, short asparagus harvest cycle, poor flavor of asparagus, etc., and achieves functions of metabolism, health preservation, appearance, and increased added value. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

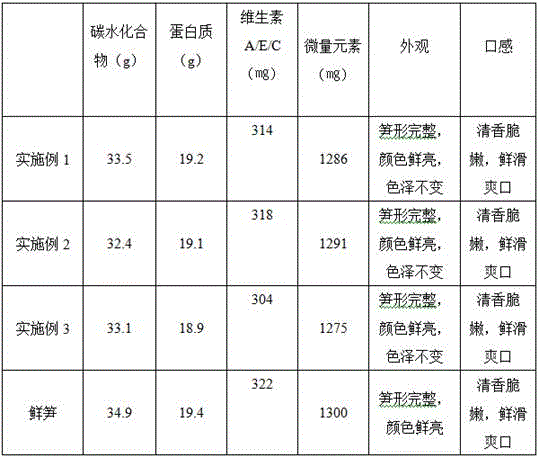

Examples

Embodiment 1

[0020] A preparation method for instant canned asparagus, comprising the following steps:

[0021] 1) Use fresh asparagus as raw material, select fresh asparagus with a stem diameter of 1-3cm, cut off the root, trim it to 8-10cm, and set aside;

[0022] 2) Soak the remaining asparagus waste after selection in step 1) in clear water for 11 hours, then soak in hot water at 90-100°C for 2 minutes, squeeze the juice by centrifugation, filter and collect the filtrate, then add dry rice wine with 8% volume of the filtrate, and then Add tea polyphenols, clove oil and Moringa seed powder with a mass of 0.6% of the filtrate, mix evenly, and obtain a soaking solution for later use; the mass ratio of the tea polyphenols, clove oil and Moringa seed powder is 1:0.8:1.2;

[0023] 3) Soak the trimmed asparagus in step 1) in water, then add a mixed enzyme of neutral cellulase, hemicellulase, pectinase and amylase with a mass ratio of 3:3:1.5:1, and mix well. Soak at 38-46°C for 4 days, take ...

Embodiment 2

[0027] A preparation method for instant canned asparagus, comprising the following steps:

[0028] 1) Use fresh asparagus as raw material, select fresh asparagus with a stem diameter of 1-2cm, cut off the root, trim it to 5-7cm, and set aside;

[0029] 2) Soak the remaining asparagus waste after selection in step 1) in clear water for 10 hours, soak in hot water at 80-90°C for 1 minute, squeeze the juice by centrifugation, collect the filtrate by filtration, and add 5% volume fraction of dry rice wine to the filtrate , then add tea polyphenols, clove oil and Moringa seed powder with a filtrate quality of 0.5%, mix evenly, and obtain a soaking solution for subsequent use; the mass ratio of the tea polyphenols, clove oil and Moringa seed powder is 1:0.8:1 ;

[0030] 3) Soak the trimmed asparagus in step 1) in water, then add a mixed enzyme of neutral cellulase, hemicellulase, pectinase and amylase with a mass ratio of 3:3:1.5:1, mix well, Soak at 38-46°C for 3 days, take it ou...

Embodiment 3

[0034] A preparation method for instant canned asparagus, comprising the following steps:

[0035] 1) Using fresh asparagus as raw material, select fresh asparagus with a stem diameter of 2-3cm, cut off the root, trim it to 8-10cm, and set aside;

[0036] 2) Soak the remaining asparagus waste after selection in step 1) in clear water for 12 hours, soak in hot water at 90-100°C for 2 minutes, squeeze the juice by centrifugation, collect the filtrate by filtration, and add 10% volume fraction of dry rice wine to the filtrate , then add tea polyphenols, clove oil and Moringa seed powder with a filtrate quality of 0.8%, mix evenly, and obtain a soaking liquid for subsequent use; the mass ratio of the tea polyphenols, clove oil and Moringa seed powder is 1:0.8:1.5 ;

[0037] 3) Soak the trimmed asparagus in step 1) in water, then add a mixed enzyme of neutral cellulase, hemicellulase, pectinase and amylase with a mass ratio of 3:3:1.5:1, mix well, Soak at 38-46°C for 5 days, take...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com