Zinc soap-mannitol composite heat stabilizer for polyvinyl chloride and preparing method and application thereof

A compound heat stabilizer and polyvinyl chloride technology, applied in the field of preparation, zinc soap-mannitol compound heat stabilizer for polyvinyl chloride, can solve the problems of easy precipitation, high melting point of pentaerythritol, poor PVC compatibility, etc., and achieve coloring Good performance, good internal and external lubricity, excellent lubricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Zinc stearate (18.96g, 0.03mol) and mannitol (5.47g, 0.03mol) were added to a 500mL three-necked flask at a molar ratio of 1:1, mechanically stirred at a stirring rate of 100rpm, and under a nitrogen atmosphere, The reaction was carried out in an oil bath at 200° C. for 2 hours. After cooling, the product is ground into fine powder, and sieved with a 200-mesh steel sieve to obtain the zinc stearate-mannitol compound.

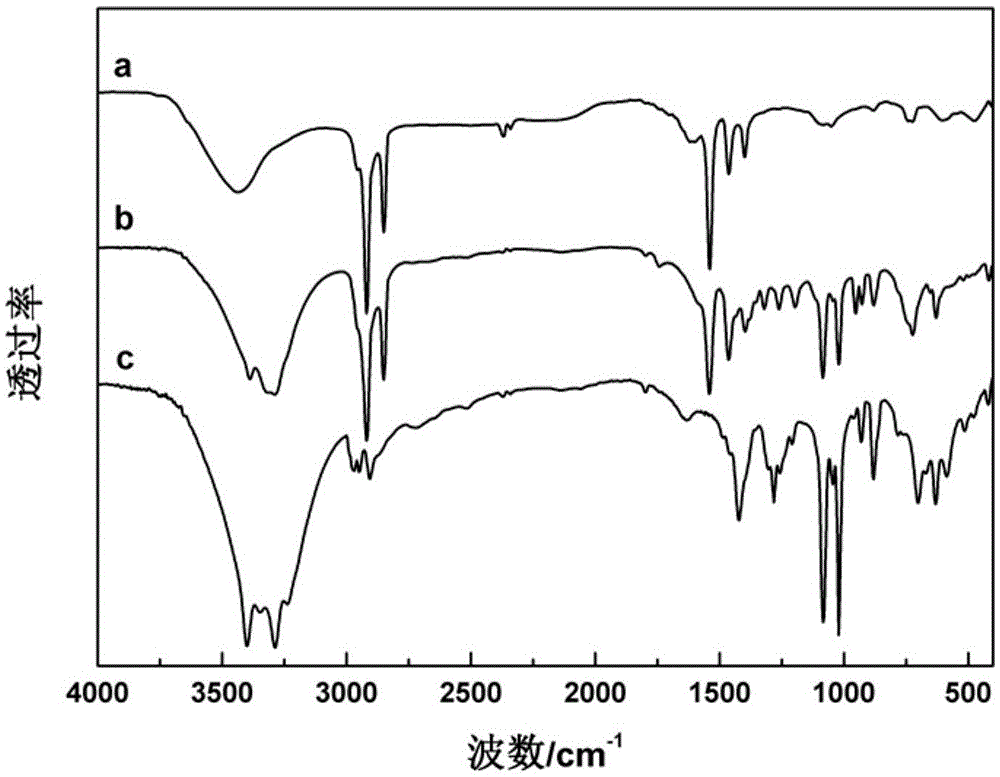

[0029] Fourier transform infrared spectrometer was used to characterize the chemical structure of zinc stearate, mannitol and zinc stearate-mannitol complex, the results are as follows figure 1 shown. Potassium bromide grinding tablet method is used to prepare samples, and the scanning range is 4000~400cm -1 .

[0030] figure 1 Among them, a is the infrared spectrum of zinc stearate, b is the infrared spectrum of zinc stearate-mannitol complex, and c is the infrared spectrum of mannitol. Such as figure 1 As shown in a, 2848cm -1 and 2918cm -1 It i...

Embodiment 2

[0032] Zinc stearate (18.96g, 0.03mol) and mannitol (1.82g, 0.01mol) were added into a 500mL three-necked flask at a molar ratio of 3:1, mechanically stirred at a stirring rate of 50rpm, and under a nitrogen atmosphere, React in an oil bath at 180°C for 4 hours. After cooling, the product is ground into fine powder, and sieved with a 200-mesh steel sieve to obtain the zinc stearate-mannitol compound.

Embodiment 3

[0034] Zinc laurate (13.92g, 0.03mol) and mannitol (0.55g, 0.003mol) were added into a 500mL three-necked flask at a molar ratio of 10:1, mechanically stirred at a stirring rate of 250rpm, under a nitrogen atmosphere, in React in an oil bath at 140°C for 8 hours. After cooling, the product was ground into a fine powder and sieved with a 200-mesh steel sieve to obtain the zinc laurate-mannitol complex.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com