Silicate green emitting phosphor and preparation method thereof

A green phosphor, silicate technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of harsh preparation conditions, complex synthesis process, and high synthesis cost, and achieve good chemical stability and thermal stability. The effect of simple synthesis process and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

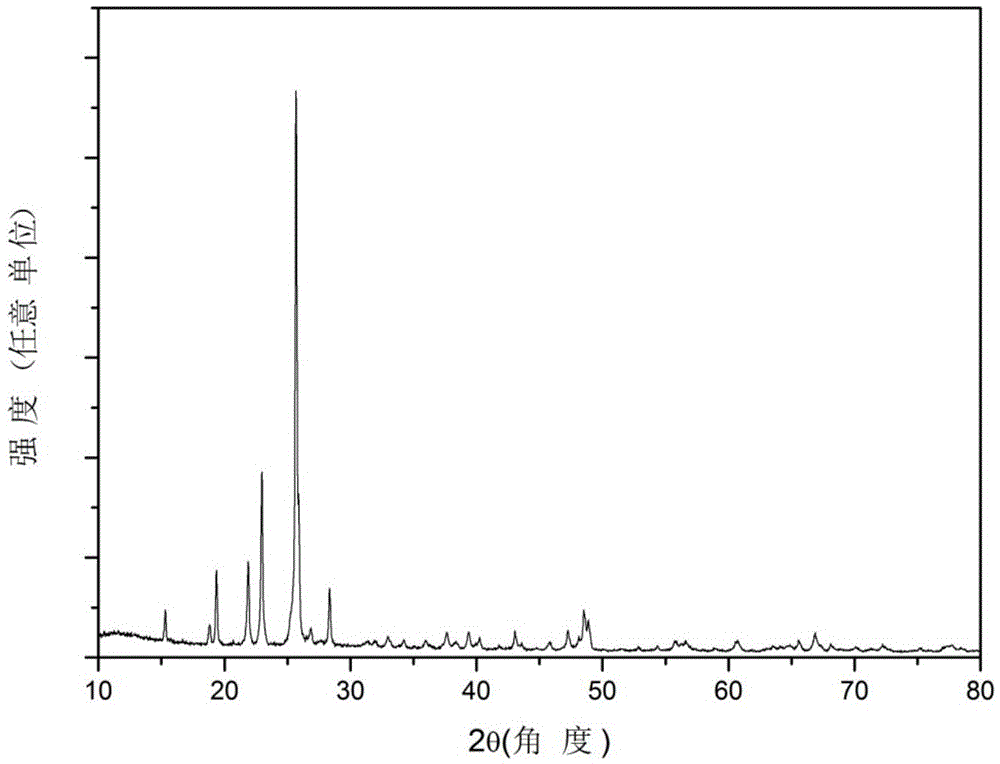

Embodiment 1

[0024] According to Li 2 O·Al 2 o 3 4SiO2 2 : 0.005Eu 2+ Weigh Li 2 CO 3 、Al 2 o 3 , SiO 2 and Eu 2 o 3 , the molar ratio between them is 1:1:4:0.0025. After fully grinding and mixing, place it in a corundum crucible, then put it into a tube furnace and bake it at 1000°C for 7 hours under a nitrogen-hydrogen mixed atmosphere, and then cool it to At room temperature, a silicate green phosphor was obtained.

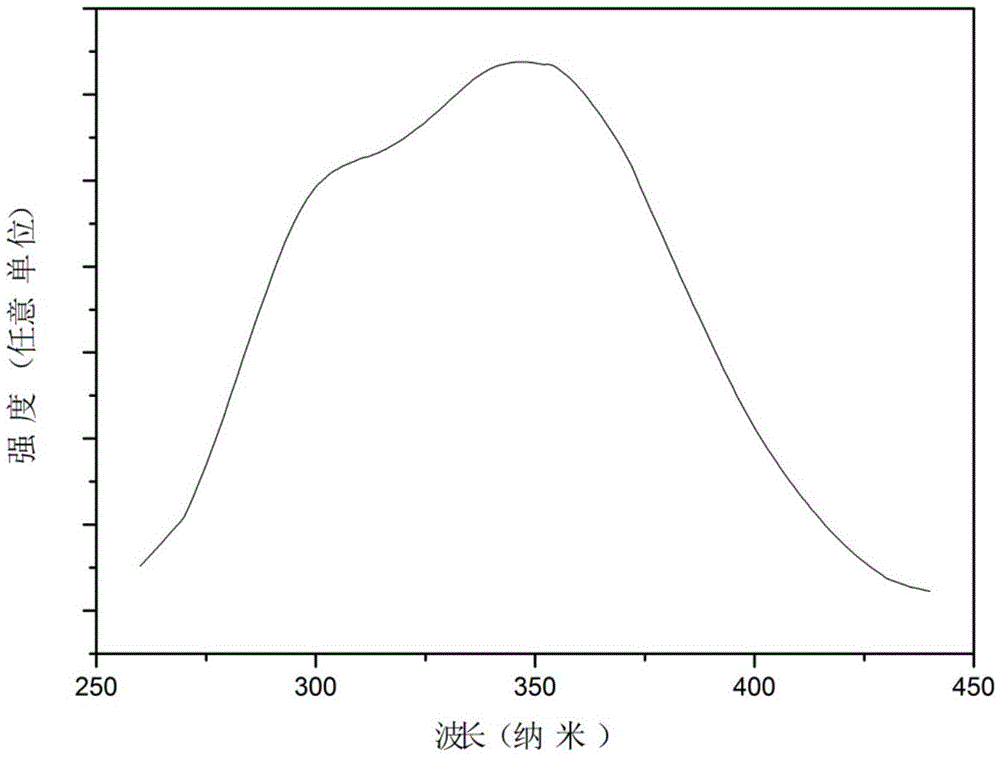

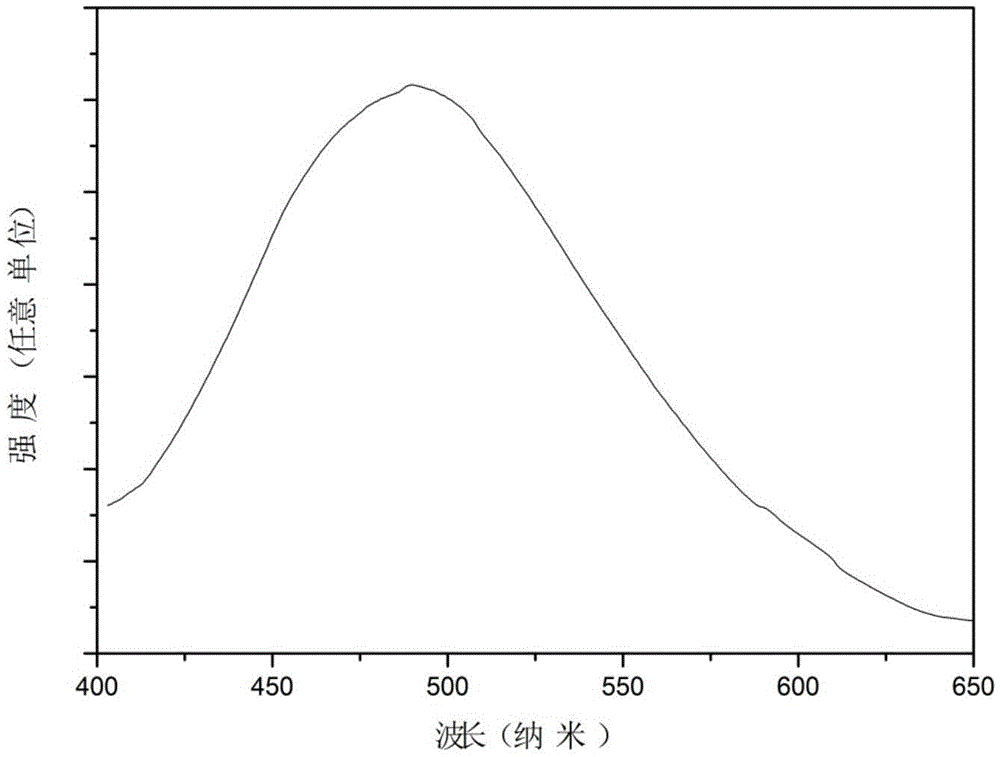

[0025] From figure 1 It can be seen from the figure that the excitation spectrum of the phosphor powder in this embodiment is a broad spectrum, covering the ultraviolet and violet light regions, the excitation peak is located near 360nm, and the spectral peak is high, indicating that the phosphor powder of this embodiment can be effectively excited by the ultraviolet and violet light chips . When the excitation wavelength of the emission spectrum is 360nm, from figure 2 It can be seen from the figure that the emission of the phosphor powder in this embodiment...

Embodiment 2

[0027] According to Li 2 O·Al 2 o 3 4SiO2 2 : 0.01Eu 2+ Weigh Li 2 CO 3 、Al 2 o 3 , SiO 2 and Eu 2 o 3 , the molar ratio between them is 1:1:6:0.005. After fully grinding and mixing, place it in a corundum crucible, then put it into a tube furnace and bake at 1100°C for 5 hours under a nitrogen-hydrogen mixed atmosphere, and then cool to At room temperature, a silicate green phosphor was obtained.

[0028] The excitation spectrum of the phosphor powder in this embodiment is a wide spectrum, covering the ultraviolet and violet light regions, and the excitation peak is located near 360nm, with a high spectral peak, indicating that the phosphor powder of this embodiment can be effectively excited by the ultraviolet and violet light chips. When the excitation wavelength of the emission spectrum is 360nm, the emission of the phosphor powder in this embodiment is the broadband green light emission of divalent europium, and the emission peak is located near 500nm, indicati...

Embodiment 3

[0030] According to Li 2 O·Al 2 o 3 4SiO2 2 : 0.1Eu 2+ Weigh Li 2 CO 3 、Al 2 o 3 , SiO 2 and Eu 2 o 3 , the molar ratio between them is 1:1:4:0.05. After fully grinding and mixing, place it in a corundum crucible, then put it into a tube furnace and bake it at 1200°C for 2 hours in a nitrogen-hydrogen mixture atmosphere, and then cool it down. to room temperature to obtain silicate green phosphor.

[0031] The excitation spectrum of the phosphor powder in this embodiment is a wide spectrum, covering the ultraviolet and violet light regions, and the excitation peak is located near 360nm, with a high spectral peak, indicating that the phosphor powder of this embodiment can be effectively excited by the ultraviolet and violet light chips. When the excitation wavelength is 360nm, the emission of the phosphor powder in this embodiment is the broadband green light emission of divalent europium, and the emission peak is near 500nm, indicating that the phosphor powder in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com