Biodegradable lubricant oil

A biodegradable, lubricating oil technology, applied in lubricating compositions, petroleum industry, base materials, etc., can solve the problems that ordinary lubricating oil cannot be degraded, pollute the environment, etc., and achieve high market application prospects, high viscosity, and thick oil film. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

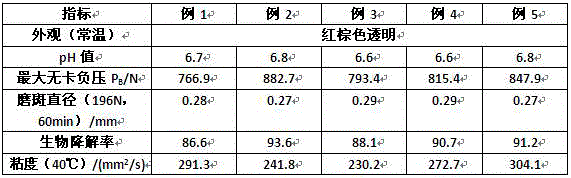

Examples

Embodiment 1

[0035] A biodegradable lubricating oil:

[0036] (1) 35 parts by weight of rapeseed oil, 30 parts by weight of isoheptyl tridecyl dioic acid, and 20 parts by weight of castor oil are added to the blending kettle with a stirrer, and the stirring temperature is 60 ° C, stirring Speed 600rpm, stirring time 20 minutes;

[0037] (2) the montmorillonite that is 5.0 by weight, the zirconia that is 2.0 by weight, the di-tert-butyl-p-cresol antioxidant anti-adhesive agent that is 1.5 by weight, the polymethacrylate that weight is 0.8 and Add 0.6 parts by weight of methyl silicone oil into the blending kettle of step (1), stir at a temperature of 60°C, a stirring speed of 900 rpm, and a stirring time of 40 minutes;

[0038] (3) Packing the oil product evenly stirred in the blending kettle in step (2) into a finished product to obtain the required biodegradable lubricating oil.

Embodiment 2

[0040] A biodegradable lubricating oil:

[0041] (1) 40 parts by weight of rapeseed oil, 35 parts by weight of isoheptyl tridecyl dioic acid, and 25 parts by weight of castor oil are added to the blender with a stirrer, and the stirring temperature is 60 ° C, stirring Speed 720rpm, stirring time 20 minutes;

[0042] (2) the montmorillonite of 3.0 parts by weight, the zirconia of 2.0 parts by weight, the N-phenyl-α-aniline of 1.8 parts by weight, the polyisobutylene and polyvinyl n-butyl ether of 1.0 parts by weight and 1.0 parts by weight of simethicone oil are added to the blending kettle of step (1), the stirring temperature is 60°C, the stirring speed is 1200 rpm, and the stirring time is 40 minutes;

[0043] (3) Packing the oil product evenly stirred in the blending kettle in step (2) into a finished product to obtain the required biodegradable lubricating oil.

Embodiment 3

[0045] A biodegradable lubricating oil:

[0046] (1) 36 parts by weight of rapeseed oil, 32 parts by weight of tridecyl dioic acid isoheptyl alcohol, castor oil of 23 parts by weight are added in the blending kettle with stirrer, stirring temperature is 60 ℃, stirring Speed 660rpm, stirring time 20 minutes;

[0047] (2) the montmorillonite that is 3.5 by weight, the zirconium oxide that is 1.8 by weight, the sulfur phosphorus bis-octyl zinc salt antioxidant and anticorrosion agent and N-phenyl-α-aniline that weight portion is 1.6, weight 0.9 parts by weight of polyvinyl n-butyl ether, polyacrylate and 0.7 parts by weight of methyl silicone oil are added to the blending kettle of step (1), the stirring temperature is 60°C, the stirring speed is 1100 rpm, and the stirring time is 40 minutes;

[0048] (3) Packing the oil product evenly stirred in the blending kettle in step (2) into a finished product to obtain the required biodegradable lubricating oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com