White board with high tensile strength and manufacture method thereof

A white board paper, high-resistance technology, applied in the field of papermaking, can solve the problems of low stretchability, low tensile coefficient, and low formaldehyde content, and achieve the effects of increasing tensile index, low transparency, and improving stretchability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

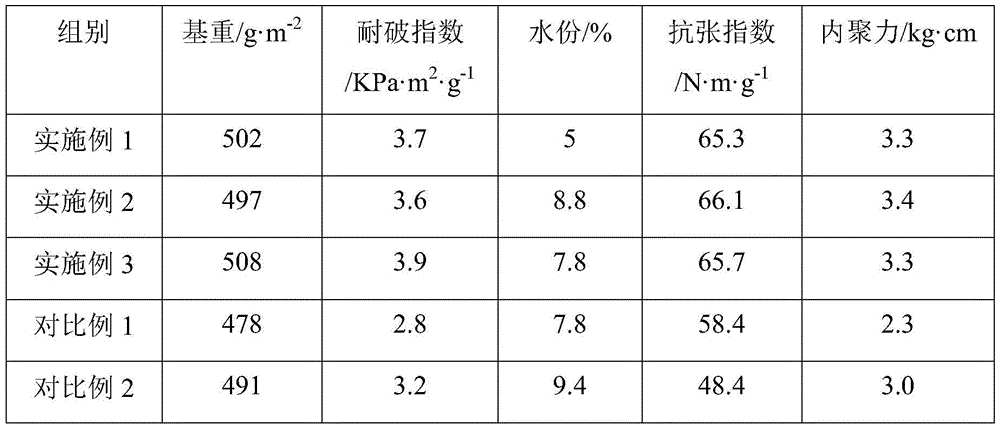

Examples

Embodiment 1

[0031] A high-strength white board paper is made of the following raw materials in parts by weight: 100 parts of mixed fiber, 6 parts of tea extract and 10 parts of mango leaf extract. Wherein, 100 parts of the mixed fibers include poplar wood fiber, bamboo fiber and camphor wood fiber with a mass ratio of 15:2:10, and the length of the poplar wood fiber is 0.98mm and the width is 0.02mm.

[0032] The preparation method of the tea extract is as follows: drying and pulverizing the tea leaves, adding them to an aqueous acetone solution for reflux extraction, filtering after the first extraction, performing 2 reflux extractions on the filter residue, combining the filtrates from 3 reflux extractions, and depressurizing The acetone is removed by distillation, the filtrate is concentrated, and freeze-dried to obtain the product; wherein, the amount of acetone added each time is 3 times the quality of the tea leaves.

[0033] The high-strength white board paper also includes a bleac...

Embodiment 2

[0044] A high-strength whiteboard is made from the following raw materials in parts by weight: 105 parts of mixed fiber, 8 parts of tea extract and 15 parts of mango leaf extract. Wherein, 105 parts of the mixed fibers include poplar wood fiber, bamboo fiber and camphor wood fiber with a mass ratio of 16:3:10, and the length of the poplar wood fiber is 0.98 mm and the width is 0.02 mm.

[0045]The preparation method of the tea extract is as follows: drying and pulverizing the tea leaves, adding them to an aqueous acetone solution for reflux extraction, filtering after the first extraction, performing 2 reflux extractions on the filter residue, combining the filtrates from 3 reflux extractions, and depressurizing The acetone is removed by distillation, the filtrate is concentrated, and freeze-dried to obtain the product; wherein, the amount of acetone added each time is 5 times the quality of the tea leaves.

[0046] The high-strength white board paper also includes a bleaching...

Embodiment 3

[0057] A high-strength whiteboard is made of the following raw materials in parts by weight: 102 parts of mixed fiber, 7 parts of tea extract and 12 parts of mango leaf extract. Wherein, 102 parts of the mixed fibers include poplar wood fiber, bamboo fiber and camphor wood fiber with a mass ratio of 15:2:10, and the length of the poplar wood fiber is 0.98 mm and the width is 0.02 mm.

[0058] The preparation method of the tea extract is as follows: drying and pulverizing the tea leaves, adding them to an aqueous acetone solution for reflux extraction, filtering after the first extraction, performing 2 reflux extractions on the filter residue, combining the filtrates from 3 reflux extractions, and depressurizing The acetone is removed by distillation, the filtrate is concentrated and freeze-dried to obtain the product; wherein, the amount of acetone added each time is 4 times the quality of the tea leaves.

[0059] The high-strength white board paper also includes a bleaching a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Freeness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com