Transparent paper and method for preparing same by repeatedly coating surface

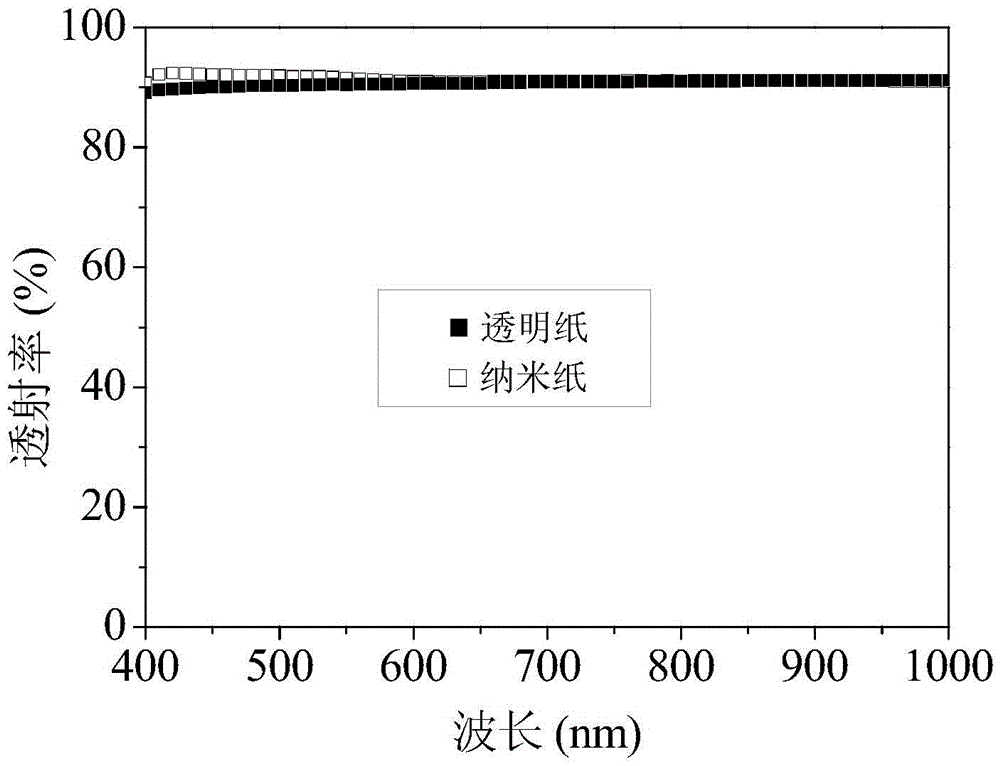

A surface coating, transparent paper technology, applied in paper coatings, special paper, paper and other directions, can solve the problems of high cost, application limitation, cellulose crystal structure damage, etc., and achieve short production cycle, low cost and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The method for rapidly preparing transparent paper by multiple coating methods comprises the following steps and process conditions:

[0033] (1) Papermaking of base paper: using broad-leaved wood dissolving pulp board as raw material, beating first, the beating degree is 40SR°, and then the pulp after beating is copied into base paper, quantitatively 60g / m 2 ;

[0034] (2) raw material drying: drying the base paper made in step (1) until the moisture content is lower than 2%;

[0035] (3) Coating process: the ionic liquid N-ethylimidazolium hydrogen phosphite (EMIMMeOPO 2 H) coating on the base paper surface dried in step (2). The loading amount of ionic liquid on the surface of base paper is 5g / m 2 ;

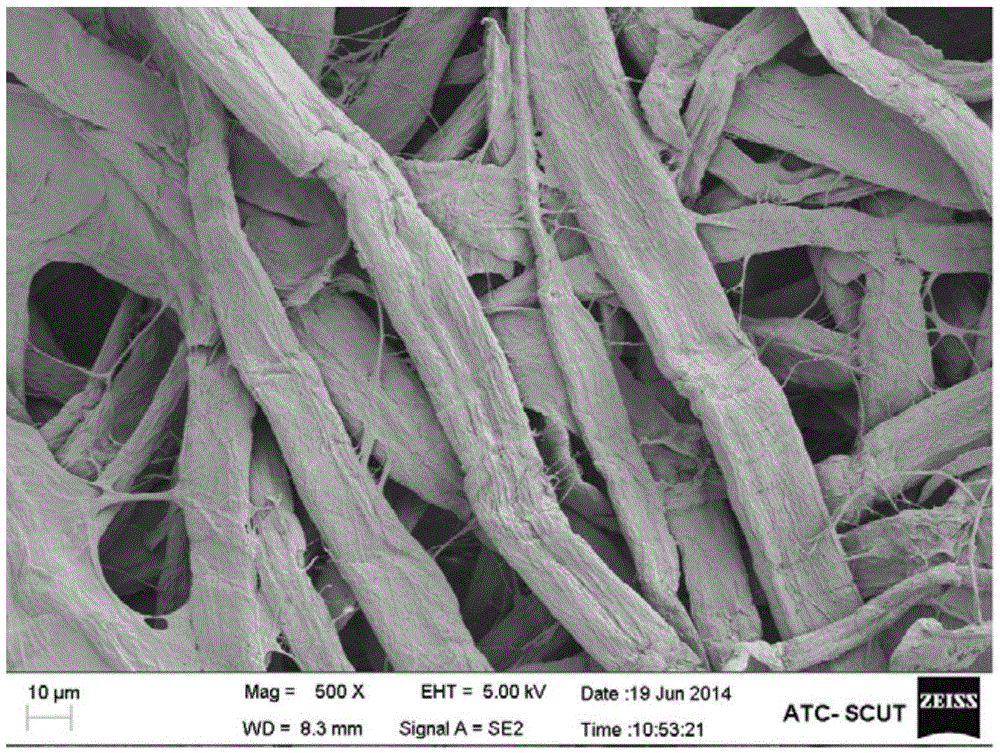

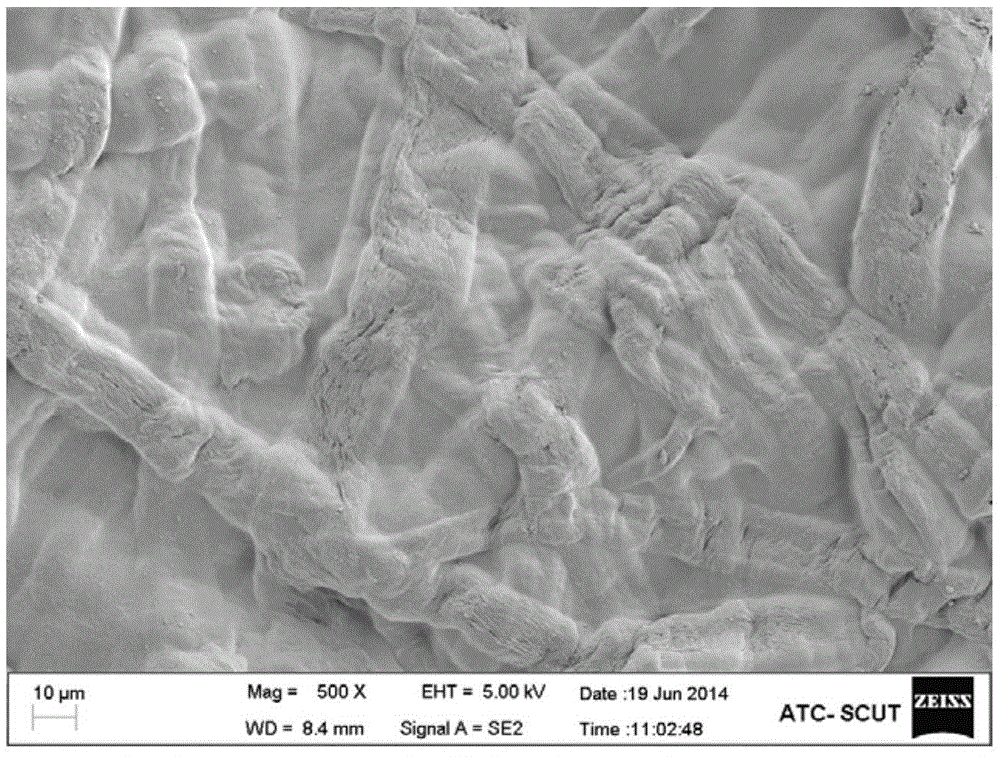

[0036] (4) Partial dissolution of the base paper surface: put the base paper coated in step (3) on a continuous flat press with a temperature of 100°C and a pressure of 1 MPa for 10 minutes to fully swell and partially dissolve the plant fibers on the base paper sur...

Embodiment 2

[0044] The method for rapidly preparing transparent paper by multiple coating methods comprises the following steps and process conditions:

[0045] (1) Papermaking of base paper: using broad-leaved wood dissolving pulp board as raw material, beating first, the beating degree is 50SR°, and then the pulp after beating is copied into base paper, quantitatively 50g / m 2 ;

[0046] (2) raw material drying: drying the base paper made in step (1) until the moisture content is lower than 2%;

[0047](3) Coating process: prepare N-N dimethylacetamide / lithium chloride (DMAC / LiCl) solution with a ratio of 10:1, and apply the prepared solution on the surface of step (2) by spin coating Dry base paper surface. The loading amount of DMAC / LiCl solution on the base paper surface is 20g / m 2 ;

[0048] (4) Partial dissolution of the base paper surface: put the base paper coated in step (3) on an intermittent flat press with a temperature of 70°C and a pressure of 5 MPa for 30 minutes to ful...

Embodiment 3

[0054] The method for rapidly preparing transparent paper by multiple coating methods comprises the following steps and process conditions:

[0055] (1) Papermaking of base paper: using broad-leaved wood dissolving pulp board as raw material, beating first, the beating degree is 60SR°, and then the pulp after beating is copied into base paper, quantitatively 40g / m 2 ;

[0056] (2) raw material drying: drying the base paper made in step (1) until the moisture content is lower than 2%;

[0057] (3) Coating process: the ionic liquid 1-allyl-3-hexylimidazolium chloride (AHIMCl) is coated on the surface of the base paper dried in step (2) by curtain coating. The loading amount of ionic liquid on the surface of base paper is 10g / m 2 ;

[0058] (4) Partial dissolution of the base paper surface: put the base paper coated in step (3) on a continuous flat press with a temperature of 100°C and a pressure of 2 MPa for 5 minutes to fully swell and partially dissolve the plant fibers on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com