A kind of latex modified asphalt composition particle and preparation method thereof

A technology of modified asphalt and composition, which is applied in the field of petroleum asphalt, which can solve the problems of increasing the difficulty of asphalt dispersion, and achieve the effects of increasing the range of viscoelasticity, good affinity, and improving compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

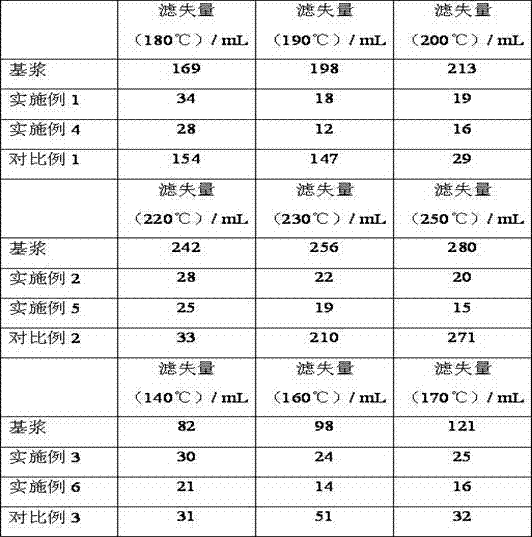

Embodiment 1

[0045] Take 100g of high softening point asphalt II (softening point is 180°C) and 70g of kerosene in a container, stir at room temperature (25°C) for 30 minutes, and mix thoroughly to obtain a mother liquor; mix 60g of high softening point asphalt I (softening point 200℃, the average particle size is 60μm) and the mother liquor are mixed in the reactor, and the compressed air is introduced, the gas inlet pressure is 0.15 MPa, the reactor temperature is kept at 180~190℃, stirred for 100 minutes, discharged, and cooled to obtain High softening point asphalt mixture;

[0046] Add 100g low-temperature embrittlement-treated high-softening point asphalt mixture (low-temperature embrittlement conditions: temperature -25°C, time 8 hours), 4g hydrotalcite and 1.5g sodium lignosulfonate into a high-speed pulverizer, mix and pulverize for 25s , to obtain high softening point asphalt particles, denoted as A1, with an average particle size of 85 μm.

Embodiment 2

[0048] Take 100g of high softening point asphalt II (softening point of 220°C) and 50g of diesel oil in a container, stir at room temperature at 50°C for 30 minutes, and mix thoroughly to obtain a mother liquor; put 100g of high softening point asphalt I (softening point of 250 ℃, the average particle size is 70μm) and the mother liquor are mixed in the reactor, and compressed air is introduced, the gas inlet pressure is 0.25 MPa, the reactor temperature is kept at 230~240℃, stirred for 70 minutes, discharged, and cooled to obtain a high softening point asphalt mixture;

[0049] Add 100g of low-temperature brittle high-softening point asphalt composition (the embrittlement treatment conditions are the same as in Example 1), 5g of graphite, 1g of cetyltrimethylammonium bromide and 3g of carboxymethyl starch into a high-speed pulverizer , mixed and crushed for 20s to obtain high softening point asphalt granules, denoted as A2, with an average particle size of 100 μm.

Embodiment 3

[0051] Take 100g of high softening point pitch II (softening point of 140°C) and 100g of gasoline in a container, stir at room temperature at 80°C for 35 minutes, and mix thoroughly to obtain a mother liquor; put 120g of high softening point pitch I (softening point of 170 ℃, the average particle size is 70μm) and the mother liquor are mixed in the reactor, and compressed air is introduced, the gas inlet pressure is 0.3 MPa, the reactor temperature is kept at 150~160°C, stirred for 60 minutes, and then heated to 165°C, stirred 10 minutes, discharging, cooling to obtain high softening point asphalt mixture;

[0052] Add 100g of asphalt composition, 6g of montmorillonite and 0.5g of octadecyltrimethylammonium bromide into a high-speed pulverizer, mix and pulverize for 30s to obtain high softening point asphalt granules, denoted as A3, and its average particle size is 80 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com