Plasma pretreatment and dyeing method of wool fabric

A dyeing method and plasma technology, applied in the field of fabrics, can solve the problems of poor hand feeling of wool, unsatisfactory wool fiber microstructure, unsatisfactory dye uptake performance, etc., and achieve smooth hand feel, high dye uptake and color fastness, The effect of improving the dyeing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

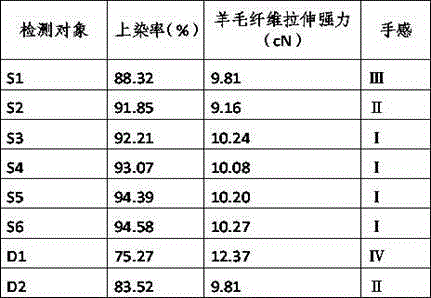

Examples

Embodiment 1

[0026] The wool fabric plasma pretreatment dyeing method of embodiment 1 (abbreviated as S1, the following embodiments are the same) comprises the following steps:

[0027] S1: Prepare the dye mixing solution, which contains reactive dyes, sodium sulfate, soluble rare earth chloride, pH regulator and water, and the weight ratio of wool fabric to reactive dyes is 1:0.02; the soluble chlorinated The rare earth element in the rare earth is at least one selected from light rare earth and medium rare earth, the weight ratio of wool fabric to rare earth chloride is 1:0.001, and the pH value of the dye mixing solution is 4.5;

[0028] S2: Plasma treatment of wool fabric in a low-temperature atmosphere;

[0029] S3: Dip the fabric obtained in S2 into the dye mixture solution obtained in S1, raise the temperature to 30°C, keep it warm for 2 hours, then raise the temperature to 70°C again, keep it warm for 1 hour, and then cool down;

[0030] S4: Take out the fabric and dry it naturall...

Embodiment 2

[0033] The difference between embodiment 2 and embodiment 1 is: S1: configure the dye mixing solution, including reactive dyes, sodium sulfate, soluble rare earth chloride, pH regulator and water in the dye mixing solution, the weight of wool fabric and reactive dyes The ratio is 1:0.045; the rare earth element in the soluble rare earth chloride is at least one selected from light rare earth and medium rare earth, the weight ratio of wool fabric to rare earth chloride is 1:0.005, the pH of the dye mixture solution Value is 5.5;

[0034] S2: Plasma treatment of wool fabric in a low-temperature atmosphere;

[0035] S3: Dip the fabric obtained in S2 into the dye mixture solution obtained in S1, raise the temperature to 35°C, keep it warm for 5 hours, then raise the temperature to 85°C again, keep it warm for 3 hours, and then cool down;

[0036] S4: Take out the fabric and dry it naturally, then wash, dehydrate and dry it several times to obtain the dyed wool fabric.

[0037] In ...

Embodiment 3

[0039] The difference between embodiment 3 and embodiment 1 is: S1: configure the dye mixing solution, including reactive dyes, sodium sulfate, soluble rare earth chloride, pH regulator and water in the dye mixing solution, the weight of wool fabric and reactive dyes The ratio is 1:0.032; the rare earth element in the soluble rare earth chloride is at least one selected from light rare earth and medium rare earth, the weight ratio of wool fabric to rare earth chloride is 1:0.003, the pH of the dye mixture solution The value is 4;

[0040] S2: Plasma treatment of wool fabric in a low-temperature atmosphere;

[0041] S3: Dip the fabric obtained in S2 into the dye mixture solution obtained in S1, raise the temperature to 32°C, keep it warm for 3.5 hours, then raise the temperature to 77°C again, keep it warm for 2 hours, and then cool down;

[0042] S4: Take out the fabric and dry it naturally, then wash, dehydrate and dry it several times to obtain the dyed wool fabric.

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com