High-voltage and high-rate type lithium cobalt oxide cathode material and preparation method thereof

A cathode material, lithium cobalt oxide technology, applied in the field of high-voltage high-rate lithium cobalt oxide cathode material and its preparation, can solve the problems of unstable structure, capacity fading, and inability to exhibit high-voltage and high-rate performance, etc. Convenience, rate-type energy improvement, and excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

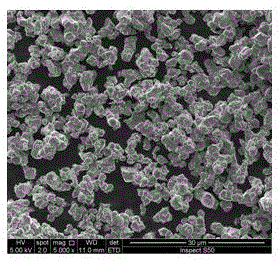

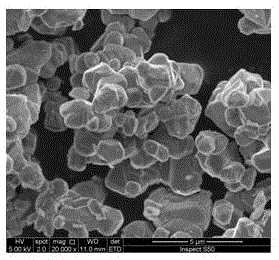

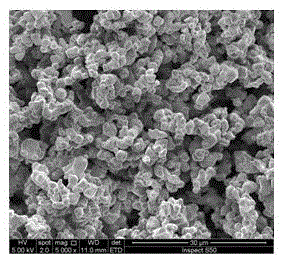

Image

Examples

Embodiment 1

[0029] Embodiment 1: The preparation method of the high-voltage high-rate lithium cobalt oxide positive electrode material adopts the following process steps.

[0030] (1) Lithium carbonate and cobalt oxide are added according to Li / Co=1.02 (mole), and magnesium carbonate is added according to Mg / Co=0.005 (mole); the above mixture is fully mixed with a three-dimensional mixer or a super mixer to obtain Disperse the primary mixture evenly.

[0031] (2) Sinter the primary mixture in an air atmosphere at 950-980°C for 12 hours; the resulting primary sintered product is crushed by air flow or high-speed rotating equipment, and sieved to obtain lithium cobaltate, with an average particle size (D50) of 2 ~4μm.

[0032] (3) Dissolve aluminum isopropoxide in absolute ethanol according to Al / Co=0.005 (mole), then add tetraisobutyl titanate according to Ti / Co=0.005 (mole), stir well and add the above-mentioned lithium cobaltate , fully stirred and mixed, and dried to obtain a secondar...

Embodiment 2

[0036] Embodiment 2: The preparation method of the high-voltage and high-rate lithium cobalt oxide positive electrode material adopts the following process steps.

[0037] (1) Lithium carbonate and cobalt oxide are added according to Li / Co=1.00 (mole), and magnesium carbonate is added according to Mg / Co=0.002 (mole); the above mixture is fully mixed with a three-dimensional mixer or a super mixer to obtain Disperse the primary mixture evenly.

[0038] (2) The primary mixture is sintered in an air atmosphere at 930-950°C for 10 hours; the obtained primary sintered product is crushed by airflow or high-speed rotating equipment, and sieved to obtain lithium cobaltate, and the average particle size (D50 ) is 2 to 4 μm.

[0039] (3) Dissolve aluminum isopropoxide in absolute ethanol according to Al / Co=0.003 (mole), then add tetraisopropyl titanate according to Ti / Co=0.003 (mole), stir well and add the above cobalt acid Lithium, stirred and mixed thoroughly, and dried to obtain a ...

Embodiment 3

[0043] Embodiment 3: The preparation method of the high-voltage and high-rate lithium cobalt oxide positive electrode material adopts the following process steps.

[0044] (1) Lithium carbonate and cobalt oxide are added according to Li / Co=1.03 (mole), and magnesium carbonate is added according to Mg / Co=0.01 (mole); the above mixture is fully mixed with a three-dimensional mixer or a super mixer to obtain Disperse the primary mixture evenly.

[0045] (2) Sinter the primary mixture in an air atmosphere at 900-920°C for 14 hours; the obtained primary sintered product is crushed by air flow or high-speed rotating equipment, and sieved to obtain lithium cobaltate, and the average particle size (D50 ) is 2 to 4 μm.

[0046] (3) Dissolve aluminum n-pentoxide in isopropanol according to Al / Co=0.001 (mole), then add tetraisooctyl titanate according to Ti / Co=0.01 (mole), stir well and add the above-mentioned cobalt acid Lithium, stirred and mixed thoroughly, and dried to obtain a sec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com