Urea resin foam particle matrix and processing method thereof

A technology of urea-formaldehyde resin foam and processing method, which is applied in the directions of planting substrate, botanical equipment and method, medium, etc., can solve the problems of insufficient macroporosity, destruction of secondary main roots and main fine roots, and high consumption, and achieves a simple processing process. , the effect of reducing the amount of use and reducing the water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] A kind of urea-formaldehyde resin foam particle matrix, is made up of the raw material uniform mixing of following percentage by weight:

[0022] Urea-formaldehyde resin foam particles 20-50%, nutritional powder 40-60%;

[0023] The main raw material of the nutrient powder is one or more of industrial and agricultural organic solid wastes such as straw, sawdust, peat, distiller's grains, fungus chaff, sludge, rice husk, biogas residue; the preparation method of the nutrient powder: Add VT-aerobic fermentation bacteria to the above main raw materials, the mass ratio of VT-aerobic fermentation bacteria to the above main raw materials is 1: (1000-2000), use large piles of fermentation for 25-35 days, then age, dry and crush , to obtain nutritional powder.

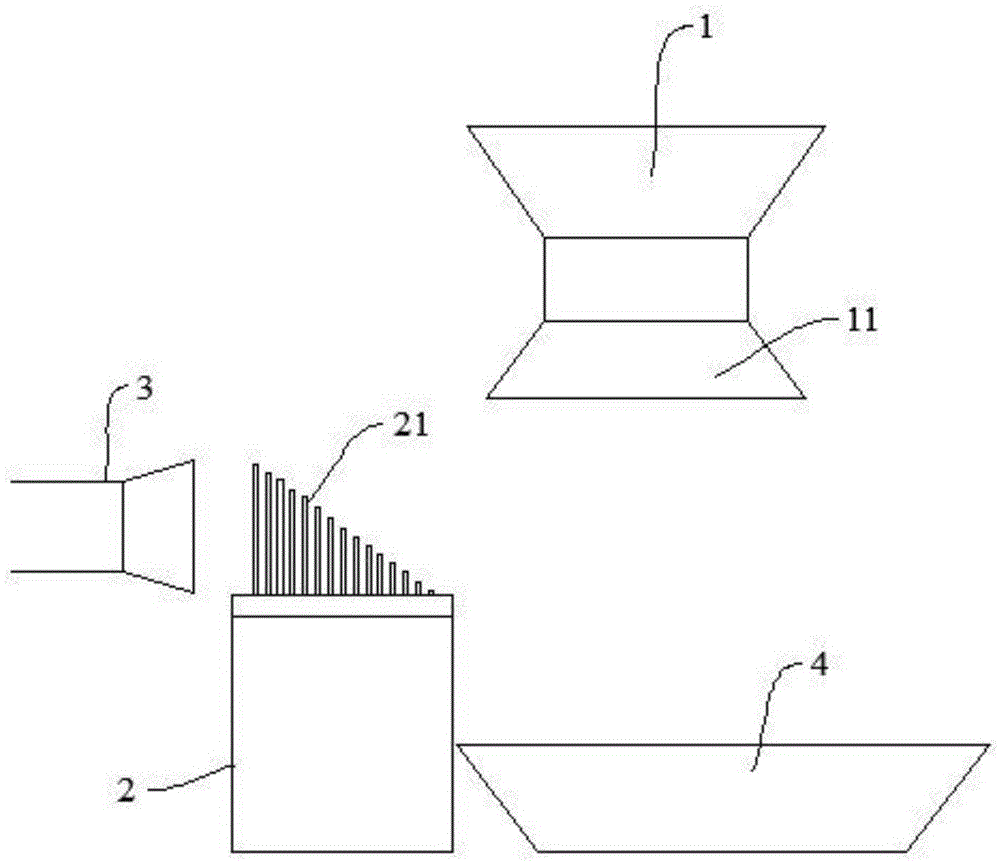

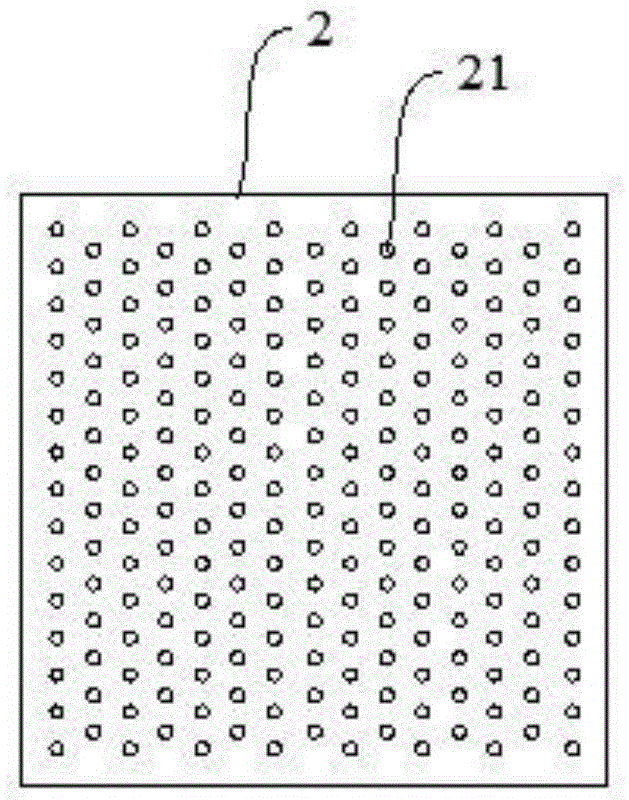

[0024] Such as figure 1 , 2 Shown, a kind of processing method of urea-formaldehyde resin foam particle substrate comprises the following steps:

[0025] Step 1: Preparation of nutrient powder; add VT-aerobic fermen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com