Waste slurry conditioning agent system, and application method thereof

A technology for conditioning treatment and waste mud, which is used in biological sludge treatment, mining wastewater treatment, dewatering/drying/concentrating sludge treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

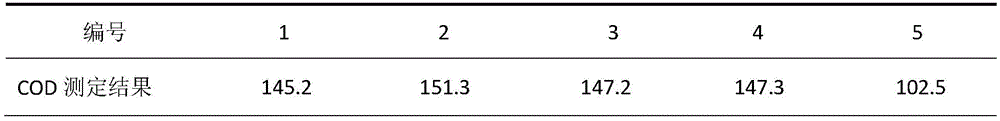

Embodiment 1

[0017] Add 500 mg / L of polyaluminum iron silicate to the waste mud spilled during oil field drilling in turn, and add 100 mg / L of oxidizing agent sodium ferrate after 30 seconds. After mixing for 20 minutes, add 0.2% surface-adhered Nut shell particles of microorganisms, mixed well. Then the mud mixture is processed with a screw stacker, and the residue obtained is used as a standardized well site construction roadbed.

[0018] Among them, the nut shell particles are soaked in the mixture of Pseudomonas fluorescens and Rhodotorula viscosus and then used after drying in a cool place. The composition of the bacterial solution is: add 10 6 / ml Pseudomonas fluorescens 2.5mL, add 10 6 Individual / ml Rhodotorula viscosus 1.5mL.

Embodiment 2

[0020] Others are the same as embodiment 1. The dosage of polyaluminum ferric silicate is 400mg / L. After 25 seconds, add the oxidant sodium ferrate 150mg / L. After mixing for 20 minutes, add 0.5% nut shell particles with microorganisms attached to the surface, and mix well. Then the mud mixture is processed with a screw stacker, and the residue obtained is used as a standardized well site construction roadbed.

[0021] Among them, the nut shell particles are soaked in the mixture of Pseudomonas fluorescens and Rhodotorula viscosus and then used after drying in a cool place. The composition of the bacterial solution is: add 10 8 / ml Pseudomonas fluorescens 2.0mL, add 10 8 Individual / ml Rhodotorula viscosus 1.0mL.

Embodiment 3

[0023] Others are the same as embodiment 1. The dosage of polyaluminum ferric silicate is 300mg / L. After 25 seconds, 200mg / L of sodium ferrate, an oxidizing agent, is added. After mixing for 15 minutes, add 0.3% nut shell particles with microorganisms attached to the surface, and mix well. Then the mud mixture is processed with a screw stacker, and the residue obtained is used as a standardized well site construction roadbed.

[0024] Among them, the nut shell particles are soaked in the mixture of Pseudomonas fluorescens and Rhodotorula viscosus and then used after drying in a cool place. The composition of the bacterial solution is: add 10 8 / ml Pseudomonas fluorescens 2.5mL, add 10 8 Individual / ml Rhodotorula viscosus 2.0mL.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com